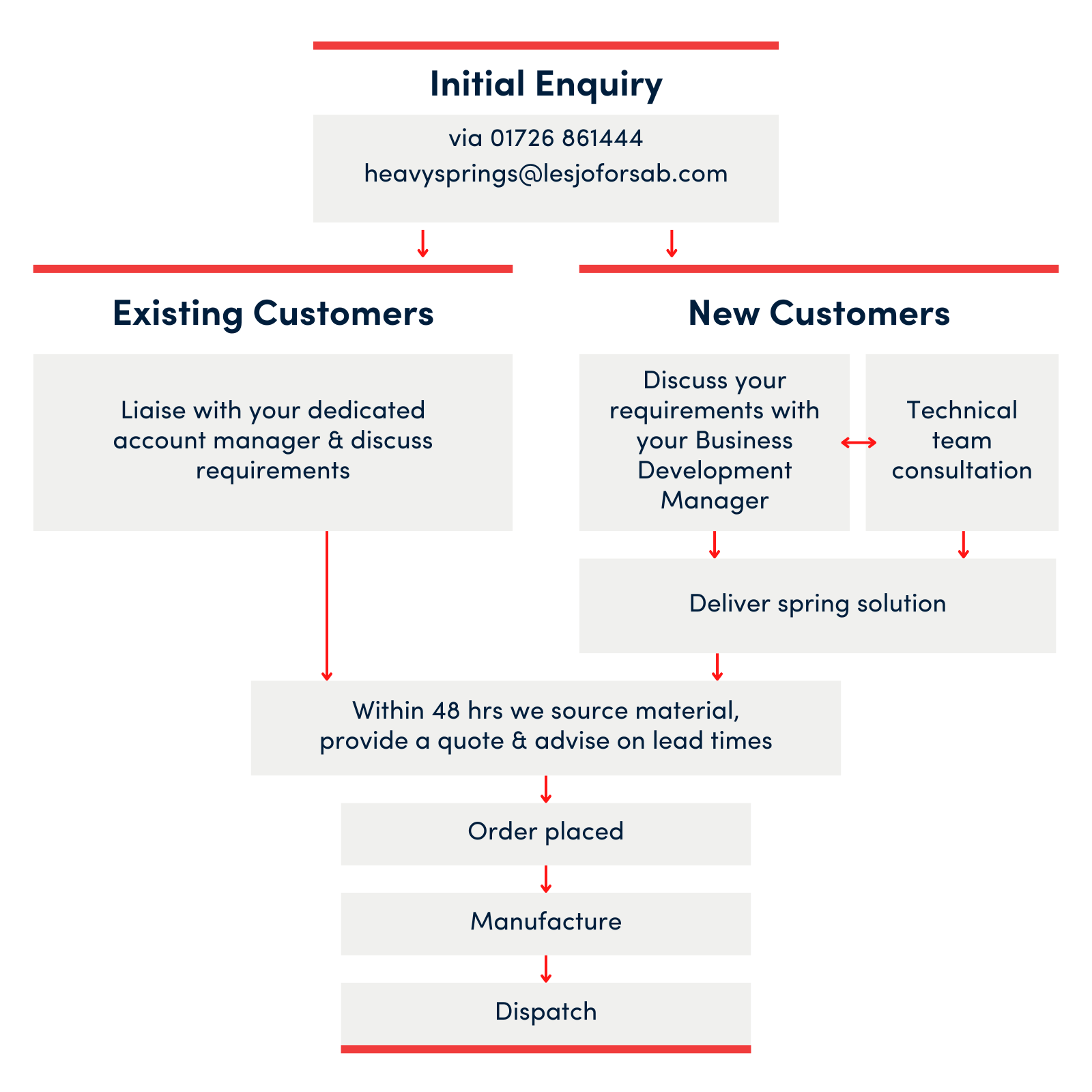

Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

Supplying the mining, quarries, aggregate, construction and other process associated industries, our heavy duty springs deliver vibration control, shock absorption and load management; bringing efficiencies and safety to OEM’s and suppliers within the quarry and mining equipment manufacturing industry.

The quarry and mining industry is reliant on durability and high production outputs in demanding conditions. Across surface mining and underground mining in screeners, crushers, conveyor systems, drills and breakers, excavators, trucks and loaders - the spring is an essential high performance component of their design. We design, engineer and manufacture custom springs for mining machinery to suppliers with world-wide reputations. Our key goal is to secure a significant competitive advantage for our customers through the provision of enhanced spring design and spring materials for mining equipment that delivers on performance, durability, optimum product life cycle and cost efficiencies.

We continually invest in the best and can design, quote, manufacture and dispatch your product within industry leading turnaround times at competitive prices.

From one to one million springs and beyond, there are no limits to the volume of spring manufacturing we offer.

We can help improve your supply chain and gain efficiencies through volume manufacture by stocking and storing your spring products. To discuss further, please contact your account manager or get in touch at heavysprings@lesjoforsab.com.

Require a certain type of freight, need your product packaged a specific way? Let us know how you would like your product packaged and our dispatch team will handle the rest.

Continual investment in our facilities and services keeps us at the leading design edge of quarry and mining machinery springs manufacturing. This allows us to lead from the front and to guarantee the maximum potential out of our custom mining springs through our expertise and technical analysis on the extreme stress boundaries of material capability and spring design. With our first class engineering and quality teams, technologies, manufacturing processes and advanced CNC spring coiling machines, we deliver bespoke spring design for mining equipment and an exceptional manufacturing service.

We are dedicated to delivering engineering excellence with a quality personal service and want to ensure that your journey from enquiry through to coil spring manufacture to dispatch is simple, seamless and excels at securing the spring solution you require.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy-duty spring solutions.

All our customers have dedicated account managers that oversee every step of the commercial and production process. Our team become an extension of your team, proactively positioned to understand and secure your requirements, to fast-track any urgent projects and to listen to your business needs.

Having manufactured custom springs for the mining industry for decades, we are continuously building a bank of knowledge and expertise in the field. We understand that spring design for mining equipment evolves as the exploration, processing and refining by mining companies evolves.

We know that springs work in a variety of regions, for varying applications in a multitude of differing equipment and are impacted by what particular mines produce. Our experience enables us to be agile to the demands of mining machinery springs and excel at achieving spring manufacturing standards in the mining industry.

Quarry and Mining equipment covers an expansive range of machinery with demands on the spring components within them to be able to handle the toughest applications. Our spring manufacturing process features the most advanced hot and cold CNC coiling capabilities delivering quarry and mining industry springs with large wire diameters. Our processes and spring manufacturing techniques for mining applications are designed to manufacture highly engineered springs that can withstand the extreme demands of the industry and deliver on quality, endurance and accuracy.

Matching our customers world-class performance expectations with advanced production technology and leading expertise, our technical, quality, engineering and production teams enjoy partnerships with mining equipment OEM’s and suppliers. The majority of our mining springs manufacturing projects are designing, developing and manufacturing custom quarry and mining springs to excel in the extreme environments of their operation.

All our projects start with consultations; establishing drawings to meet precise specifications and designing prototypes that evolve as the product design process evolves. Performance handling assessments, technical reviews, safety testing and failure analyses collaborate to direct the demands of the precision spring and secure the right custom springs for mining application performances. Manufacturing and consistently testing samples before full production runs, is all part of the product service and customer culture we believe in to achieve product optimisation for our customers.

In the demanding and high-stakes world of quarry and mining, every second counts. The accuracy and precision of coil spring design, development, and manufacturing can make all the difference in achieving optimal performance and safety. At our cutting-edge facilities, our top-tier engineering and quality teams, state-of-the-art technologies, and advanced CNC spring coiling machines enable us to deliver exceptional bespoke spring design and manufacturing services for the mining industry. Our continual investment in our facilities and services ensures that we remain at the forefront of precision mining spring manufacturing, allowing us to optimise the performance and safety of quarry and mining equipment by pushing the boundaries of material capability and spring design.

An essential part of the manufacturing process, heat treatment removes residual stress introduced to the material during the coiling process. The treatment stabilises the springs dimensions for greater accuracy and increased fatigue life and our oven facilities use forced convection technology to ensure the material is uniformly heat treated from surface to core. Our larger mining industry springs, using a wider wire diameter, require a hot winding process as the extreme heat allows large scale wire diameters to be coiled.

The process of heating up wire to approximately 900 degrees celsius, quenching in oil and tempered to complete the heat treatment, allows the spring material to be coiled to the specifications required.

Our teams consistently challenge the status quo looking to new material innovations, design optimisations and customised solutions to solve spring issues within the mining industry. Determined to be at the forefront of spring innovation, we significantly invest in our people and our facilities to ensure we continue to lead in heavy duty spring manufacturing.

We are also striving towards a more sustainable future. We recognise that climate-related issues are high on the sustainability agenda of our customers, suppliers, stakeholders, industry representatives, authorities and employees and we want to be transparent about the progress we’re making to optimise our product lifecycle and transition to a lower climate impact.

We are in discussions with strategic partners concerning greater access to raw materials with a lower carbon footprint and we’re working with our customers to enhance our product development process.

Yes. This is our area of expertise. Bespoke designing and manufacturing springs for a specific application within a challenging environment is where we thrive.

3D scanners, a variety of stress testers and numerous other testing procedures allow for the scrutinising of acquired data by our quality teams to guarantee quality, accuracy and durability.

We aim for 3-4 weeks. However, material supply and demand can affect timelines.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.