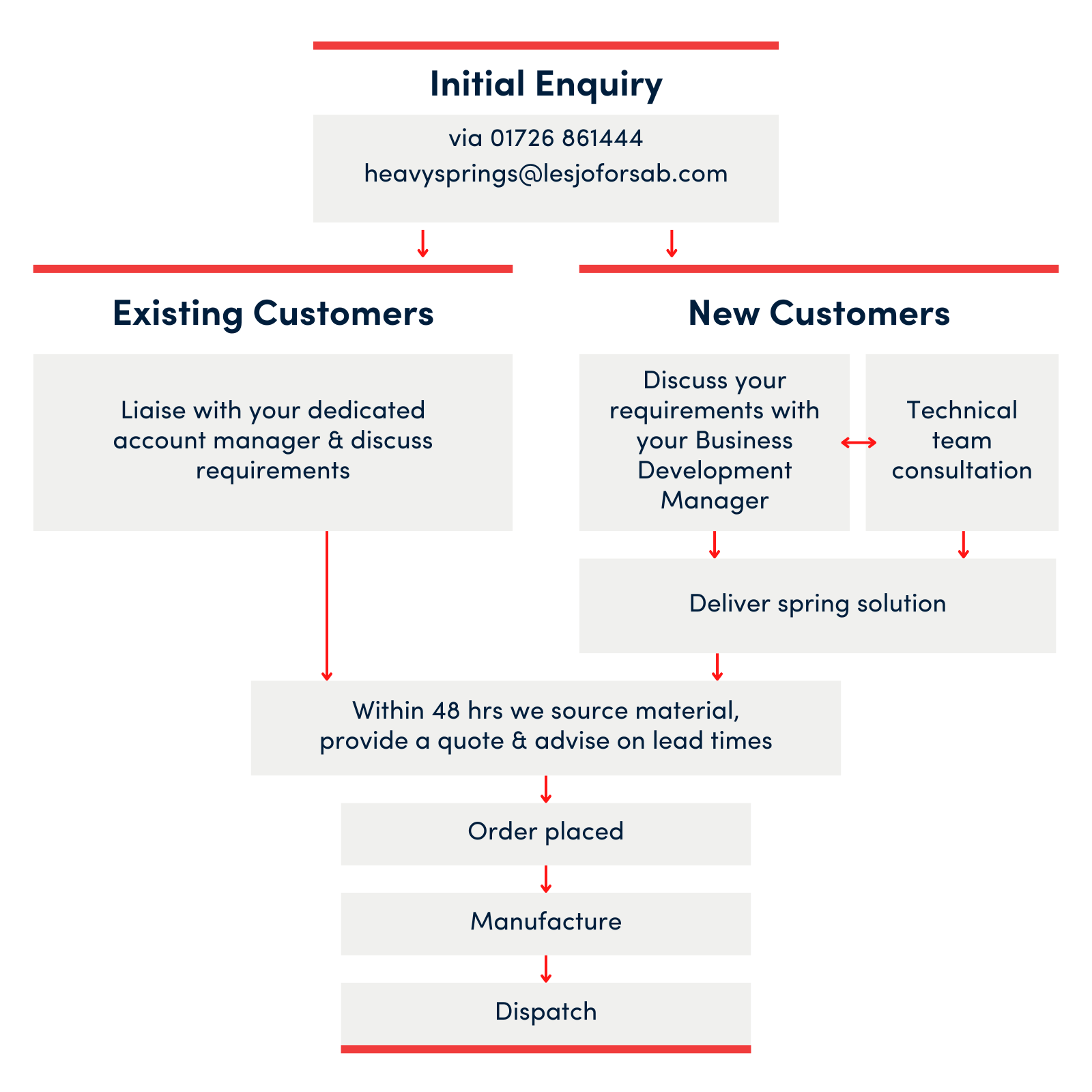

Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

The rail industry is one of the oldest forms of transport and our springs have played a crucial role in ensuring the proper functioning and safety of various spring components for trains for hundreds of years.

Train suspension technology requires springs to absorb shock and vibration, to distribute loads and to stabilise the rail system, delivering a smooth and efficient operation. With spring manufacturing for railways starting in our formative years in 1852, we have been at the forefront of innovation and manufacture for the rail industry’s springs for decades.

We continually invest in the best and can design, quote, manufacture and dispatch your product within industry leading turnaround times at competitive prices.

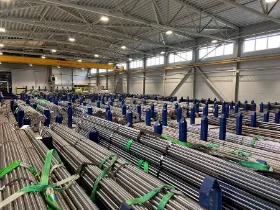

From one to one million springs and beyond, there are no limits to the volume of spring manufacturing we offer.

We can help improve your supply chain and gain efficiencies through volume manufacture by stocking and storing your spring products. To discuss further, please contact your account manager or get in touch at heavysprings@lesjoforsab.com.

Require a certain type of freight, need your product packaged a specific way? Let us know how you would like your product packaged and our dispatch team will handle the rest.

Spring design for rolling stock starts with consultations; establishing drawings to meet precise specifications and designing prototypes and samples that evolve as the product design process evolves. Railcar performance handling assessments, technical reviews, safety testing and failure analyses collaborate to direct the demands of the precision spring and secure innovation in rail spring design to achieve the peak performance befitting the trains functionality and environment.

Maximising the potential of a spring by delivering exceptional design, development and manufacturing production processes is a key part of our customer experience methodology. It is also the winning performance formula behind a rail spring component’s success. Our audited, tested, recognised and reliable multi-stage manufacturing process guarantees the competitiveness and quality of your product.

We are dedicated to delivering engineering excellence with a quality personal service and want to ensure that your journey from enquiry through to coil spring manufacture to dispatch is simple, seamless and excels at securing the spring solution you require.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy-duty spring solutions.

All our customers have dedicated account managers that oversee every step of the commercial and production process. Our team become an extension of your team, proactively positioned to understand and secure your requirements, to fast-track any urgent projects and to listen to your business needs.

Delivering high-speed rail spring solutions across passenger train spring systems to freight car springs, heavy-duty rail springs play a vital role across many applications.

Springs are integral components of a railway vehicle suspension system. They absorb shocks and vibrations, provide a smoother ride for passengers and protect the train's structure from excessive wear and tear.

Coil spring technology is used in buffers and couplings between railcars as the railroad springs manage the impact and forces during coupling and decoupling operations, preventing damage to the rolling stock.

Springs assist in distributing the weight of the train evenly, especially in cases of uneven loading or on uneven tracks. This is crucial for maintaining stability and preventing derailments.

Tension springs and compression springs are also commonly used in the door mechanisms of trains. They assist in the smooth opening and closing of doors, contributing to passenger safety and comfort.

Compression springs are a crucial part of braking systems in trains. They contribute to the efficient operation of brakes, helping to control the speed of the train and ensuring safety during stops.

Springs are employed in various components to absorb shocks and vibrations generated during train movement. This not only enhances passenger comfort but also protects the train's equipment and structure.

Spring maintenance for trains is essential, contributing to the overall reliability of rail systems. Regular inspections and replacements of worn-out springs are essential to prevent failures and disruptions in rail operations.

Springs are employed in rail joints and fasteners to reduce vibration noise and to maintain the necessary tension and ensure a secure connection between rail segments. This helps in preventing track misalignment and ensuring a stable track structure.

Matching our customers world-class performance expectations with advanced production technology and leading expertise, our technical, quality, engineering and production teams enjoy partnerships with leading rail industry suppliers and with OEM’s.

The majority of our projects involve spring customisation for the rail industry with the design, development, innovation and manufacture of locomotive suspension springs shared through the expertise of our hot coiling and cold coiling spring teams in the UK, Sweden & Finland.

An essential part of the manufacturing process, heat treatment removes residual stress introduced to the material during the coiling process. The treatment stabilises the springs dimensions for greater accuracy and increased fatigue life and our oven facilities use forced convection technology to ensure the material is uniformly heat treated from surface to core. Our larger transport industry springs (such as for locomotive suspension springs), using a wider wire diameter, require a hot winding process as the extreme heat allows large scale wire diameters to be coiled.

The process of heating up wire to approximately 900 degrees celsius, quenching in oil and tempered to complete the heat treatment, allows the spring material to be coiled to the specifications required.

We are very fortunate to work with exceptional partners within the rail industry, to further our R&D through integrated relationships with them and in turn be at the leading edge of train suspension technology and systems.

Our exceptional expertise and spring testing in rail applications, across our advanced technologies, material scientists, stocks, insights and research facilities enable us to consistently explore advancements in our rail industry spring products.

From lightweight materials, efficient energy recovery systems, braking systems and noise reduction, we are working on a number of projects that explore all these factors. We will continue to develop these areas further to guarantee our position as the best solution for our customer’s rail transport spring needs.

Limitations come down to the application requirements of the spring, material choice and tolerances. Our engineers are the best at optimising the potential out of spring designs.

Once the design and manufacturing process is approved, we can produce your springs when you need them. Our OTD is exceptional.

Absolutely. We welcome knowledge sharing and our engineers are always on hand to consult and support.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.