Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

Our advanced Torsion Spring Manufacturing infrastructure uniquely offers hot and cold coiling torsion spring facilities, establishing Lesjöfors Heavy Springs as the custom heavy duty torsion spring specialists.

Bespoke designed and manufactured to meet the needs of our customers, the ends of each torsion spring can be tailored to suit the application required.

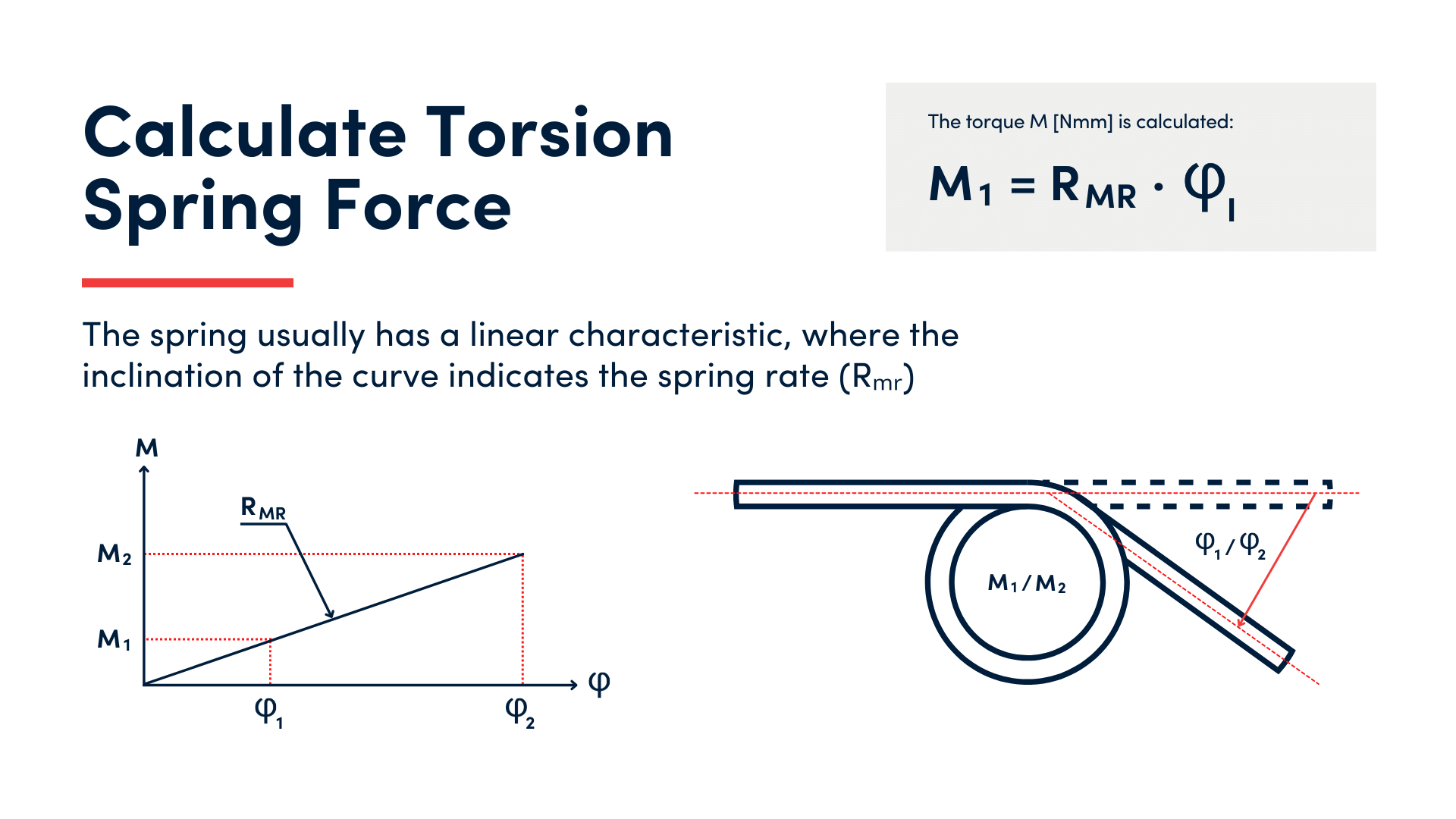

Manufactured from larger wire sizes, our torsion springs can exert an exceptionally large amount of torque (due to the size of the wire) when a load/pressure is placed on the legs of the torsion spring.

The ends (or legs) of a torsional spring are attached to other components within an application and when these components rotate, the centre of the spring stores the mechanical energy and forces the components back.

Torsion springs are coiled springs that are designed to have a rotational motion that exerts a torque or force.

The most common spring type when torque is required alongside a rotating movement, torsion springs must always be loaded in the direction of the spring wire, so that the spring body closes.

Most applications need a right-hand wound torsion spring mounted on one side and a left one on the other. However, in some cases, these two springs can be combined into a double torsion spring, which has one right and one left-hand coiled spring body connected to each other.

Due to the nature of the torsion spring design, they can be used across applications that work either through a clockwise or counter-clockwise motion.

As the expert heavy duty torsion spring suppliers, our teams bespoke engineer the torque to fit the application required.

Find more about spring terminology.

Our torsion springs are designed to deliver exceptional performance and durability, making them the premium choice for heavy-duty applications.

Allocated team of experts ensuring that the final product meets all requirements and specifications.

Creating a precision spring solution that enables you to test the requirements of your product before going into full production.

Stainless steel torsion springs are one of our most common torsion spring material requests from customers.

Our material scientists are on hand to discuss the environmental need and application of your coil spring and therefore the torsion spring material's disadvantages and advantages.

A very high yield type of material (able to withstand high amounts of stress and maximum load) is best suited for torsion springs and as stockists of the largest global supply of chrome silicon wire, we’re confident in our supply and range of material choices suited to your torsion spring material.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy duty spring solutions.

Lesjöfors Heavy Springs offers a consultancy service. Our teams are available to discuss any engineering and technical issues regarding heavy spring specifications. Explore our Heavy Duty Extension Spring and Compression Spring pages.

The lead time for our torsion springs varies depending on the complexity of the design and the quantity required. We strive to deliver orders within the agreed-upon timeframe.

Yes, we can provide samples of our torsion springs for testing and evaluation. Contact us to discuss your sample requirements.

Feel free to reach out to us.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.