Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

We work in partnership with our customers and our aim, by simplifying our spring terminology, is to ensure all customers secure the right spring for the right application at the right price.

Below is an A to Z snapshot of common terms, which we hope acts as a piece of educational support in your spring toolkit – wherever you are in the world.

A form of heat treatment increasing the plasticity of wire.

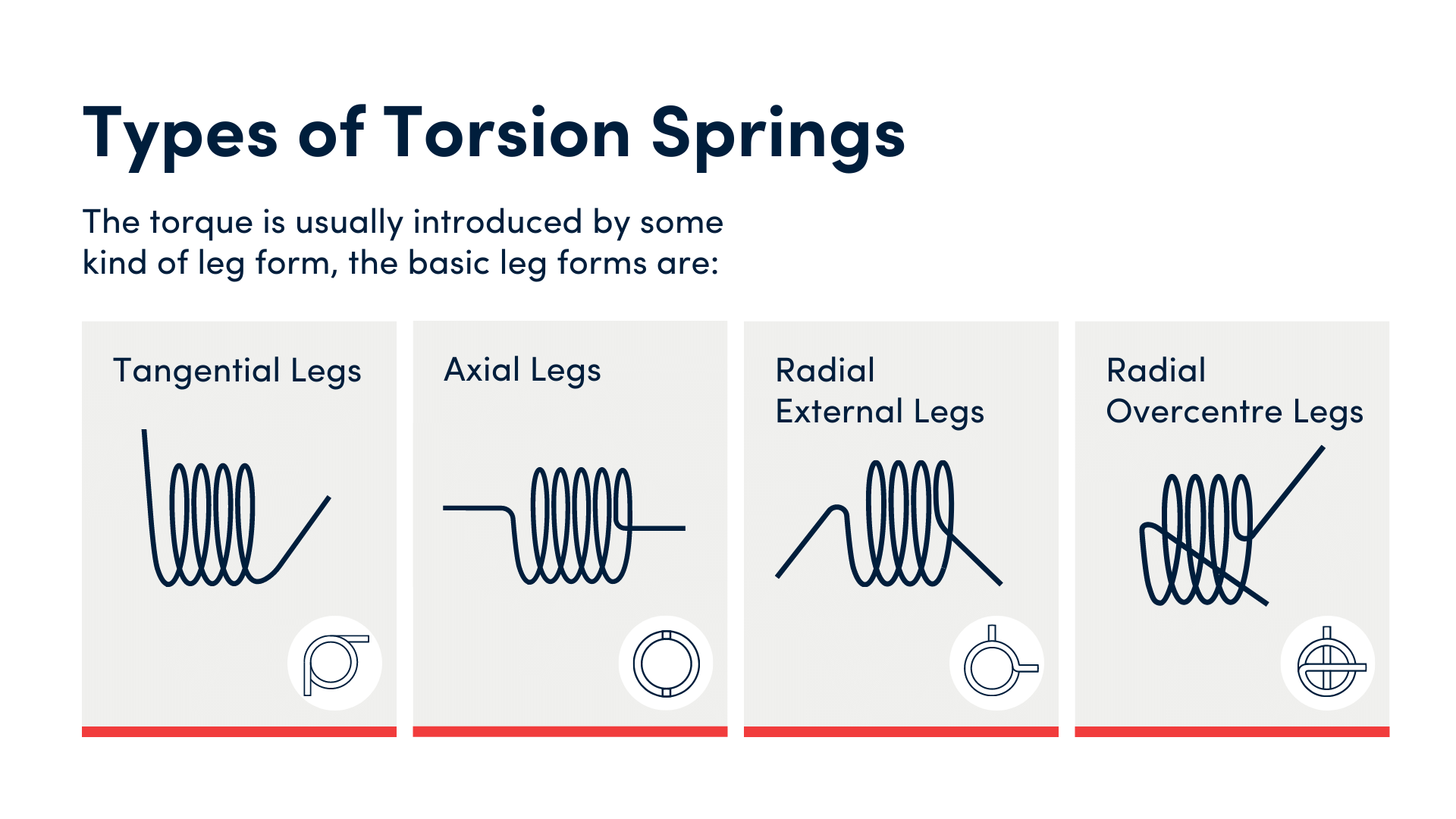

The location of the tension spring hooks/loops or torsion spring legs to each other.

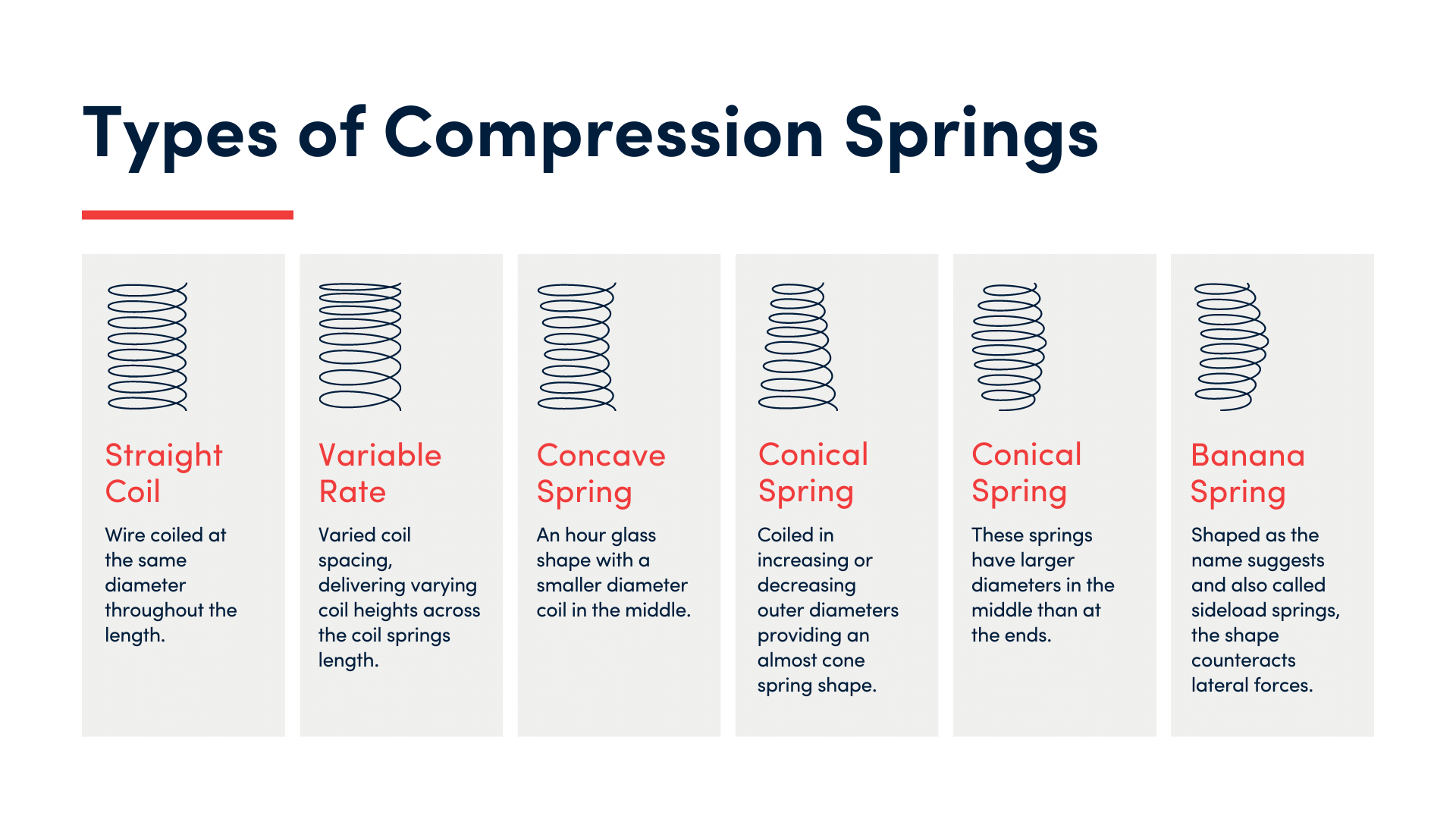

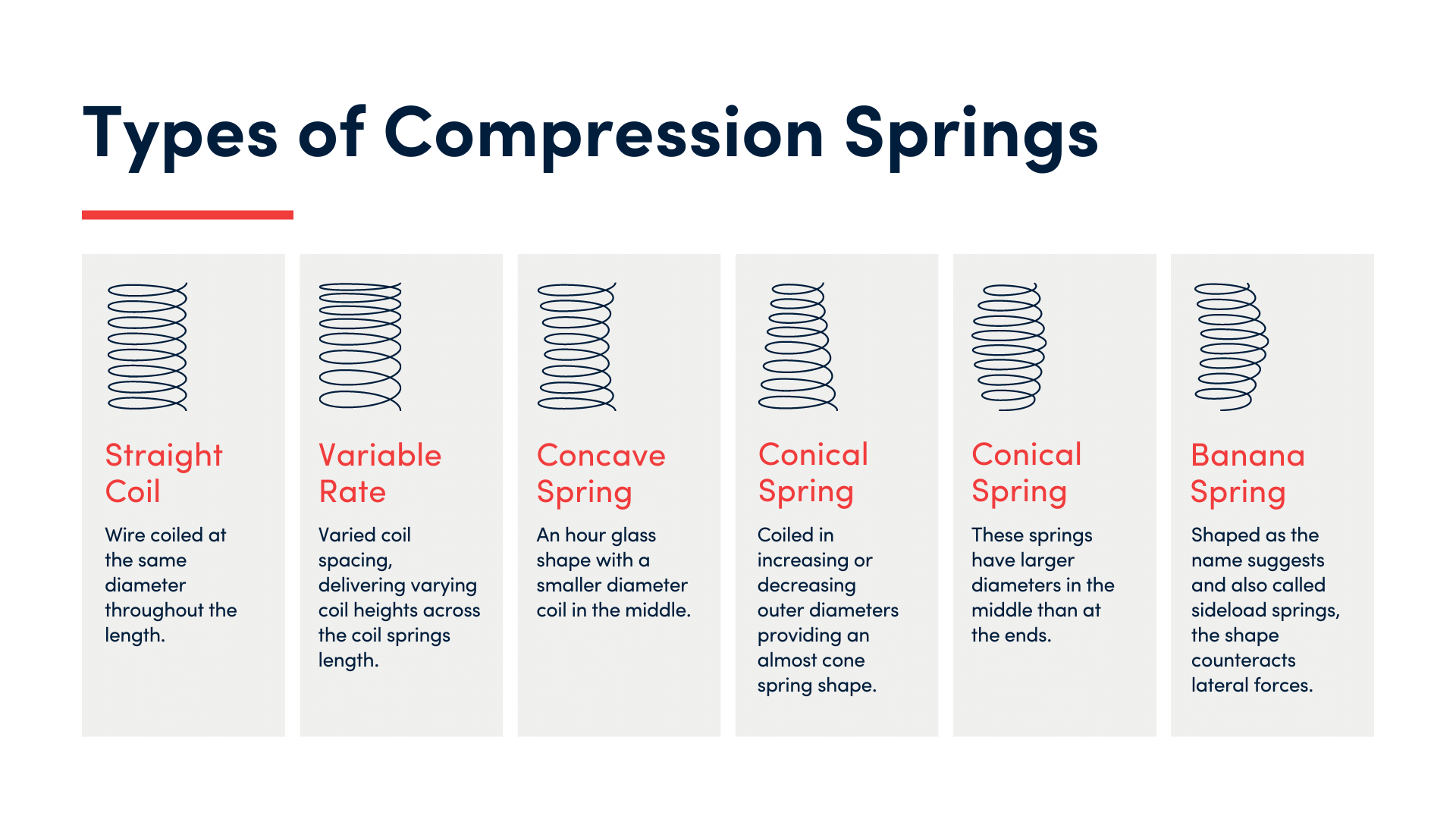

A spring shaped like a banana. Also called a sideload spring – the shape counteracts lateral forces.

See convex.

A predictable point at which a compression spring will bend (buckle) laterally.

Another term for heat treatment is usually applied to post-plating processes.

Compression springs designed for automotive suspension systems.

Coiling using pre-hardened wire and then stress relieving via heat treatment to remove detrimental stresses introduced via coiling. Used for wire diameters up to <22mm. Find out more about cold coiling.

A compressed helix shape allows resistance to compressive forces. Find out more about compression springs.

A spring with a larger diameter in the middle than at the ends.

An hourglass shape with a smaller diameter coil in the middle.

Coiled in increasing or decreasing outer diameters, providing an almost cone shape.

Where the ends of the compression spring are progressively closed so that the end of the coil tip touches the first coil.

As in closed ends (see above) but with the addition of a ground flat surface that enables the spring to have a flat load bearing surface.

See solid height.

Springs in which the wire of the coiled portion is touching, generally tension and torsion springs.

The number of coils in a spring’s length.

When some or all of a compression springs coils are touching under compression.

A time dependant and permanent deflection increases at a constant load resulting in decreased forces. With a constant load applied, the spring will compress more over time.

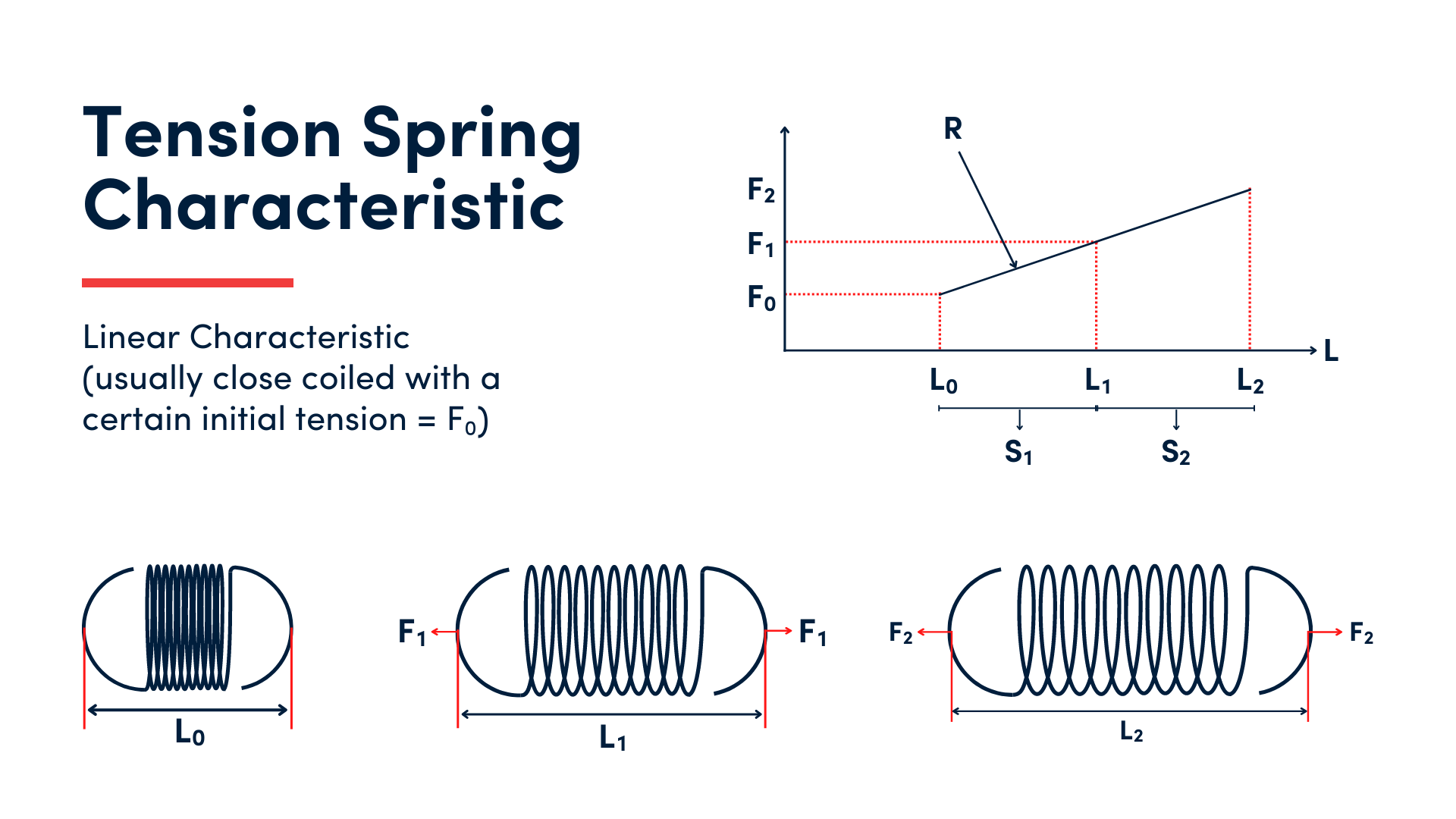

The distance over which a spring is compressed from one point to another, I.E. Fl to l1, l1 to l2.

A spring with a pitch geometry that allows the transition from the original rate to a higher rate at a defined transition point.

The property of spring-forming materials allows them to bend and return to their original shape. The maximum value is called the elastic limit.

The angular value between two legs of an un-loaded torsion spring.

The measure of the expected life of spring, usually measured in cycles per million.

The number of cycles per second a spring operates.

The length of a spring, when not loaded.

The finishing of the ends of spring by grinding to create a flat load-bearing surface. Usually, 270° of the end coil is ground flat.

Process in which to change the properties of a spring material or relieve detrimental stresses.

With wire coiling diameters of up to 65mm, heavy-duty springs are the largest and strongest of the coil spring range and are designed and manufactured to manage the extreme demands of their application. Find out more about heavy springs.

Tension springs feature hook and loop end formed from the spring body.

See concave spring.

See compression spring.

The shape of a compression spring.

The process of heating wire to approximately 900 degrees celsius, coiling, then quenching in oil and tempering, allowing extremely large diameter spring material to be coiled and tight index coiling to be achieved. Learn more about hot coiling.

The force required to separate the closed coils of a tension spring.

The inside measurement of a coil spring body.

Force given at a specified length or angle.

The measurement of the coil spring body to the centre of the wire, e.G. Id + 1 wire diameter.

A factor of rigidity of spring material measured in kn/mm2.

Two or more springs are ‘nested,’ I.E. A smaller spring sits inside the inner diameter (id) of a larger spring. This provides increased force/rate over a smaller length.

Compression spring ends to maintain the open pitch and does not meet the next coil.

As open ends but with a portion ground flat to the axis of the spring.

The distance between each coil in an open wound spring, such as compression springs. See variable pitch and dual rate pitch.

Compression spring with the end coils reduced in diameter to the centre of the body.

Electro-statically applied polymer powder which is then cured to form a high-strength flexible coating.

Process in which a spring has an additional finish applied for beneficial properties, usually to aid corrosion resistance.

The process of forming spring wire by annealing and then rapidly quenched in either molten lead or air @ 500°c. This creates a very fine grain structure that has both high strength and good ductility.

See open ends.

When a compression spring is compressed to a solid length to intentionally take the material past, it’s the elastic limit and introduces plastic deformation. This aligns the beneficial stresses in the material to actually help the spring achieve a longer fatigue life. Pre-setting also reduces the amount of loss of length in service.

See pre-stress (above).

A rate that increases in proportion to increased deflection of a compression spring

Spring force gave over a defined deflection, I.E. 200 n/mm, 100lb/f.

Influenced by temperature/design stress/time, relaxation is the gradual decrease of force from a spring with no appreciable change in spring rate.

A stress that is introduced during any working of the material, e.G. Coiling or forming a torsional leg bend. See cold coiling.

A method of introducing beneficial compressive stress to the material's surface. This increases fatigue life by stopping the formation of cracks that will grow and lead to failure.

See pre-stress.

A change of length by overstressing the material past the material elastic limit. To take a set on a compression spring would mean a permanent and irreversible loss of length.

The ratio of the mean coil diameter to the wire diameter.

The height of a compression spring when fully compressed. See coil bound.

Software used to calculate spring designs and associated stresses/fatigue performance.

Ratio of length to mean diameter.

The measurement in degrees of the spring ends @ 90° to the spring axis.

See ground ends.

Heat treatment removes the detrimental residual stresses introduced by forming the spring.

The relation between minimum and maximum stress.

Also known as an extension spring, coiled close together and designed to give a pull force through an end fitting or loop when extended. Find out more about tension springs.

A coiled spring designed to have a rotational or twisting motion that exerts a force. Find out more about torsion springs.

A force as a product of a change in a rotational motion. See torsion spring.

Heat treatment to reduce the hardness of hardened steel back to below a critical level. See hot coiling.

The number of coils in the spring, normally decimalised I.E. 5.75.

The amount of available deflection from a compression spring. See solid height.

A description of a varied geometry spring. See dual rate, progressive rate.

The distance between the outer edges of wire material.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.