Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

We are experts in heavy-duty Extension Spring Manufacturing. We design, engineer and manufacture millions every year for custom specifications.

As expert heavy duty extension spring manufacturers, our springs operate throughout a whole host of heavy extension spring applications across multiple industries including construction, robotics, lifting equipment, agriculture, elevators and heavy plant machinery as well as speciality equipment.

Our teams are expert extension spring manufacturers offering hot coiling and cold coiling manufacturing capabilities across some of the most advanced spring technologies in the industry.

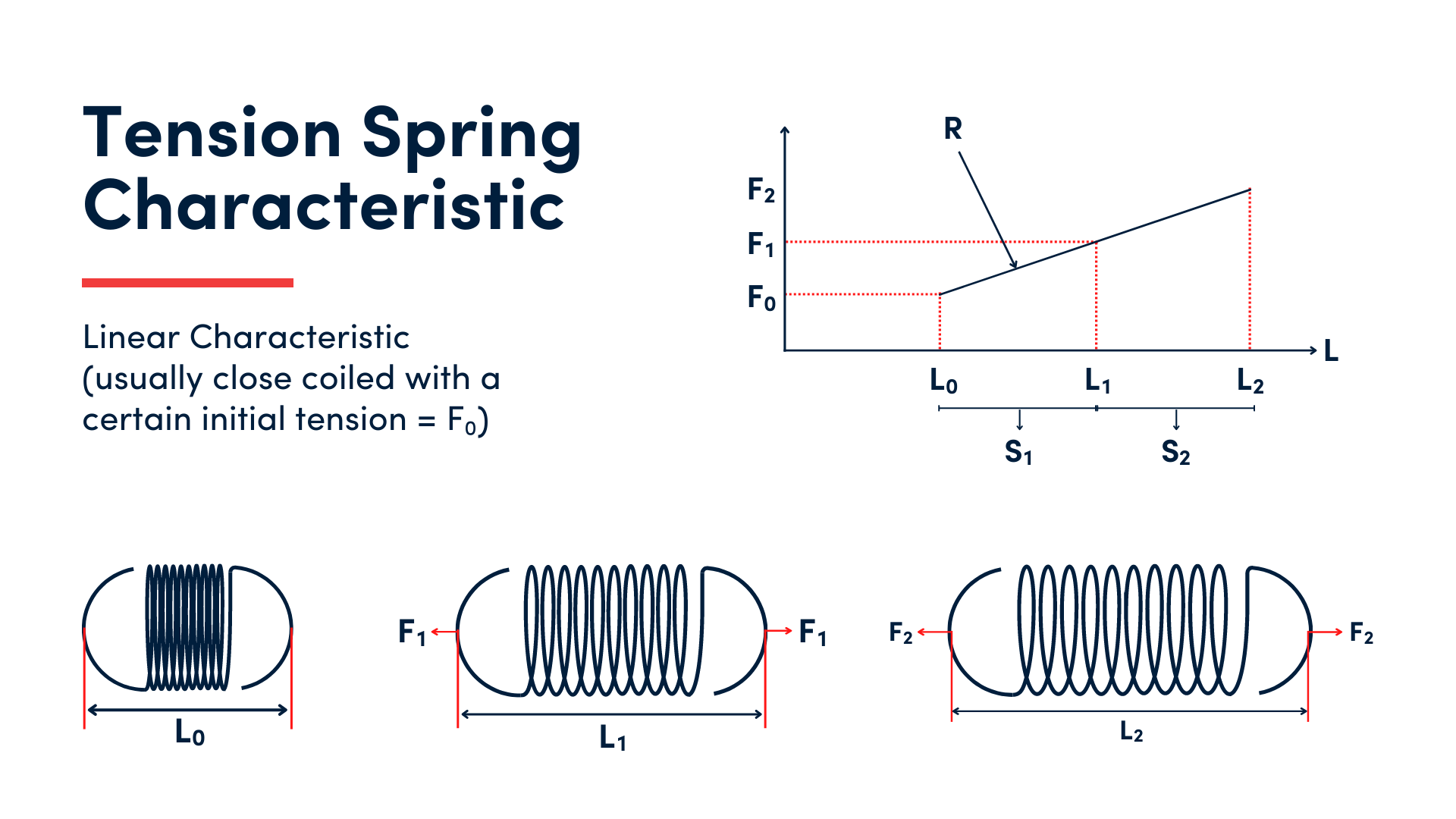

Heavy duty extension springs are tightly wound coils that allow for an outside force to create tension through an end fitting or loop, using this energy to pull components back together when reverting back to their original extension spring shape.

Our division specialises in the heavy extension spring which is the largest of the extension spring range.

As heavy duty, custom extension springs suppliers we design and manufacture heavy duty extension springs UK wide and across the globe for a wide variety of diverse industries and applications.

Extension or tension springs are similar to compression springs but with one distinct difference, the load direction is reversed – a tension (pulling) force, instead of a compression (pushing) force, causes the deflection via an end fitting.

The extension spring works as a link or an attachment between two components, drawing them together when another force separates them. An extension spring, for example, would be used on a trampoline to secure the matt to the frame but more significantly provide the energy required through its tension to give the trampoline its bounce. A high rated extension spring would give additional energy and bounce compared to a lower rated extension spring.

Find more about spring terminology.

Read how extension springs work

Read how extension springs work

Read more on types of extension springs

Read more on types of extension springs

Our extension springs are designed to deliver exceptional strength, performance and durability, making them the premium choice for heavy-duty applications.

Allocated team of experts ensuring that the final product meets all requirements, offering custom capabilities tailored to your needs.

Creating a precision spring solution that enables you to test the requirements of your product before going into full production.

We hold the largest stock of chrome silicon in the world and work with carbon steels, low and high alloyed steels which enables our engineers to source the right material for the right application and work environment of your extension spring.

When considering industrial extension springs, our engineering teams evaluate the extension spring material types for chemical composition, surface properties, tensile strength and wire diameter.

Our material scientists are leaders in their field and are on hand to consult with our engineers on the properties of all our metals.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy duty spring solutions.

Lesjöfors Heavy Springs offers a consultancy service. Our teams are available to discuss any engineering and technical issues regarding heavy spring specifications. Explore our Heavy Duty Compression Spring and Torsion Spring pages.

An extension spring is designed to absorb and store energy by resisting a pulling force. Its primary purpose is to return to its original length when the force causing the extension is removed.

Extension springs offer several advantages, including the ability to absorb and store significant energy, making them ideal for applications requiring controlled tension and resistance. They are versatile and customisable in terms of length, diameter, and material, ensuring optimal performance for specific needs.

Extension springs are manufactured from a variety of materials to meet different application needs. High-carbon steel is commonly used for its strength and durability in general applications. Stainless steel provides excellent corrosion resistance, making it suitable for environments exposed to moisture. Phosphor bronze offers good corrosion resistance and electrical conductivity, ideal for specific industrial and electrical uses. Nickel alloys, such as Inconel, are chosen for their high-temperature resistance and strength in extreme conditions. Additionally, music wire, a type of high-carbon steel wire, is favoured for its high tensile strength and durability in demanding applications.

The lead time for our extension springs varies depending on the complexity of the design and the quantity required. We strive to deliver orders within the agreed-upon timeframe.

Yes, we can provide samples of our extension springs for testing and evaluation. Contact us to discuss your sample requirements.

Extension springs are sized by wire diameter, outside diameter, body length, overall length including hooks, and spring rate. You may want to learn more about how to measure an extension spring.

Feel free to reach out to us.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.