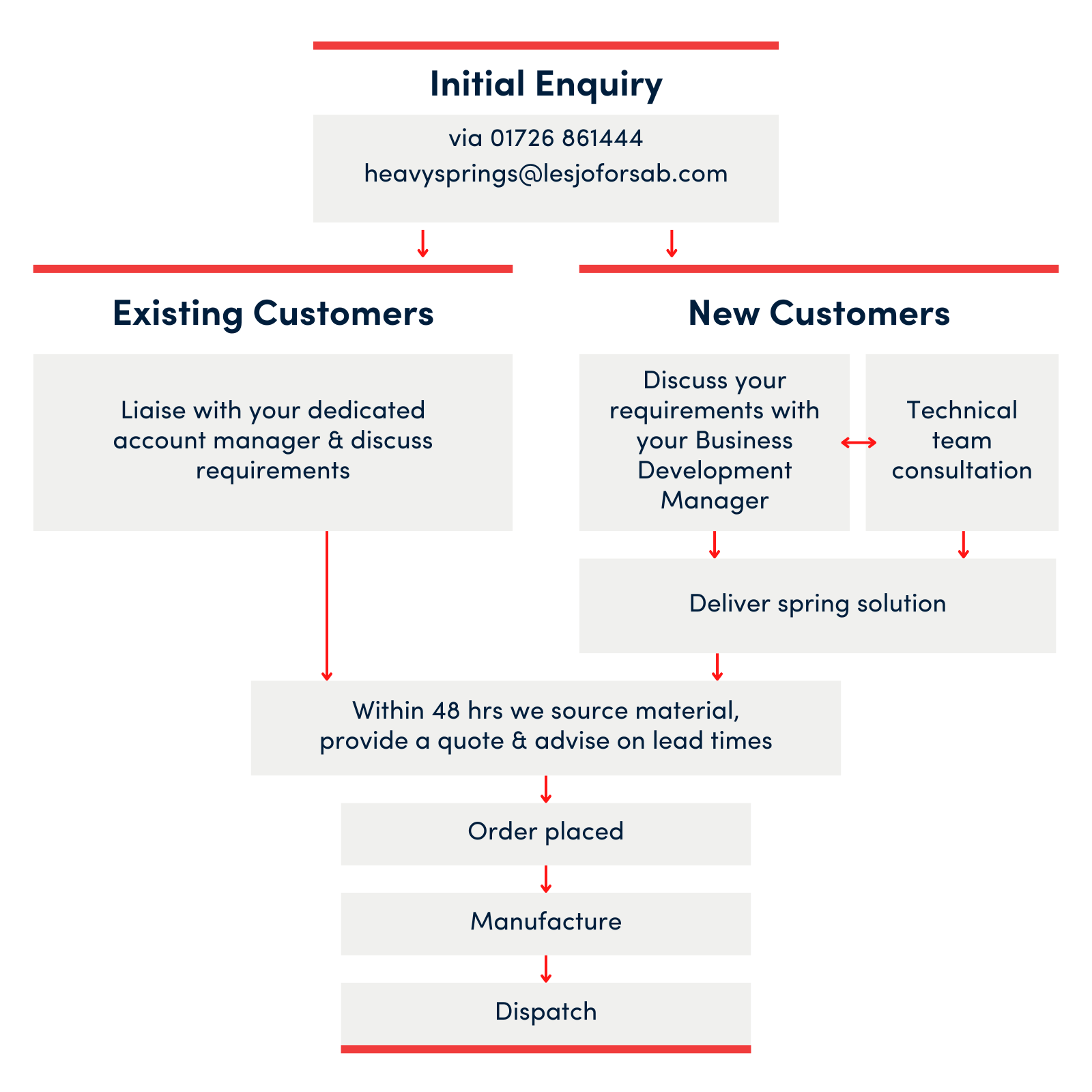

Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

We proudly develop and manufacture precision race suspension springs for many of motorsports' most trusted brands.

Springs are a critical component of motorsport racing suspension systems and motorsport disciplines use high-performance springs to deliver superior suspension.

Our high-quality, precision engineered and manufactured high-performance race suspension springs deliver a significant competitive advantage, securing championship-winning success.

We continually invest in the best and can design, quote, manufacture and dispatch your product within industry leading turnaround times at competitive prices.

From one to one million springs and beyond, there are no limits to the volume of spring manufacturing we offer.

We can help improve your supply chain and gain efficiencies through volume manufacture by stocking and storing your spring products. To discuss further, please contact your account manager or get in touch at heavysprings@lesjoforsab.com.

Require a certain type of freight, need your product packaged a specific way? Let us know how you would like your product packaged and our dispatch team will handle the rest.

Spring design leads product optimisation; achieving cutting-edge bespoke solutions to weight, height, stability, durability, fitment and performance.

From compression springs for adjustable coil overs to progressive and dual rate compression springs for F1 through to offroad racing, we understand the technicalities behind the demands of motorsport suspension.

Our teams are the precision experts and are always on hand to discuss your motorsport spring applications and assist in design optimisation and material advancements.

For motorsports springs, material matters. High strength alloys are the premier choice for race suspension springs as they deliver incredible durability, strength and weight to performance ratios. Extremely resistant to corrosion, pressure and high temperatures, super alloy springs deliver advanced performance properties. Alongside our chrome alloys, we also use Nickel, Cobalt and Titanium materials to deliver high performance springs.

We are dedicated to delivering engineering excellence with a quality personal service and want to ensure that your journey from enquiry through to coil spring manufacture to dispatch is simple, seamless and excels at securing the spring solution you require.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy-duty spring solutions.

All our customers have dedicated account managers that oversee every step of the commercial and production process. Our team become an extension of your team, proactively positioned to understand and secure your requirements, to fast-track any urgent projects and to listen to your business needs.

With a legacy of supplying motorsport race teams with precision coil springs, we know the variety of extreme racing requirements faced by our products. From the Dakar Rally, Indianapolis 500 to the Isle of Man TT, Formula racing and the Goodwood Festival of Speed every event has differing coil spring needs. Continual R&D, project analysis, feedback and investment across our technologies and our teams, position us at the forefront of motorsport spring manufacturing.

We work with world-class racing car parts manufacturers who are at the forefront of R&D in motorsport innovation and race suspension products in competitive racing.

Matching our customers' world-class performance expectations with advanced production technology and leading expertise, our technical, quality, engineering and production teams enjoy partnerships with OEMs and aftermarket coil spring suppliers.

The majority of our motorsport engineering projects are designing, developing and manufacturing custom suspension for motorcycle racing springs and race car suspension springs.

High-performance race suspension products start with consultations; establishing drawings to meet precise specifications and designing prototypes and samples that evolve as the product design process evolves. Vehicle performance handling assessments, technical reviews, safety testing and failure analyses collaborate to direct the demands of the precision suspension spring and secure the right bespoke coil spring performance for the racing environment.

Manufacturing and consistently testing samples before full production runs is all part of the product service and customer culture we believe in to achieve the win for our race suspension customers.

Coil springs for motorsports are peak performance projects – targeted at gaining the most out of the spring, delivering optimum results and reliability within its required design during its defined life.

To gain the maximum potential out of a race suspension spring, the coil spring needs to be as light and as strong as possible.

Identifying the perfect design, material, manufacturing process and finish of the compression coil spring type lies within our technical engineering and quality teams who know how far to push the design and chosen materials capabilities.

Years of development, research and numerous testing procedures allow for the scrutinising of acquired data by our quality teams - who have all the systems in place to deliver the safety net which allows the race suspension coil spring to push the boundaries of design to achieve maximum results and balance the requirement between performance and fatigue life.

Our team of world-class experts and state-of-the-art facilities consistently challenge the science and engineering behind springs, shaping innovations in spring advancements.

We are developing customised solutions with evolving new smart technology and precision engineering techniques using advanced materials to enable increasingly lightweight race spring solutions with increased durability.

With a wealth of advanced materials in our stores and material scientists who continually advise on the properties and parameters of these materials, our quality spring designs are leading high-performance vehicle suspension advancements.

Additionally, a number of ongoing investments enhancing our sustainable manufacturing practices with digitisation, new technology streamlining operations and exploring low carbon metals aims to offer a more sustainable spring solution for tomorrow’s motorsport industry.

Yes. Each race suspension spring project is bespoke and unique to the customer.

Our powder coating facilities can custom paint race team and brand colours and we’re investing in new technologies allowing for corporate logo printing on our spring products.

Once the design and manufacturing process is approved, we can produce your motorsport springs when you need them. Our OTD is exceptional.

It is essential that the race spring delivers as expected. Testing the stress on a spring is a key part of the spring manufacturing process to ensure the spring design, material and method of manufacture is fit for purpose. Our fully computerised, calibrated and regularly reviewed spring load testing units can accurately correlate design with performance required.

We also feature a bespoke designed, fully automated pre-stress machine for large volume batch testing.

The expertise of our technical engineers on our spring products is second to none and they’re on hand to consult and advise on all spring projects

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.