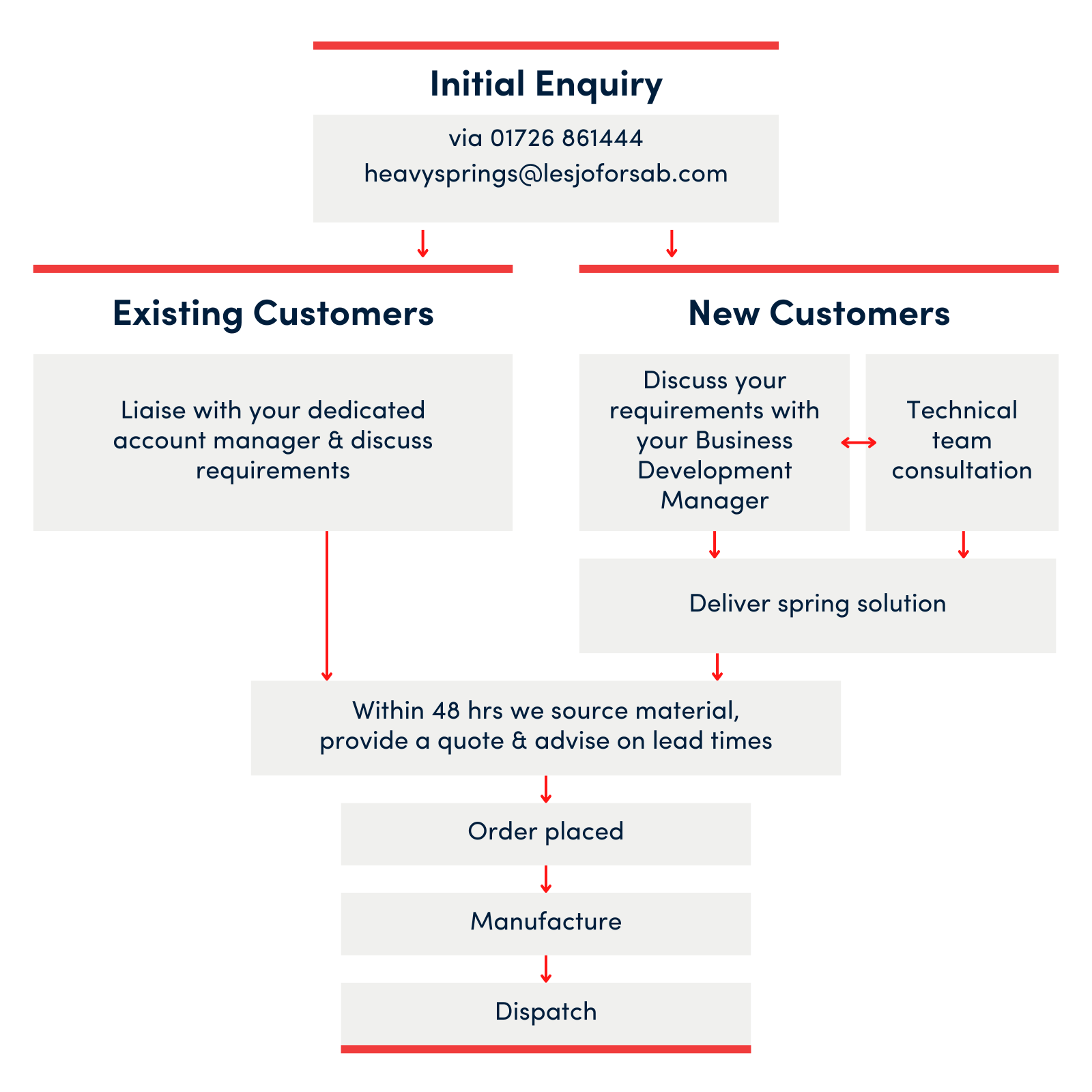

Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

Whether you are looking for a custom coil spring for an oil rig or a suspension spring for a vehicle, Lesjöfors’ expert engineers and designers can help.

Design support is the very first step our engineers take to ensure you achieve the optimum results for your custom spring. Our team of technical design and manufacturing experts ensure the product lifetime of your spring functionality through our tested, recognised and reliable manufacturing processes, guaranteeing your custom spring products competitiveness and quality.

Our compression springs, tension springs and torsion springs are bespoke to you, custom made springs designed and manufactured to your specifications.

Specialised spring manufacturing, requires a specialist customer service team and this is why our customers are assigned account managers with extensive experience across multiple industry sectors.

We are dedicated to delivering engineering excellence with a quality personal service and want to ensure that your journey from enquiry through to coil spring manufacture to dispatch is simple, seamless and excels at securing the spring solution you require.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy-duty spring solutions.

All our customers have dedicated account managers that oversee every step of the commercial and production process. Our team become an extension of your team, proactively positioned to understand and secure your requirements, to fast-track any urgent projects and to listen to your business needs.

We continually invest in the best and can design, quote, manufacture and dispatch your product within industry leading turnaround times at competitive prices.

From one to one million springs and beyond, there are no limits to the volume of spring manufacturing we offer.

We can help improve your supply chain and gain efficiencies through volume manufacture by stocking and storing your spring products. To discuss further, please contact your account manager or get in touch at heavysprings@lesjoforsab.com.

Require a certain type of freight, need your product packaged a specific way? Let us know how you would like your product packaged and our dispatch team will handle the rest.

Any extra details in your initial enquiry are much appreciated. If you don’t know your exact spring specifications, we can arrange a free consultation with our technical team to discuss your project.

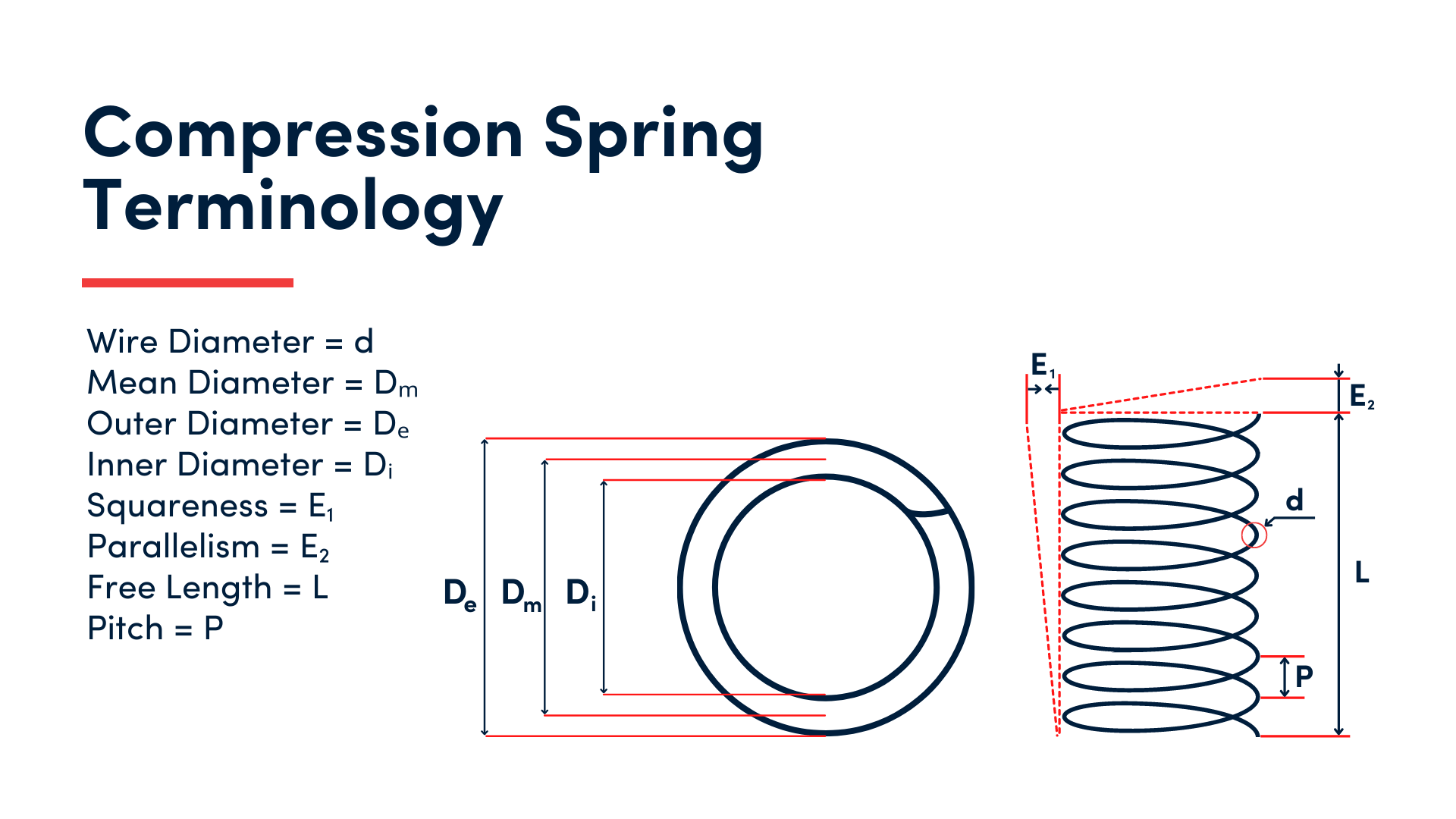

We have created a quick checklist to help you with your initial enquiry and please explore our spring terminology page which advises on common terms within the spring industry.

If you already have a CAD or other drawing of your required custom coil spring, please email it to heavysprings@lesjoforsab.com and upload your file as an attachment.

Design development and support is the very first step our engineers take to ensure you achieve the optimum results for your product.

If you would like a spring consultation please feel free to get in touch. Our spring design engineers are able to advise on every stage of your spring projects development.

On average 4-6 weeks but this can be affected by outside market factors affecting shipping and raw material access. We aim for 4-6 weeks.

Spring prototype development is key to a spring’s performance and success. Establishing the best engineering and material route for our customers’ metal springs delivers the quality we pride ourselves on and that our customers expect.

The most common metals used to make heavy duty springs include:

The expertise of our experienced engineers is unmatched and they are available to advise on all material decisions. As part of a global network of spring engineering material scientists, you can guarantee that your metal spring will perform at peak with the right material for the right function.

Lesjöfors Heavy Springs specialises in custom coil spring manufacturing. Our advanced spring manufacturing infrastructure features an extensive range of large-scale, high-end spring coiling machines across hot and cold coiling CNC machine technologies, manufacturing your quality springs to order.

Ongoing investment, backed by our parent company Lesjofors AB, enables us to not only continually invest in the best custom spring manufacturing processes but also ensures our competitiveness across the industry.

Using a caliper you will need to measure the following:

If you can, it would also be helpful to determine your coil spring wire type and material. You can also send a prototype spring to our engineers and they will be happy to do the calculations for you.

Yes! We specialise in this. Please visit our design and development page or get in touch via the contact us page.

Yes. Our powder coating facilities are constantly expanding their capabilities. We can print product batch numbers on each spring too.

3mm here but down to 0.03mm across the Lesjöfors Group – we’ll pass your enquiry on.

We manufacture low and high-volume production numbers.

We will work towards your project lead time and delivery preferences.

65mm wire diameter currently. However, we are always expanding our capabilities so please let us know what size you need and we’ll see if we can manufacture it for you.

Please visit our Frequently Asked Questions page for all your coil spring enquiries. Please don’t hesitate to get in touch if you have any other questions.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.