Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

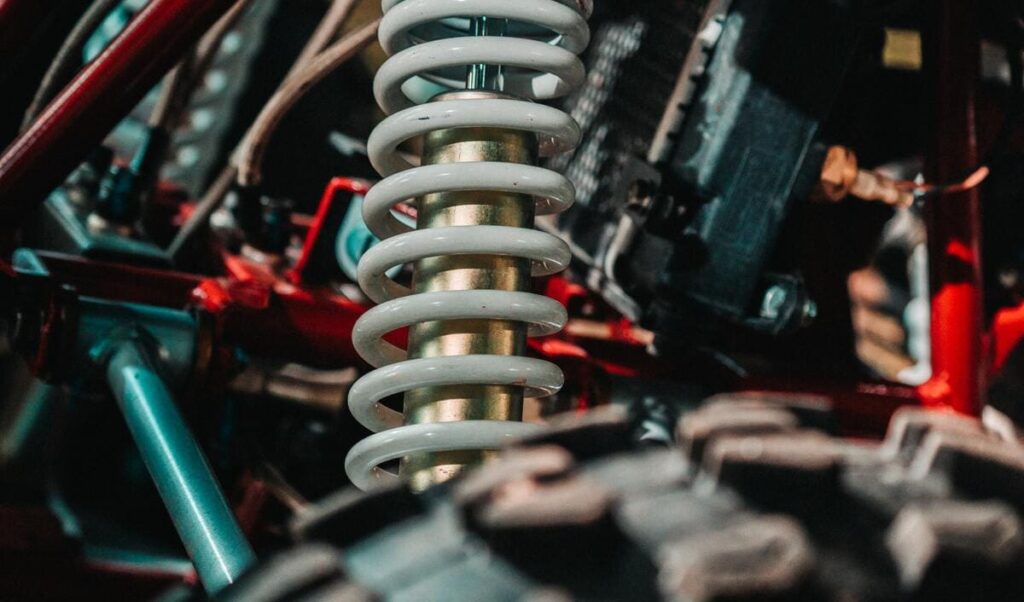

From high-speed motorsports to heavy-duty transport, vehicle suspension springs ensure optimal handling, stability, and performance. As a leading suspension springs manufacturer, Lesjöfors delivers precision-engineered solutions for motorsport teams and automotive manufacturers worldwide. From competitive racing to commercial vehicles, we’ve been supplying coil springs to the automotive aftermarket for decades.

With our expertise in commercial suspension springs and high-performance applications, we engineer products that withstand extreme forces and maintain precise control. In this blog, we’ll explore the role of suspension springs and how they can enhance or hinder vehicle performance and comfort.

Suspension springs have evolved. Initially, vehicles used leaf springs, consisting of stacked metal strips, to absorb shocks from uneven terrain. As automotive technology advanced, coil springs became popular, offering improved comfort and handling.

In modern suspension systems, high-performance materials like alloy steel and titanium are employed, especially in motorsports, enhancing durability, reducing weight, and optimising vehicle performance

From cars to freight trucks, road sweepers to superbikes, vehicles use various types of suspension springs, each tailored to that specific application. Coil compression springs are the most common type used in vehicle suspension systems due to their compact design and shock-absorbing efficiency. Torsion springs, which resist twisting forces, can also feature, and tension springs are common in applications that need high tensile strength, providing resistance to pulling forces.

The quality of car suspension springs directly impacts performance and safety. High-quality springs provide precise handling, stability, and comfort by effectively absorbing road irregularities and maintaining tire contact with the surface.

In motorsports, precision-engineered springs are crucial for achieving optimal suspension dynamics, enhancing control and competitive advantage. They can also help stabilise weight distribution and reduce the likelihood of rolling.

Steel grades play an important role in spring performance and durability. Lesjöfors uses high-quality materials such as chrome silicon and chrome vanadium to manufacture springs that can withstand extreme environments. In fact, we hold one of the largest stocks of chrome silicon and chrome vanadium wire anywhere in the world. The right choice of steel grade ensures optimal strength, fatigue resistance, and longevity, crucial for demanding applications like motorsports.

At Lesjöfors, we use state-of-the-art manufacturing technologies to produce high-performance vehicle springs. With hot and cold CNC coiling handling wire up to 80mm in diameter (for industries that require a larger wire size), we ensure precision, quality and quick turnaround times. Our advanced surface treatments also enhance longevity, making our springs the choice of leading motorsport and automotive brands.

Vehicle suspension springs can last anywhere from 50,000 to 100,000 miles. This varies significantly depending on the type of vehicle, usage and the spring quality, so it's important to monitor for signs of failure.

Look out for corrosion, unusual noises, or uneven ride height. If a spring is broken, replace it in pairs to maintain even suspension geometry and ride height, preventing further issues such as uneven tire wear.

Inspections help identify wear before it affects performance or safety. Check for corrosion, cracks, or uneven ride height at least annually or during routine servicing. Measuring ride height can reveal sagging, and replacing worn springs in pairs ensures balanced handling and prevents further suspension issues.

At Lesjöfors, sustainability is integral to our business operations and product development. We follow a robust Code of Conduct regarding environmental responsibility, resource efficiency, and ethical practices across the value chain. Reducing our environmental impact and optimising our resources are our key priorities, ensuring we deliver the highest quality products with as little environmental impact as possible

As electric and autonomous vehicles become more prevalent, suspension systems are evolving to meet new demands. Lesjöfors is at the forefront of this shift, manufacturing lightweight, energy-efficient springs that complement the unique characteristics of electric drivetrains. With adaptive technologies and smart systems, the company ensures its solutions support the future of the automotive industry.

From transport to motorsports, we proudly manufacture precision-engineered vehicle suspension springs for some of the industry’s most trusted brands. With 170 years of expertise, we ensure every spring meets the highest standards for performance and durability. Partner with us for superior suspension solutions – contact our team today to discuss your specific requirements.

To find a vehicle’s ride height from spring stiffness, divide the weight supported by each spring by the spring rate. This gives the amount the spring compresses from its unloaded height.

No, a broken suspension spring compromises handling, ride comfort, and safety, making the vehicle unroadworthy.

Leaf springs provide durability, high load capacity, and cost-effectiveness, making them viable options for trucks and heavy-duty vehicles.

The cost of replacing a suspension spring will vary by vehicle and installer.

Driving with a broken suspension spring is unsafe and can cause further damage.

Uneven ride height, excessive bouncing, poor handling, knocking noises, or uneven tire wear can indicate failing suspension springs.

The cost of replacing springs will vary depending on the vehicle and the parts used.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.