Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

In the world of heavy-duty springs, banana springs are often overshadowed by the traditional types of compression springs. However, these quietly underrated springs have unique properties that can handle loads both laterally and sideways, unlike traditional springs.

At Lesjofors, we design, develop and manufacture millions of springs every year, including banana springs for various industries. In this post, you will learn about banana springs, their characteristics and how they work. You will also explore real-life applications and receive tips about installing a banana spring safely and successfully.

Banana springs, also known as side load springs, are a type of coil spring designed to withstand forces from the side or angles that are lateral to its axis. These differ from conventional compression and extension springs that experience load along their length. Banana springs support mechanical motion in systems where components move in irregular paths or are subject to uneven forces. They also resist buckling and keep parts aligned in components that experience side impacts and shifting loads.

Banana springs are typically asymmetrical and curved, resembling the shape of a banana. Generally, the coil is reinforced with thicker wire and tighter coils to resist wear and buckling when subjected to lateral force. Usually, they are manufactured from high-strength materials such as alloy steel, stainless steel, or specialised composites. Often, they are manufactured with special end guides and designed to operate within specific housing structures to maintain alignment, improve load distribution and prevent side shifting in components.

Banana springs are engineered to resist side deflection. They store mechanical energy when compressed or stretched from both axial and lateral forces. They then release this energy in a controlled way, which helps maintain smooth motion in mechanical systems.

In many cases, the spring is designed with a controlled deflection range, which means it can handle axial and lateral forces without overstretching or compressing beyond safe limits. These springs distribute force evenly across coils, which prevents stress points in mechanisms experiencing lateral forces. They keep components aligned in systems where misaligned loads are common and are used in applications that do not have a clear, linear force path.

Banana springs handle compression and load differently than standard straight coil springs due to their curved geometry. As force is applied, a banana spring compresses along its curve; this force is distributed along the arc of the spring, which allows even deflection while reducing stress across specific points.

In some cases, a banana spring may provide a progressive spring rate, which allows for initial soft compression, followed by greater stiffness as the load increases. The arc-shaped structure also makes banana springs resistant to deformation under non-uniform loads.

Banana springs are used in applications in which standard straight springs do not fit, such as in compact systems and curved structures. Here is an outline of their use in various mechanical systems and industry applications.

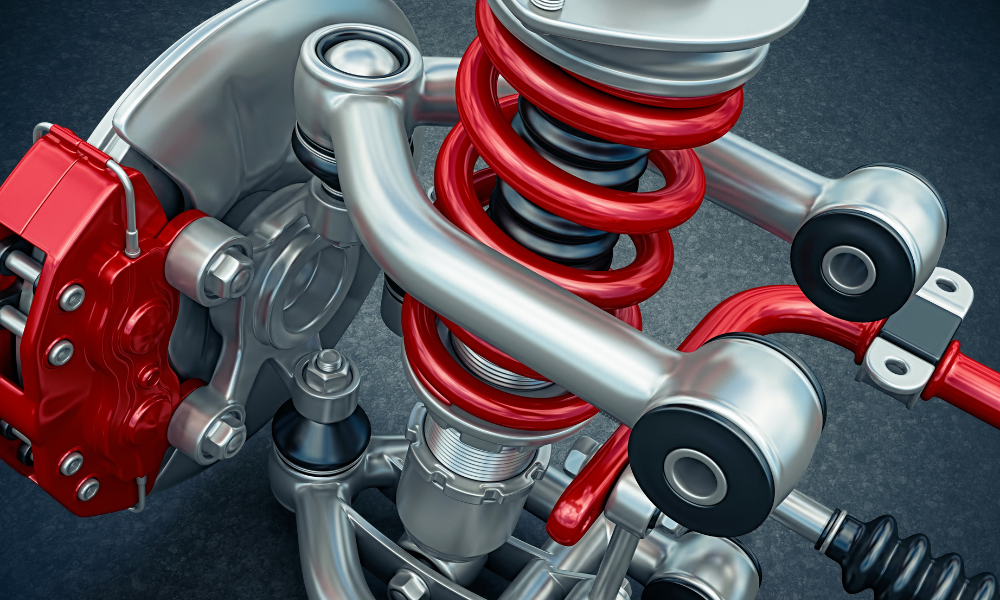

Banana springs are used in vehicle suspension systems to counteract side loads when a vehicle turns, hits bumps or travels over uneven surfaces. This maintains the suspension system and prevents wear and tear on the springs and other components, as well as buckling.

Banana springs are used as shock absorbers in vehicles and vibration dampers in buildings. They support energy absorption from all directions, increasing the durability of systems.

Railway systems use banana springs in suspension and buffer systems to handle lateral forces caused by curved tracks and uneven weight distribution. They maintain the alignment of railway cars and support a smooth, safe ride even whilst experiencing side forces.

Vibration isolators are used in industrial equipment and building infrastructure, such as heating, ventilation and air conditioning systems. Banana springs are used to isolate forces from multiple directions, increasing stability and reducing sound vibrations.

Banana springs support systems where parts move in unpredictable paths, such as robotic arms. These springs improve accuracy and durability by absorbing lateral forces and keeping the robot's components in precise alignment.

In motorsports, banana springs manage the extreme lateral forces that race cars endure during high-speed cornering, acceleration and braking. They absorb side impacts, provide chassis stability and improve handling during rapid directional changes.

Aircraft and spacecraft components often experience complex forces that don’t align with the central axis of parts. Banana springs are used in landing gear systems and actuator mechanisms for control surfaces, such as ailerons and rudders. These support smooth landing when an aircraft touches down at an angle and smooth manoeuvres in various flight conditions.

In agriculture, banana springs are used in machinery that operates on uneven terrain. Often, they are used in tractor suspension systems, hydraulic arms on harvesters and plows and tillage equipment to help manage uneven forces from rocky land or sloped grounds.

Banana springs are used in quarry and mining systems such as crushers and screening equipment, conveyor systems, drilling equipment and heavy vehicle suspensions. They handle misaligned loads, reduce stress on equipment and ensure smooth operation.

In the energy industry, banana springs are used in valve actuator systems to control the flow of liquids and gases through pipelines and tanks, which often experience side loads due to fluid pressure changes and misalignments. They also support equipment like drill bits, drill strings, and pumps working under immense pressure and lateral forces.

There are many advantages to using banana, or sideload springs. These include increased durability, load distribution efficiency and cost-effectiveness. Banana springs also prevent misalignment, enhance stability and extend the lifespan of components.

Banana springs are typically made from high-strength materials which can endure cyclical loading without cracking, bending or deforming. They are engineered to withstand lateral loads and resist premature wear and tear more effectively than standard springs.

Some banana springs may be designed to work in harsh conditions such as extreme temperatures or corrosive environments, making them durable in industries such as mining, aerospace and energy sectors where they are exposed to moisture, dirt and chemicals.

Unlike standard springs, which may experience certain stress points under lateral load, banana springs spread the load evenly across the coils. This means that the entire spring works to absorb the force rather than excess stress building in one area.

This efficient load distribution prevents damage to the spring, as well as equipment. These springs are also able to adapt to varying load conditions, which makes them useful in components, such as motorsports, that experience rapidly changing forces.

Banana springs offer a cost-effective solution by reducing the need for frequent maintenance. This saves labour costs, prevents system downtime and extends the equipment's lifespan. It is also possible for banana springs to minimise misalignment and friction, which reduces energy waste and lowers operational costs.

At Lesjöfors, we design and manufacture world-leading heavy-duty springs, including high-quality, efficient and durable banana springs. Whether you are looking for a high-performance spring for motorsports vehicles or a specialised spring that meets the demands of harsh quarry and mining environments, we can support you.

Our advanced production facilities and high-end CNC spring coiling machines deliver custom spring solutions to help you optimise your spring and your success.

Want to find out more about custom spring solutions?

Contact our expert team today.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.