Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

In the intricate world of mechanical design, compression springs play a pivotal role. This blog delves into the diverse types of springs, focusing on their unique designs, applications, and the specific advantages and limitations they bring to various industries. So, what are the different types of compression springs?

Compression springs are a critical component in many mechanical systems, offering versatility and efficiency in a wide range of applications. Types of compression springs include straight coil springs, convex springs (barrel) , concave springs, conical springs, variable rate springs (dual rate springs) and banana (sideload) springs. They are designed to operate with a compressive load and find use in the automotive, aerospace, and manufacturing industries.

Understanding the various types of compression springs is vital for engineers and designers. Each type offers unique characteristics in terms of load capacity, durability, and potential applications. Selecting the right type of compression spring can significantly impact a mechanical system's performance, safety, and longevity. Knowledge of different spring types enables informed decisions, ensuring optimal functionality and cost-effectiveness in design and application.

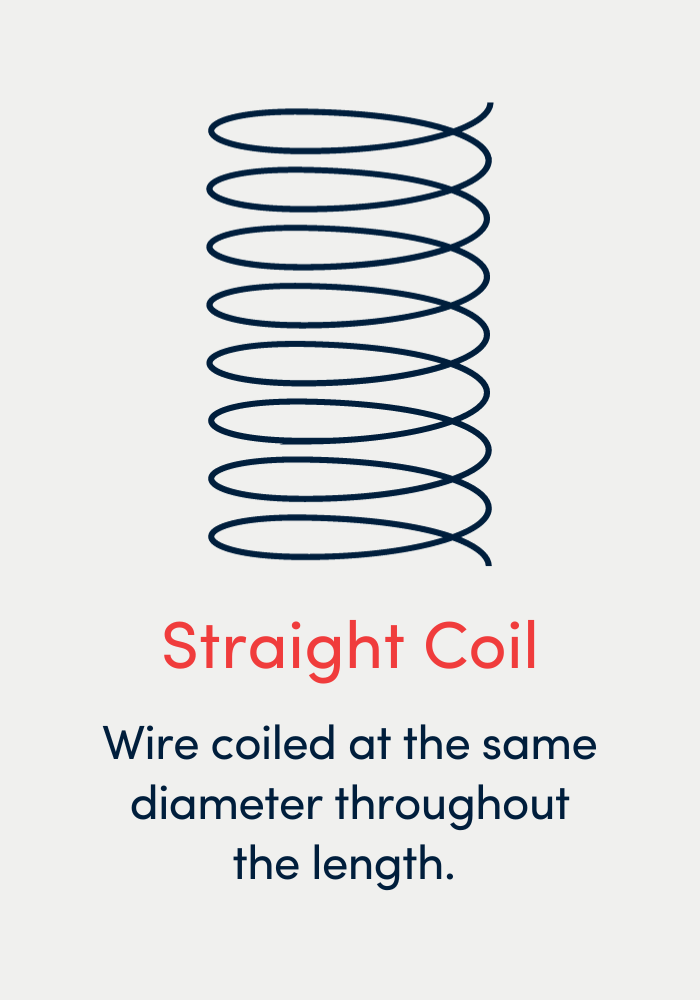

Straight coil springs are fundamental in a multitude of mechanical systems, recognised for their simplicity and effectiveness.

These springs are characterised by their linear coil design, which is uniform in diameter throughout. The design process involves meticulous considerations of wire diameter, coil diameter, material type, and the number of coils. These factors collectively determine the spring's strength, flexibility, and load-bearing capacity; manufacturing precision is paramount to ensure consistent performance and durability.

Straight coil springs are extensively used in automotive suspension systems, electronic devices, and industrial machinery. Their ability to absorb shock and maintain force between contacting surfaces makes them indispensable in environments where stability and reliability are crucial. Additionally, Tractors and other heavy-duty agricultural machines use these springs to handle the stresses of ploughing, harvesting, and other farm activities.

The primary advantage of straight coil springs lies in their straightforward design and efficient energy storage capacity. They provide a robust solution for systems requiring a predictable and uniform response to compressive forces. However, limitations arise in terms of material fatigue and the potential for deformation under excessive load. Careful design and material selection are essential to mitigate these issues and ensure long-term functionality.

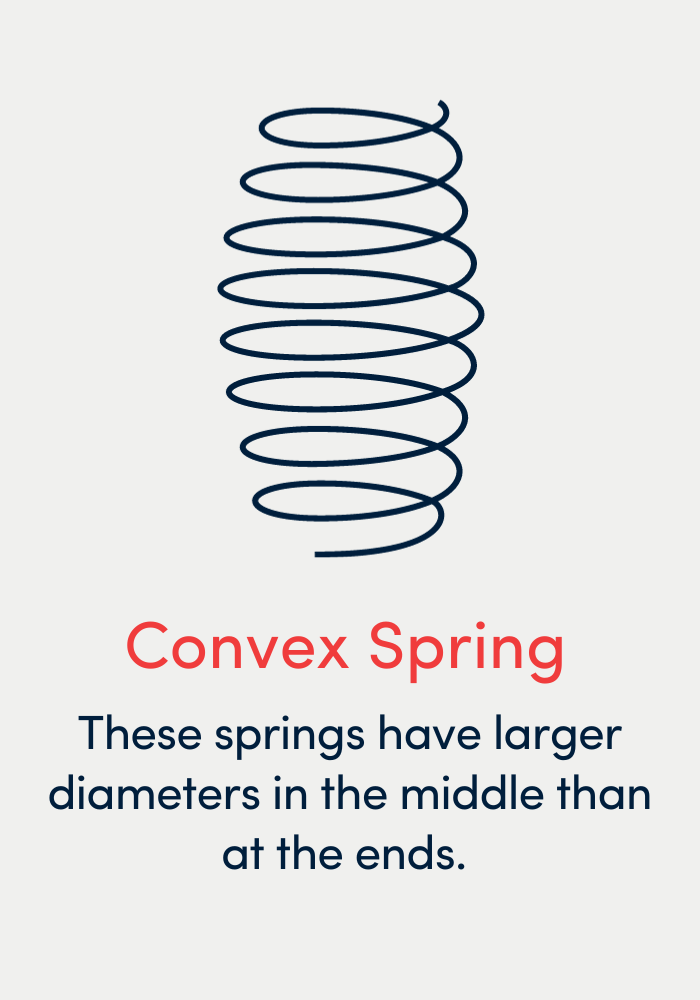

Convex springs are integral to numerous mechanical systems, distinguished by their unique curved design.

Convex springs, distinct from traditional straight coil springs, feature a curved or bulged profile. The design of these springs is sophisticated, requiring precision in the curvature to ensure an even distribution of stress when compressed. Factors such as the degree of curvature, material properties, and overall dimensions define the spring's characteristics and performance.

These springs are commonly employed in applications where space is limited or where a more concentrated load is required. Their unique shape makes them ideal for certain types of valves, actuators, and clutches, especially in the automotive and aerospace industries. Moreover, in construction machinery like excavators, cranes, and bulldozers, convex springs help in managing the heavy loads and rough usage conditions.

The main advantage of convex springs is their ability to provide a high force in a compact space due to their curved design. This makes them suitable for high-stress applications. However, they may have limitations in terms of manufacturing complexity and costs. Also, the specialised design might restrict their use to specific applications where their unique properties are most beneficial.

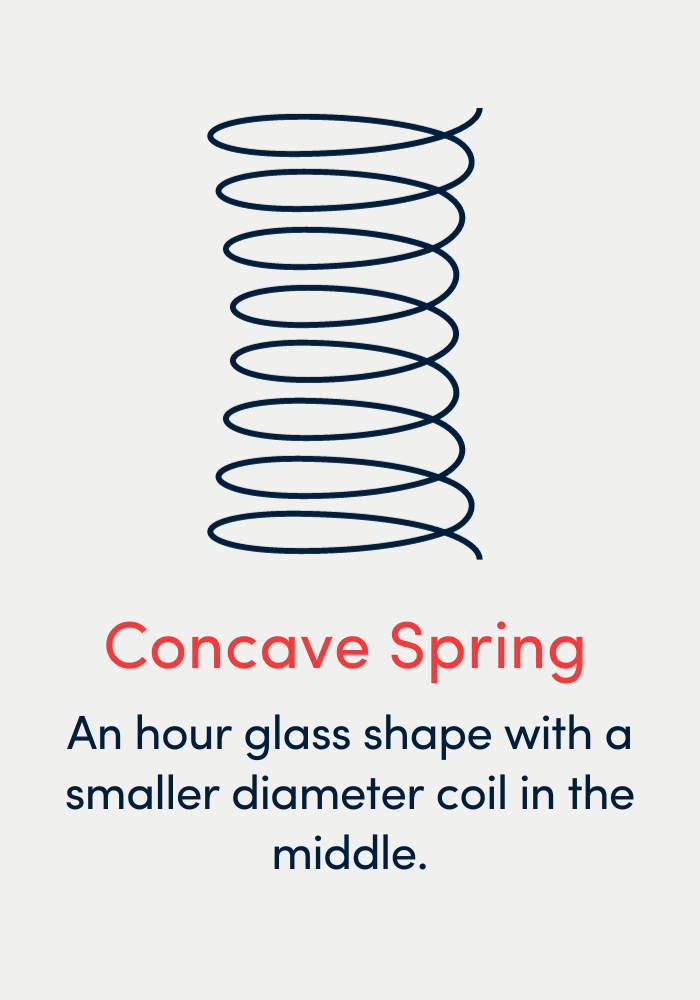

Concave springs are distinct in their tapered design and are valued for their enhanced stability and load distribution efficiency.

Concave springs, also known as barrel springs, are characterised by their tapered shape, which has a smaller diameter in the middle and is wider at the ends. This design distributes stress more evenly across the spring. The wire's diameter, the tapering degree, and material type are key factors influencing the spring's performance.

These springs are often utilised in applications where stability is crucial, such as in automotive suspensions and electronics. The unique shape helps prevent buckling under compression, making them suitable for compact spaces where traditional springs would not fit. Train carriages and locomotives use concave springs in their suspension systems for better stability and shock absorption in a compact form. Additionally, in applications like wind turbines and other energy-generating equipment, concave springs are used for their durability and efficiency in compact setups.

The primary advantage of concave springs lies in their enhanced stability and resistance to buckling, ideal for uneven load distributions. However, their specialised design can lead to higher manufacturing costs and complexity. Additionally, their application may be limited to specific scenarios where their unique shape offers a distinct advantage.

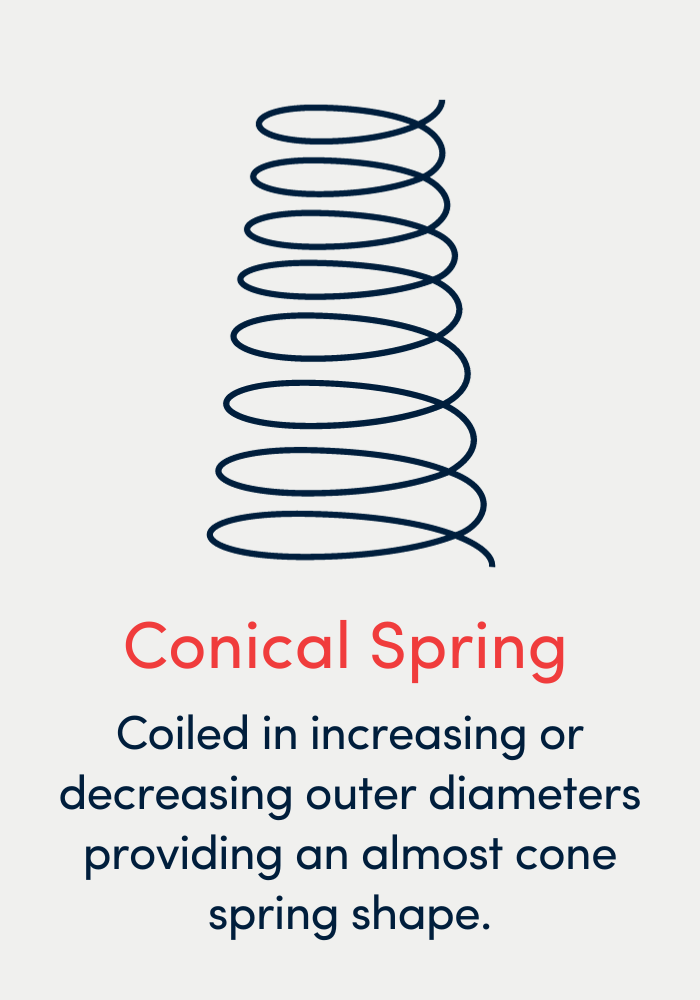

Conical springs are crucial in various mechanical systems and are known for their adaptable design and efficient load management.

Conical springs, known for their cone-shaped design, offer a unique configuration where the diameter of the coils decreases towards one end. This design is engineered for precision, ensuring effective operation under varying stress conditions. Material choice and coil dimensions are tailored to specific requirements, emphasising performance and durability.

These springs are commonly found in applications where space is limited and a variable rate of force is needed. They are used in mining industries where equipment such as crushers, vibrating screens, and feeders often use conical springs. Their ability to absorb high impact forces and vibrations, while maintaining stability, is crucial in these applications. Due to their compact nature and ability to be compressed to a nearly flat state, conical springs are often used in robotics where space is limited. Their progressive spring rate can be advantageous in handling varying loads, which is common in robotic arms and actuators.

The primary advantage of conical springs is their ability to fit into smaller spaces while providing a progressive rate of compression, making them suitable for complex mechanical systems. However, their intricate design can pose manufacturing challenges and potentially higher costs. Their specialised nature may also limit their use to specific applications where their unique benefits are most advantageous.

Variable springs are pivotal in a wide array of mechanical systems, renowned for their adaptable functionality and precision engineering.

Variable springs (also called dual rate springs), feature an adaptable design and are engineered to provide varying degrees of force within the same spring. This versatility is achieved through a combination of unique coil geometries and variable pitch, which allows the spring to adjust its characteristics based on the applied load.

These springs find their utility in applications demanding flexibility and responsiveness, such as in vibration isolation, machinery, and adjustable seating. Their adaptability makes them particularly useful in environments where conditions and requirements frequently change.

The main advantage of variable springs lies in their ability to provide different levels of support or resistance within a single component, enhancing their applicability across diverse scenarios. However, this complexity can lead to challenges in design and manufacturing, potentially increasing costs and limiting their use to applications where their unique properties offer substantial benefits.

Banana/sideload springs are a less common type in the spring family and are designed to handle loads applied laterally or sideways. This unique feature requires a distinct structural approach to ensure stability and effective load distribution. The design often involves considerations for asymmetrical shapes and specific material properties to withstand sideload pressures.

These springs are particularly useful in applications where space constraints prevent the use of traditional springs or where the load is inherently unidirectional. Examples include certain automotive components, such as the suspension systems of vehicles.

The primary advantage of banana springs is their ability to function effectively under lateral stress, a scenario where conventional springs might fail. However, their specialised design can be more complex to manufacture, potentially increasing costs. Also, their niche application means they might not be as widely applicable as more conventional spring types.

Here are some industry examples of the types compression spring applications for each type of spring.

Used in suspension systems and for relays and switches in electronics where reliable, consistent force is essential.

Used in suspension systems, aerospace engineering, industrial machinery and equipment.

Used in suspension systems, furniture manufacturing (mattresses) and heavy-duty industrial machinery.

Used in battery contacts, push buttons, engine valve systems, and industrial machinery.

Used in vibration-dampening systems (construction), adjustable seating and suspensions (automotive) and industrial machinery.

Door mechanisms and latches (automotive), machinery that requires lateral movement (industrial equipment).

Selecting the appropriate type of spring for any mechanical application hinges on a variety of factors, here is an overview of each factor involved.

Choosing the right spring type starts with understanding the load requirements. It's essential to consider both the magnitude and nature of the load, whether it's static, dynamic, or variable. The spring rate, which is the force required to compress the spring by a unit length, needs to be aligned with the load requirements of your application. A spring that's too stiff or too soft can fail to function effectively.

Space constraints often dictate the size and shape of the spring. The design must ensure optimal functionality within the available space. Key dimensions such as wire diameter, outer diameter, free length, and number of coils play a crucial role in the spring's characteristics. These dimensions should match the load and space requirements of your application.

Compression springs come with different end types, like closed or open ends, and ground or unground. The end type affects how the spring distributes the load and sits in the assembly. Ensure the end type is compatible with the mounting requirements.

Budget constraints play a crucial role in spring selection. While quality is paramount, the cost must align with project budgets.

The choice of material affects the spring's strength, flexibility, corrosion resistance, and temperature tolerance. Compression springs can be made from various materials, including stainless steel, music wire, chrome silicon, and more. The choice of material depends on factors like temperature, corrosiveness of the environment, and required lifespan, such as temperature, humidity, and exposure to chemicals, can significantly impact spring performance and longevity. For instance, stainless steel is preferred for corrosive environments.

While standard springs are readily available and cost-effective, certain applications might require custom-made springs. Custom springs offer the advantage of being tailored exactly to your specific requirements.

Selecting the right spring involves balancing these factors. It requires a comprehensive understanding of the application and technical knowledge of spring dynamics. By considering these factors, you can make an informed decision and select the right type of compression spring that offers reliability, efficiency, and longevity for your application.

When in doubt, it’s always beneficial to consult with spring manufacturers or mechanical engineers. Their expertise can guide you in selecting the most appropriate type of compression spring for your specific needs.

As we conclude our exploration, let's recap the diverse types of compression springs: straight coil springs, convex (barrel) springs, concave springs, conical springs, variable rate springs and banana (sideload) springs.

Our understanding of these components has deepened from the straightforward functionality of straight coil springs to the specialised uses of convex, concave, conical, variable, and sideload springs; each has its own purpose across automotive, aerospace, electronics, construction and industrial machinery industries. When selecting a spring for an appropriate application, the key takeaway is to consider load requirements, space constraints, environmental factors and cost.

If you would like to learn more about compression spring mechanisms and how they work or explore their applications at a deeper level, you can find further information on our blog. You may also be interested to read about how we designed, tested and manufactured suspension springs for limited edition performance cars!

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.