Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

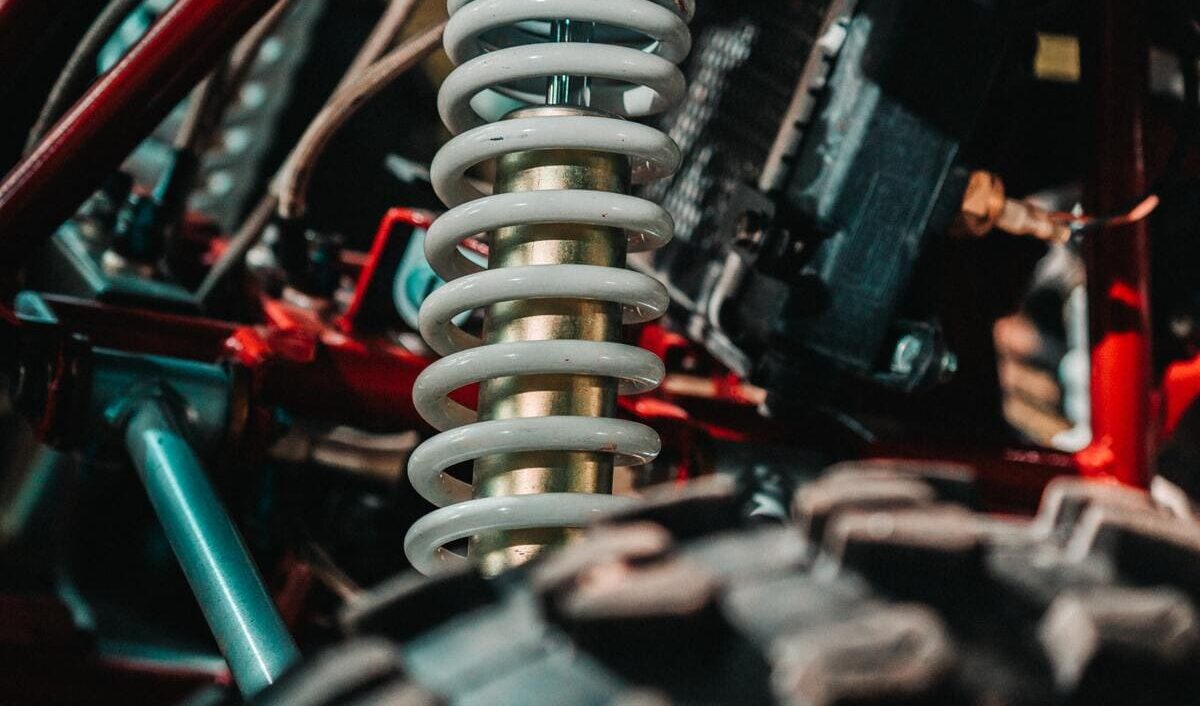

Our prototype development service enables us to create a precision spring solution that enables you to test the requirements of your product before going into full production.

Allocated Team of Experts

Our technical teams will analyse a spring’s requirements, identify potential challenges, develop drawings, develop prototypes and then manufacture small batch samples for performance and functionality testing.

Designing Prototypes

Designing prototypes that evolve as your product design evolves and manufacturing samples before full production runs, is all part of the customer care and product service culture we believe in - helping to minimise errors, reduce costs, and ultimately deliver superior results.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, our team are the experts at spring solutions.

Spring product design is at its most successful when we work with our customers. Having worked with industry leaders across every sector, we are uniquely positioned to understand the needs of every industry.

With access to one of the largest global stocks of chrome silicon and chrome vanadium wire, we're well-equipped to handle projects of any scale or complexity.

This breadth of material expertise allows us to tailor solutions precisely to the requirements of each application, ensuring optimal performance and reliability for every customer's product.

At the onset of each new spring development project, thorough exploration of the technical requirements is paramount to ensure optimal design and performance. This investigation dives into various aspects of the spring's application to gain a comprehensive understanding of the project's needs.

This comprehensive review process, including meticulous attention to detail at every step, reinforces our commitment to delivering high-quality springs recognised in our ISO 9001, 14001 and 45001 certifications.

Drawing Review: Ensuring that the drawings are not only appropriate for the spring's intended application but also correct for production, guaranteeing alignment between design and manufacturing.

Testing Procedures: Thoroughly reviewing the testing procedures to validate the spring's performance and durability, ensuring it meets or exceeds specified requirements.

Powder Coating Inspection: Verify that the powder coating meets the desired finish and density specifications, contributing to the spring's aesthetic appeal and functional performance.

Print Markings Confirmation: Confirming that print markings are accurate and legible

Almen Arc Test: Conducting the Almen Arc test to assess the shot peening process effectiveness, ensuring that the intensity of the shot is precisely calibrated to meet the material's requirements, thus enhancing its strength and longevity.

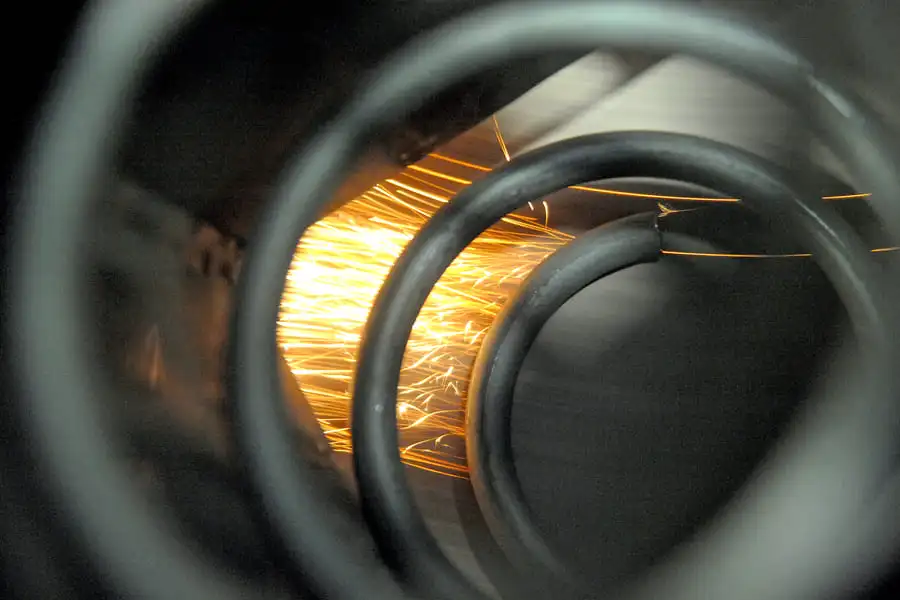

We specialise in custom heavy coil spring manufacturing. Our advanced spring manufacturing infrastructure features an extensive range of large-scale, high-end spring coiling machines across hot and cold coiling CNC machine technologies, manufacturing your quality springs to order.

Extensive Capabilities

Our extensive capabilities guarantee precision, accuracy, and reliability while maintaining peak operational efficiency.

End-to-End Service

It's this end-to-end service that enables us to manage every aspect of the manufacturing process, from concept to completion.

Discover cutting-edge technologies and advancements in spring prototyping that are shaping the future of the industry. Our team of experts are dedicated to delivering innovative solutions that meet your unique needs.

Our prototype development service enables us to create a precision spring solution that enables you to test the requirements of your product before going into production.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.