The choice of cold or hot coiling is predominantly determined by the size of the wire needing to be coiled. At Lesjöfors Heavy Springs, our experts in Finland & Sweden are masters of the hot coiling process.

So, let’s look at each term's definition and outline the differences.

What is Cold Coiling?

Cold coiling is a process used to produce springs by winding wire around a given shape at room temperature. Unlike hot coiling, which involves heating the metal to high temperatures to increase its malleability, cold coiling works the metal at or near room temperature. Cold coiling wire is typically made from high-carbon steel or stainless steel, although other materials can also be used depending on the application.

What is hot coiling?

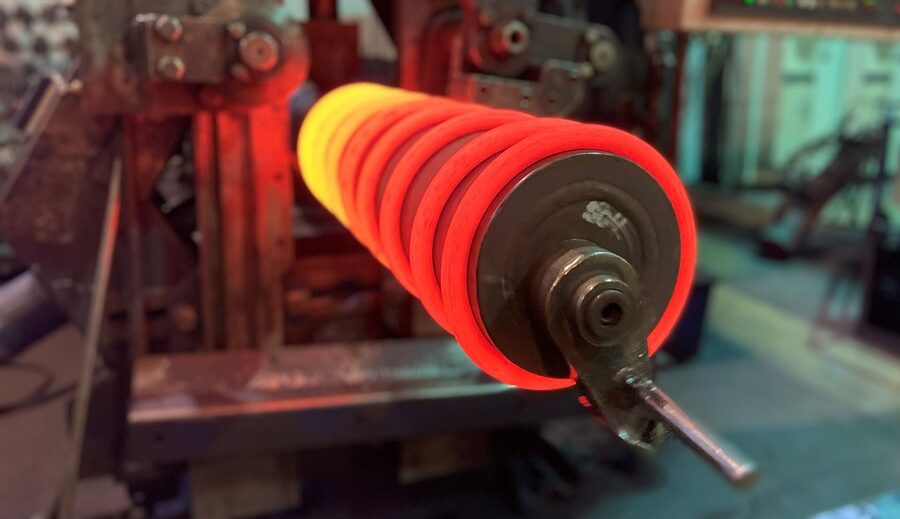

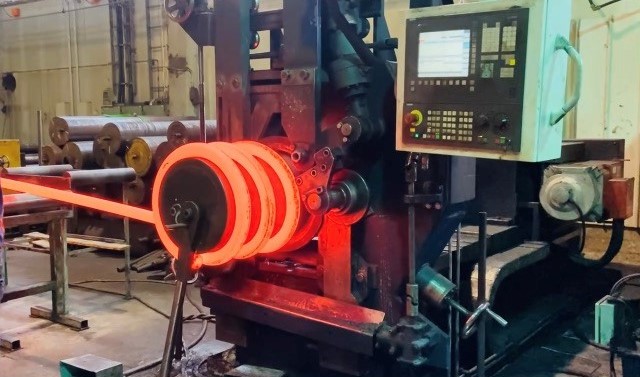

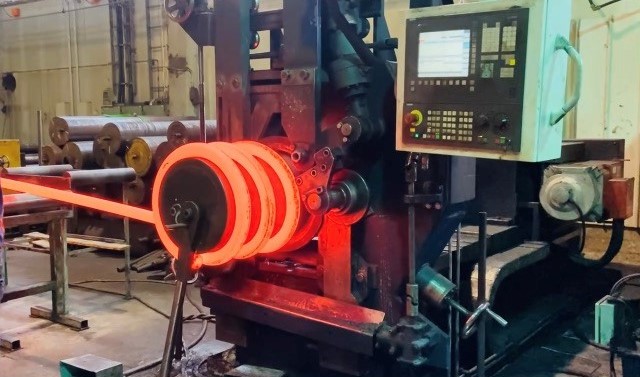

Hot coiling is a process for producing springs from metal wire or rods. It typically involves higher temperatures than those used in cold coiling, between 850 °C and 1,100°C. While the material is hot and more ductile, it is wound around a mandrel to form the spring. Hot coiling uses materials such as certain alloys of steel, which are difficult to work at room temperature due to their high strength or brittleness. These materials can be more easily shaped when heated because their ductility improves significantly at higher temperatures.

What is the difference between hot coiling and cold coiling?

The main differences between

cold and hot coiling include the temperature at which the metal is worked, the types of materials used, tolerances enabled, size of the wire being coiled, surface finish and cost factors. Here is a quick overview of each of the differences.

| Difference |

Cold Coiling |

Hot Coiling |

| Temperature |

Coiled at room temperature |

Coiled between 850 °C and 1,100°C. |

| Materials |

High-carbon steel, stainless steel, and other metals |

High-strength steels and alloys |

| Tolerances |

Allows for tighter tolerances |

Reduced dimensional variations |

| Size of Wire |

Very fine sizes up to 30 mm |

Allows up to 65mm wire diameters |

| Surface Finish |

Allows for better surface finish |

Potential for scale formation on the metal's surface |

| Cost |

Can be more cost-effective and faster for producing small to medium-sized springs |

Increases production costs and time but is necessary for manufacturing larger springs |

Applications of Cold & Hot Coiled Springs

Cold Coiled Springs

Cold-coiled springs are used in a range of applications where precision, high strength, and elasticity are required. These include automotive, electronics, and medical device applications. A wire that has already been heat-treated is commonly cold-coiled as its material is already at peak strength. This allows for numerous spring and wire forms, plus functions and is commonly manufactured by many. However, this restricts the availability of large wire diameters and small indexes.

Hot Coiled Springs

Hot coiled springs with a wide wire diameter are commonly seen in the oil and gas, mining, and rail industries. Hot winding at extreme heat allows up to 65mm wire diameters to be coiled. The wire to heated to approximately 900 degrees Celsius, quenched in oil and then tempered to complete the heat treatment. This allows the spring material to be coiled to the specifications required - more often than not in extreme environments for heavy industry applications.

Our Expertise - Masters of Springs

Our expertise is coiling wire in a soft state and then heat-treating it to its final strength after coiling. This enables larger wire diameters and smaller indexes, which is a core focus for our automotive,

agriculture,

motorsport and

power generation customers.

Your spring, your choice. Our experts across Heavy Springs are on hand to advise on the best

material, plus

design and manufacture for your spring's lifetime and purpose.