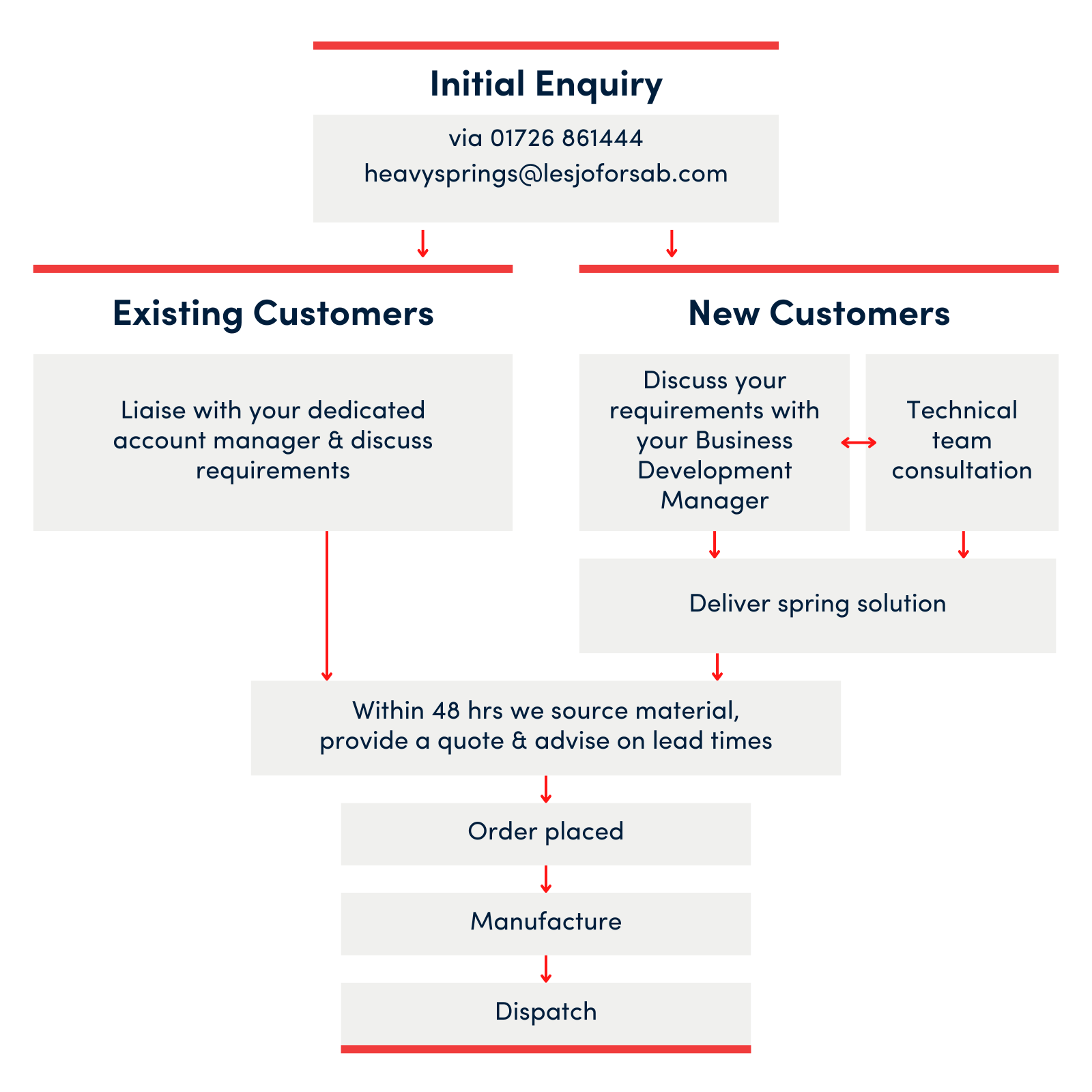

Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

Innovation is key to robotics and we’re proud to partner with leaders in the field, providing our own innovative spring solutions for robotics.

Springs are integral components in the robotics industry, providing solutions across compliance, energy storage and force control, contributing to, and enhancing, the functionality and performance of robotic systems.

Our own manufacturing facilities have a suite of robotics, improving costs, time and safety in the workplace.

Knowing what we need out of the robotic facilities we have, as well as being experts in heavy duty robotic springs, makes us best placed to be industrial robotic spring manufacturers producing custom robotic springs for the rapidly evolving robotics industry.

We continually invest in the best and can design, quote, manufacture and dispatch your product within industry leading turnaround times at competitive prices.

From one to one million springs and beyond, there are no limits to the volume of spring manufacturing we offer.

We can help improve your supply chain and gain efficiencies through volume manufacture by stocking and storing your spring products. To discuss further, please contact your account manager or get in touch at heavysprings@lesjoforsab.com.

Require a certain type of freight, need your product packaged a specific way? Let us know how you would like your product packaged and our dispatch team will handle the rest.

Spring engineering design is often led by force specification which is vital for precision performance, durability and reliability.

We know springs, we know spring materials and our unique global design, manufacturing and technological development network is dedicated to service, quality and accuracy, coiling wire from 3mm to 65mm in diameter.

Through a consultative process with our engineers, we are able to calculate the spring specification for your product. Our dedicated teams of design engineers are the experts to advise on spring design.

The quality, accuracy and performance delivered through our progressive spring designs and manufacture is exceptional. Maximising the potential of a robotic spring by delivering exceptional design, development and manufacturing is a key part of the performance success of our springs and guarantees the competitiveness and quality of your product.

The repetitiveness of the work function of a spring is key to understanding the performance demands on that spring. It is also the launch point for our engineers and material scientists to develop a spring product that secures a lifespan that excels.

The most distinguishing property of a coil spring's material is its mechanical strength and elasticity. The four key components when considering material choice are chemical composition, surface property, tensile strength and size. These essential elements build the structure from which our engineers custom robotic springs, to meet the demands of the application of springs within the robotics sector and to optimise the purpose and power.

Our state-of-the-art spring manufacturing technologies, across the very latest and widest range of large-scale CNC spring coiling machines, coupled with the most advanced spring manufacturing processes and expert engineers, provides the highest quality precision springs for robots.

We are dedicated to delivering engineering excellence with a quality personal service and want to ensure that your journey from enquiry through to coil spring manufacture to dispatch is simple, seamless and excels at securing the spring solution you require.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy-duty spring solutions.

All our customers have dedicated account managers that oversee every step of the commercial and production process. Our team become an extension of your team, proactively positioned to understand and secure your requirements, to fast-track any urgent projects and to listen to your business needs.

Our teams of spring engineers have secured us as a leading robotics industry spring supplier due to their work and advances in research and development, aligning and synergising skills, materials and technology alongside the demands of the ever-evolving robotic industry.

We have worked alongside and provided robotic springs to experts in the robotic manufacturer field for many years, continually enhancing our expertise and advancing spring development in the robotics sector.

With decades of experience providing precision springs for robots, our robot component springs have been used across every aspect from robotic arms to robotic grippers and robotic joints to robotic assembly and testing systems to suspension and vibration dampening systems.

Our springs are utilised in robotics across multiple industries and are crucial component factors, playing an essential role in functionality and performance, in a wide range of robotic applications.

Springs allow robots to absorb and adapt to external forces. This is especially important in situations where the robot interacts with its environment or human users. Springs help in making robotic movements more flexible and responsive.

Springs store and release energy efficiently. In robotics, this feature is utilised in applications where sudden bursts of energy or controlled movements are required. For example, springs are used in robotic limbs to store energy during a movement and release it to enhance the speed and efficiency of the motion.

Springs are often integrated into force sensors to measure and control the force exerted by a robot. This is crucial for applications such as robotic grippers, where precise force control is necessary to handle delicate objects without causing damage.

In mobile robotics or robotic vehicles, springs are employed in suspension systems to absorb shocks and vibrations. This helps in maintaining stability and enhances the overall performance of the robot, especially in uneven terrains.

Springs can also be used to create compliant joints in robotic arms or legs. This compliance allows for safer interactions with humans and delicate objects, as the robot can adjust its movements based on external forces.

Springs contribute to the balance and stability of robotic systems. By incorporating springs strategically, engineers can design robots that are more resistant to external disturbances, improving their overall reliability.

Springs come in various sizes and materials, allowing for the miniaturisation of robotic components. This is beneficial in creating compact and lightweight robotic systems, essential for applications such as drones and medical robots

To discover the Lesjofors Group’s work with miniature springs for robots, please visit www.lesjoforsab.com

We have worked closely with robotic manufacturers for decades. Load and force requirements, temperature and pressure resistance, fatigue resistance, material selection and energy storing capabilities are essential discussion areas which lead into the right compression, extension or torsion spring manufacture.

All our projects start with consultations; establishing drawings to meet precise specifications and designing prototypes that evolve as the product design process evolves.

We know springs, we know their applications across the robotics landscape - we use robotic equipment ourselves to enhance the efficiency of our production processes and capabilities.

Performance handling assessments, technical reviews, safety testing and failure analyses collaborate to direct the demands of the precision spring and secure the right custom springs for robotic application performances.

Material and where it is sourced matters. High strength alloys are the premier choice for high performance springs as they deliver incredible durability, strength and weight to performance ratios.

Extremely resistant to corrosion, pressure and high temperatures, super alloy springs deliver advanced performance properties. Alongside our chrome alloys, we also use Nickel, Cobalt and Titanium materials. We also request that our material suppliers determine the source of specified minerals to ensure they do not come from conflict areas.

An essential part of the manufacturing process, heat treatment removes residual stress introduced to the material during the coiling process. The treatment stabilises the springs dimensions for greater accuracy and increased fatigue life and our oven facilities use forced convection technology to ensure the material is uniformly heat treated from surface to core. Our larger transport industry springs (such as for locomotive suspension springs), using a wider wire diameter, require a hot winding process as the extreme heat allows large scale wire diameters to be coiled.

The process of heating up wire to approximately 900 degrees celsius, quenching in oil and tempered to complete the heat treatment, allows the spring material to be coiled to the specifications required.

The future of the robotics industry is marked by several transformative trends that are expected to shape the landscape. We know that it is essential that we learn as the increased integration of AI learns.

Cobots, 5G and connectivity and human augmentation are robotic elements that will increasingly influence change and, as we partner with providers of this technology, we are ensuring that our state-of-the-art facilities, skills and innovations match future demands, to secure us as one of the leading robotics industry spring suppliers for heavy duty robotics.

There are many spring types and the most common is compression springs for robotics. Torsion springs for robots and extension springs for robotic applications are numerous and each design is individual to the need of the customer and the requirement of the application.

Limitations come down to the application requirements of the spring, material choice and tolerances. Our engineers are the best at optimising the potential out of spring designs.

Once the design and manufacturing process is approved, we can produce your springs when you need them. Our OTD is exceptional.

Absolutely. We welcome knowledge sharing and our engineers are always on hand to consult and support.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.