Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

We make springs for world-class construction equipment suppliers.

Construction projects commonly feature springs in the operational equipment, machinery and fixtures and fittings required to deliver the built environment.

Our springs not only feature in the power tools and heavy plant machinery required to build large construction projects but also sit within the structures themselves and you will find them across multiple buildings and bridges. Architectural icons such as the Tate Modern and The Shard, Jewel Changi airport in Singapore as well as the O2 arena, all feature our spring technology as part of these structures seismic protection and earthquake building management.

We continually invest in the best and can design, quote, manufacture and dispatch your product within industry leading turnaround times at competitive prices.

From one to one million springs and beyond, there are no limits to the volume of spring manufacturing we offer.

We can help improve your supply chain and gain efficiencies through volume manufacture by stocking and storing your spring products. To discuss further, please contact your account manager or get in touch at heavysprings@lesjoforsab.com.

Require a certain type of freight, need your product packaged a specific way? Let us know how you would like your product packaged and our dispatch team will handle the rest.

Changing climatic environments and conditions impact on construction projects and our spring design and manufacturing processes reflect the needs of high durability requirements. Our technical engineers assess the stress, temperature and corrosive risks a product endures to ensure durability is optimised for the right application.

We’re trusted by leaders within the construction industry.

Choice of spring material is entirely governed by the application and function that the spring requires. One of the most popular spring materials, due to its outstanding performance levels and exceptional strength is chrome silicon steel - a highly desired material in our construction work, alongside chrome vanadium wire.

Consequently, we hold one of the largest global stocks of chrome silicon and chrome vanadium wire anywhere in the world

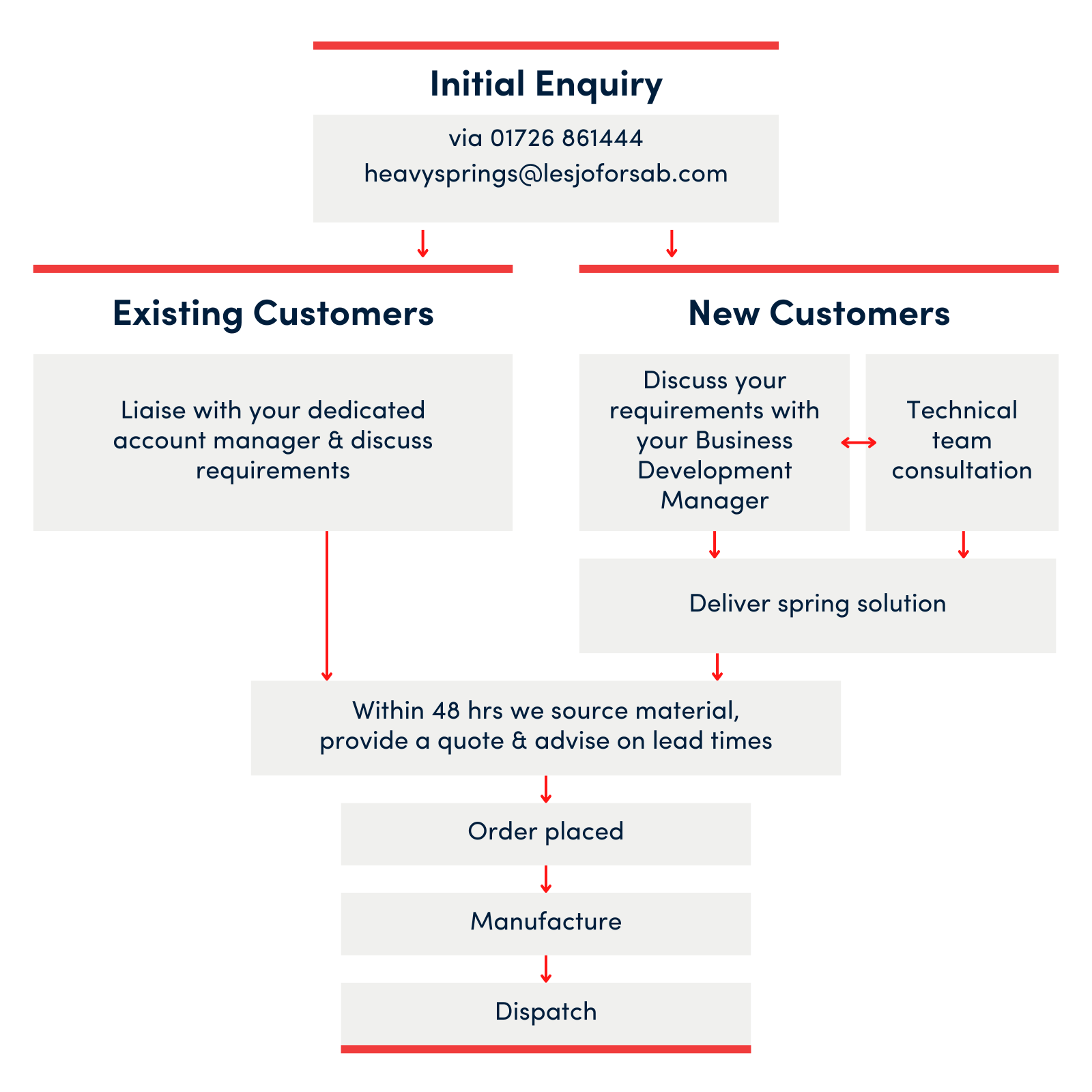

We are dedicated to delivering engineering excellence with a quality personal service and want to ensure that your journey from enquiry through to coil spring manufacture to dispatch is simple, seamless and excels at securing the spring solution you require.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy-duty spring solutions.

All our customers have dedicated account managers that oversee every step of the commercial and production process. Our team become an extension of your team, proactively positioned to understand and secure your requirements, to fast-track any urgent projects and to listen to your business needs.

Compression springs, tension springs and torsion springs are common spring types used within construction applications. Varying spring designs, size and type play an essential component role in heavy plant equipment, in the tools used to build structures, in vibration isolation and across a building’s mechanical equipment; including garage doors, HVAC systems, blinds and elevator systems and escalator functions.

As energy efficiency, sustainability and natural power generation becomes increasingly important we’re seeing springs utilised across a number of buildings that harvest energy from their surroundings.

The building, repair, renovation and maintenance of cities, towns, industrial sites and communities relies on world-class engineers and we match the built environments quality expectations with advanced production technology and leading expertise. Our technical, quality, engineering and production teams enjoy partnerships with a host of construction suppliers including plant machinery manufacturers and building equipment suppliers, right through to architectural firms and fitting suppliers.

All our projects start with consultations; establishing drawings to meet precise specifications and designing prototypes that evolve as the product design process evolves. Performance handling assessments, technical reviews, safety testing and failure analyses collaborate to direct the demands of the precision spring and secure the right custom springs for construction application performances. Manufacturing and consistently testing samples before full production runs, is all part of the product service and customer culture we believe in to achieve product optimisation for our customers.

Our state-of-the-art facilities and teams of world-class experts, consistently challenge the science and engineering behind springs, shaping innovations in spring advancements.

Springs in construction are used for noise reduction, cushioning and shock absorption, for heavy equipment and machinery, they deliver energy storage for power-efficient solutions, offer flexibility and durability in large-scale structures and precision motion control for machinery and robotics.

It’s imperative that our bespoke spring design service offers customisation, innovation and adaptability for the transformational construction industry and that is why we secure spring solutions to fit construction needs specifics.

Limitations come down to the application requirements of the spring, material choice and tolerances. Our engineers are the best in their field at optimising the potential out of spring designs.

Once the design and manufacturing process is approved, we can produce your construction springs when you need them. Our OTD is exceptional.

Absolutely. We welcome knowledge sharing and our engineers are always on hand to consult and support.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.