Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

Actuator valves might operate behind the scenes, but they’re essential to the performance of countless modern systems, from hydraulics and fuel injectors to HVAC and energy infrastructure.

At Lesjöfors, we have over 170 years of spring manufacturing expertise. Our heavy-duty actuator springs are engineered for performance and durability and are trusted across industries ranging from motorsport and construction to power generation and beyond. In this blog, we’ll take a closer look at how actuators function within valve systems, the different types of valve actuators available, and where they’re used in real-world applications.

An actuator is a mechanical device that controls the movement of a valve, determining when it opens, closes, or modulates flow. In industrial systems, they convert energy into motion – whether electric, pneumatic, hydraulic, or mechanical.

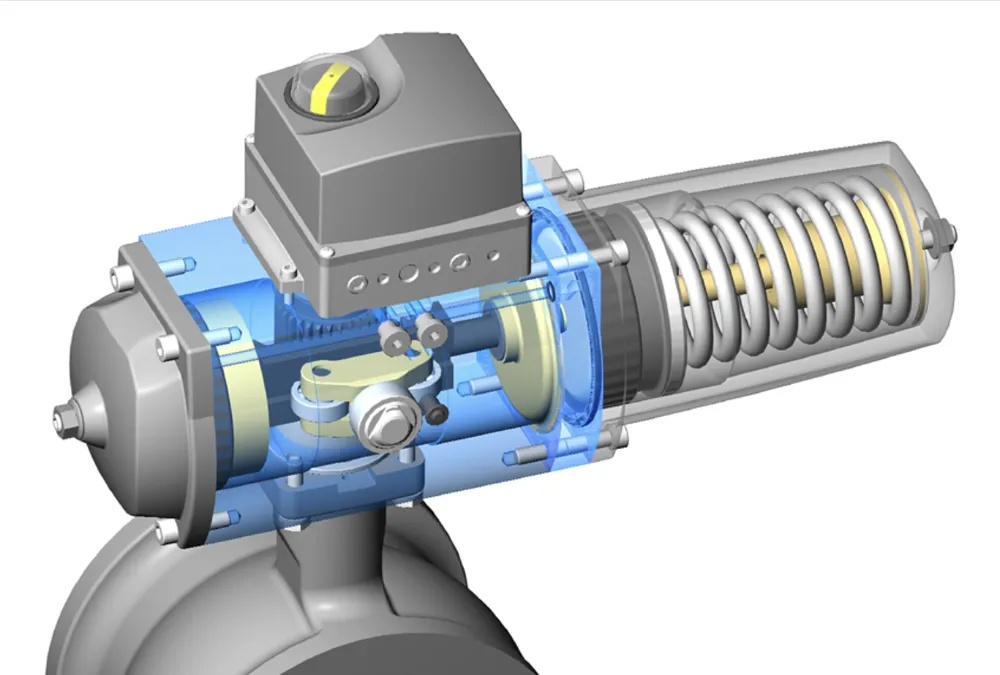

Actuators enable automated, precise control of fluid flow through pipelines and process systems. Valve springs play a critical role by delivering the force, stability, and return action required for reliable operation, particularly in fail-safe applications where valves must move to a defined position during power or signal loss.

We use actuators in industrial systems to control valves, enabling precise, real-time regulation of fluid flow. Actuator-driven valves respond to electrical, pneumatic, or hydraulic signals, converting them into motion.

In operation, a control signal is converted into mechanical motion – for example, a motor rotating a shaft in an electric actuator. This motion then adjusts the valve's disc or plug and causes it to open, close or modulate flow. This process can be controlled automatically based on real-time data (such as flow rate or pressure) and regulates the flow of liquids or gases through pipelines.

There are many types of actuator valves, including manual, pneumatic, hydraulic, electric, thermal and spring-based valves. Our coil springs are a key component in these valves, supporting their mechanical motion.

Manual actuator valves rely on human intervention to operate. These valves are controlled by quick and easy handwheels, levers, or gear mechanisms, making them simple, reliable, and ideal for systems where automation is not required. They are commonly used in applications where adjustments are not made frequently and precise control is not of high importance.

Pneumatic actuator valves use compressed air to control valve movement, which creates a fast and efficient operation. These valves are used in applications that require rapid cycling and in industries where air pressure is readily available. They are known for their reliability, low maintenance, and suitability for harsh environments.

Pneumatic rack and pinion actuators convert the linear motion of a piston into rotational motion to operate a valve. They are compact, efficient, and provide consistent torque output, which makes them suitable for quarter-turn valves such as butterfly valves or ball valves.

Spring-return pneumatic actuators automatically return the valve to a set position (usually closed) when the air supply is lost. This fail-safe feature is used in safety-critical applications, ensuring the valve reverts to a safe state during a system failure.

Hydraulic actuator valves use pressurised liquid to control valve movement, providing high force and precision. They offer excellent control in high-pressure environments. These valves are ideal for heavy-duty applications requiring strong actuation, such as in oil and gas, marine, and industrial processes.

Electric motors drive electric actuator valves, offering precise and programmable control over valve position. They are suitable for applications requiring fine adjustments and automation, such as heating, ventilation and air conditioning systems and water treatment plants. They can be easily integrated with control systems for remote operation.

Thermal actuator valves operate based on temperature changes, using the expansion and contraction of materials to move the valve. These valves are used in systems where temperature control is essential, such as in heating and cooling applications. They are a passive and energy-efficient solution for temperature-sensitive operations.

Spring-based valves use a mechanical spring (compression, tension, or torsion) to return the valve to a default position, usually closed, when the actuating force is removed. These valves provide a simple, fail-safe mechanism, ensuring that the valve reverts to a safe state during power or signal loss. They are commonly used in safety-critical applications.

Actuator valves are used across various industries such as motorsports, construction, transport, agriculture, renewable energy systems, oil, gas and petrochemicals, quarry and mining and robotics. Our springs are commonly behind the mechanics of the transportation and flow of fluids within the valve.

In motorsports, springs are used in actuator valves to ensure rapid and reliable control of fluid systems such as fuel injection, coolant flow, and brake systems. These springs help maintain consistent pressure and quick response times, optimising performance under high-speed and high-stress conditions.

In construction, springs in actuator valves are used in heating, ventilation and cooling systems, water management, and hydraulic equipment. They ensure valves return to a safe position during a power loss and prevent potential damage and safety hazards on-site.

In the transport industry, springs control fuel, air, and hydraulic systems in vehicles. For example, they are used in hydraulic actuator valves that control an airplane's landing gear, flaps, and brakes. They provide the necessary mechanisms to automatically close or open valves during power failures or emergencies and act as a fail-safe option.

In rail systems, actuator valves equipped with springs are used in braking systems, air conditioning, and hydraulic controls. Springs ensure valves automatically return to a default position during power interruptions or system failures, improving levels of reliability and safety.

In agriculture, springs are used in actuator valves to control irrigation systems, pesticide delivery, and machinery hydraulics. They ensure valves automatically close when not in use, which prevents leaks, conserves resources, and improves efficiency.

In renewable energy systems, such as wind and solar power installations, springs are used in actuator valves to control fluid flow in cooling systems, hydraulics, and energy storage systems. For example, in wind turbines, they control the hydraulic fluid flow, which adjusts the pitch of the turbine blades.

This helps optimise the turbine's performance based on wind speed and conditions. These springs and actuators also enable maximum energy capture while protecting the blades from excessive loads during high winds.

Springs are used in actuators in the oil, gas, and power industries to ensure the safe operation of pressure control, flow management, and safety shutoff systems. For example, they are used in deep-sea applications to automatically close in the event of system failure, preventing the environment from contamination and equipment from being damaged. They are helpful in these subsea applications where manual intervention is impossible.

In quarry and mining operations, springs in actuator valves are used to control dust suppression systems, slurry management, and dewatering processes. They provide a reliable fail-safe mechanism in harsh terrain and rugged environments.

In robotics, springs within actuator valves are used to control pneumatic and hydraulic systems that power robotic arms, grippers, and other components. These springs allow precise movement and enable robots to perform tasks accurately while providing fail-safe protection during system malfunctions.

The actuator is the control mechanism, instructing the valve when to open and close. They are commonly controlled by computer systems, which respond to monitoring systems and control valves that dictate the flow requirements needed through the valve.

The valve is the physical element that opens and closes, managing the flow control process of the fluid in the line. Our springs commonly operate in spring return actuator valves, and are designed with high-quality materials to be fit for purpose.

Working in synergy, the valve controls the volume of fluid passing through the system, while the actuator determines when and how that movement occurs.

At Lesjöfors, our springs are used across a wide range of valve drive and control systems, including:

There’s no question, actuators are the silent, systematic drivers behind performance and precision across industries, from motorsport to agriculture. They play a critical role in the function, efficiency, and safety of complex mechanical systems.

At Lesjöfors, we’re a global leader in springs, pressings and other components, and a trusted partner for actuator and valve components. With unmatched expertise and advanced manufacturing technologies, we deliver solutions built to perform under pressure.

Get in touch today to learn how our components can support your next application.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.