Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

In this post, we will explore tension spring application in everyday life, common materials used and how they work. We will also outline tension spring uses in various industries, such as aerospace, medical devices, agriculture machinery and motorsport.

As expert heavy-duty tension spring manufacturers, we design, engineer and manufacture millions of tension springs for custom specifications.

Here is our ultimate guide to tension springs and their applications.

Below, you will find the definition of a tension spring and a mechanical description of how tension springs work.

Tension springs operate under tension, elongating when a load is applied and returning to their original length when the load is removed; in its original position, a tension spring has tightly wound coils. They absorb and store energy and maintain a force between contacting surfaces, making them essential in mechanisms that require pulling forces. They are also known as extension springs and are used in various applications, from automotive assemblies to home appliances.

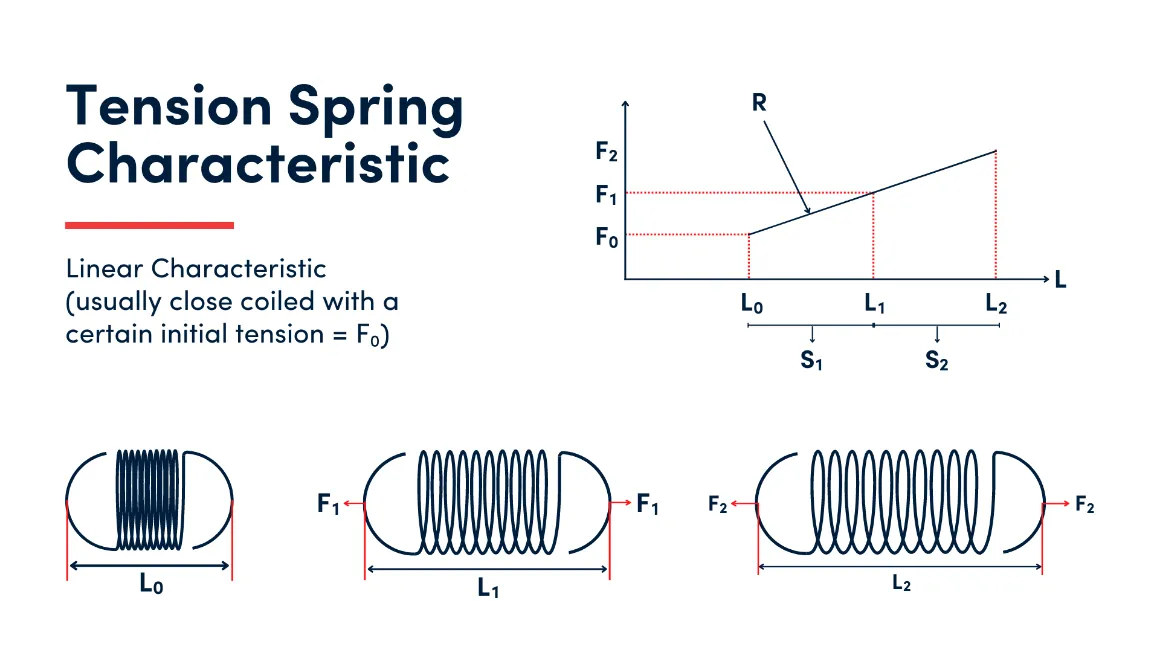

The mechanics of tension springs are governed by Hooke's Law, which states that the force needed to extend a spring is directly proportional to the displacement. These springs are characterised by their initial tension, the minimum force required to overcome the internal force and begin extension. The initial tension is set during the manufacturing process and a spring is stronger when coiled to a higher initial tension. Other factors to consider in the mechanics of tension springs include spring rate (the change in force with respect to the change in length), material properties, and design parameters such as coil diameter and wire size. These factors contribute to the spring's functionality and suitability for specific applications.

Tension springs are used in mechanisms that require a pulling force; they resist the force placed upon them and are used to pull two components back together once the force is removed. They are commonly used in agricultural machinery, aerospace components and construction equipment and support energy absorption and movement control.

In the realm of tension springs, a diverse range of materials and designs are used to cater to specific requirements. Let’s explore these factors in more detail and look at the type of spring hooks below.

Common materials used to craft tension springs include stainless steel, high-carbon steel, Inconel and phosphor bronze. Stainless steel is known for its corrosion resistance and durability, making it ideal for indoor and outdoor applications. High-carbon steel is known for its high tensile strength and flexibility. Alloys such as Inconel or phosphor bronze are used in applications requiring resistance to heat or chemical exposure. As you can see, materials are selected for their unique properties and suitability for specific environments and functions.

Tension springs can be classified based on their design and the specific applications they serve. The most common types include the standard coil tension springs, which provide direct linear force and are widely used in mechanical devices.

Conical tension springs, in which the diameter of the spring body is smaller at each end, the main reason for decreasing the outer diameter of a tension spring is to ensure it fits properly, whether to allow for the inclusion of an end attachment like a swivelling hook or a bolt of standard size, or to diminish the diameter for a standard hook. Tension springs may also feature different end types, such as machine hooks, cross-over hooks, side hooks and extended hooks.

Tension springs are used in a wide range of daily household items, ranging from smaller household items such as pens to larger appliances such as washing machines. In this section, you will find an overview of how tension springs are used in daily household items as well as within a range of industries.

Tension springs are used in household items, such as retractable pens, screen doors, and washing machines. They ensure functionality and ease through their ability to maintain force and facilitate movement, used to support the smooth operation of many home appliances and fixtures.

In the realm of recreation and sports, tension springs are used in equipment such as trampolines and fitness machines. They provide necessary resistance and support and enhance performance and safety. They may also be used in archery bows for power and precision, fishing rods for reel tension, and bicycle suspension systems.

Tension springs are used in various industrial machinery components in the agriculture, energy, transport, construction, mining, oil, gas and robotic sectors. Let’s look at specific examples in the construction and mining industries below.

Tension springs are used in construction equipment, such as cable retraction systems in cranes, excavators (for controlling the tension of tracks or cables) and concrete mixers. They are also used in mining in conveyor belt systems for tensioning and alignment, vibrating screens for material sorting and separation, rock crushers for applying consistent pressure, and drill rigs for stabilising and absorbing shock. They provide essential force for the operation of industrial tools by absorbing energy and facilitating controlled movement under demanding conditions.

Tension springs are used in a variety of medical and health applications, from surgical instruments to resistance training machines. Let’s look at some specific examples below.

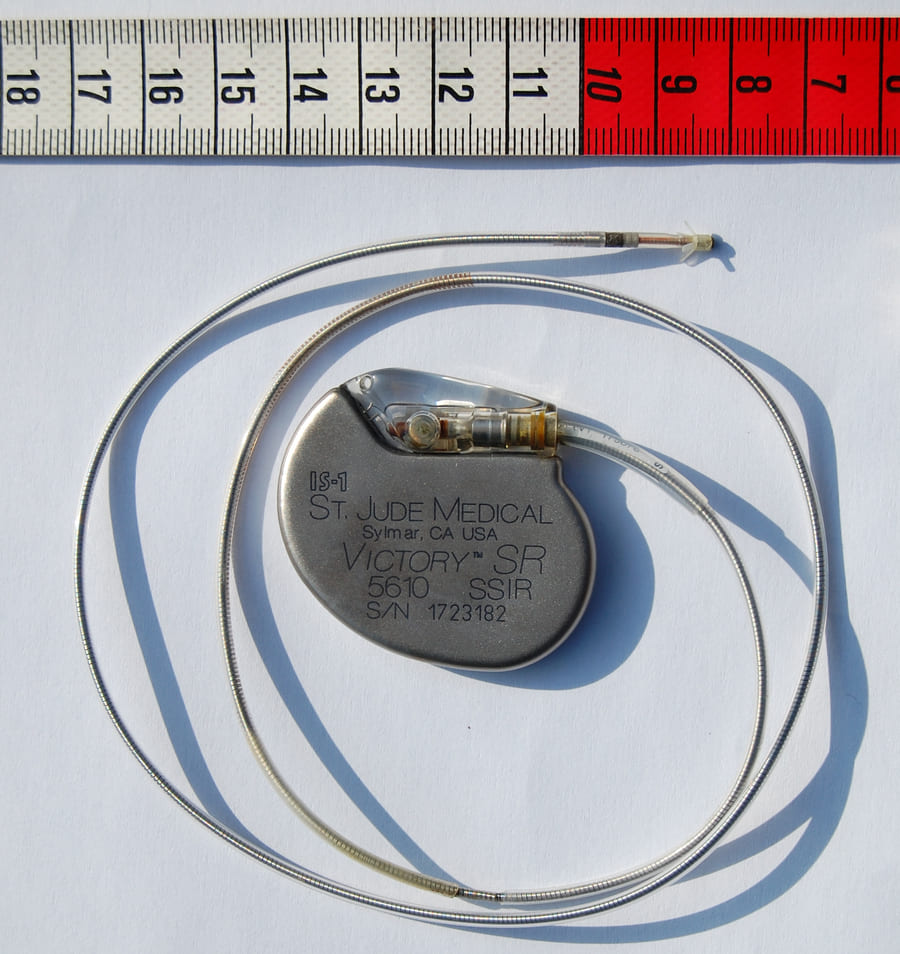

Tension springs are used in medical devices such as surgical instruments, retractable syringes and orthodontic devices. For example, orthodontic braces use tension springs to provide a gentle force on teeth. They may also be found in hospital equipment, such as ventilators, to provide the tension needed to open and close valves and allow oxygen to pass through.

In exercise and rehabilitation, tension springs are used in resistance training machines, physiotherapy devices and mobility aids. For example, they are used in hand grip strengtheners to improve grip strength, pedal exercisers, and balance boards to adjust resistance levels and provide stability. This supports the recovery and conditioning of a patient's health.

There are multiple uses for tension springs in the aerospace and defence industries. Their durability and performance make them suitable for high-stress environments within these industries. Let’s look at some specific examples below.

In the aerospace industry, tension springs are used in control systems, retractable landing gear systems and engine components. For example, they may be used in flap and slat mechanisms for wing adjustments and in landing gear systems to ensure smooth extension and retraction of components. They are also found in seat reclining systems and door-latching mechanisms.

Tension springs are used in recoil mechanisms in firearms, in vehicle suspension systems to enhance performance on rugged terrains and in parachutes, where springs are crucial for harness adjustments and canopy deployment.

They are also used in personal protective gear, in adjustment mechanisms for helmets and vests, and in communication devices, for retractable antennas and battery compartments.

Tension springs are used in agricultural machinery, such as in tractors for clutch and brake mechanisms, in balers to maintain tension on belts and strings, and in plough equipment for adjusting and maintaining depth.

Other examples include seed drills for precise seed placement, cultivators for soil aeration and weed control, and irrigation pivots for consistent water distribution.

In the realm of horticulture, tension springs are used in pruners, loppers, and grass shears. These springs provide the necessary force for opening and closing actions, reducing user fatigue and improving precision in cutting and trimming tasks.

Tension springs can be used as part of the suspension system to manage loads when constructing roofs and bridges due to their ability to facilitate movement.

They are used on roofs in sports stadiums to support retractable elements (enabling them to open or close depending on weather conditions).

Plus, they are used in seismic dampers within buildings to enhance earthquake resistance through absorbing and dissipating energy.

In safety and security devices, tension springs are used in fire safety doors, emergency exit mechanisms, and locking devices. They provide the necessary force for automatic closures and secure locking, enhancing safety measures in buildings and construction sites.

In the automotive industry, tension springs are used in brakes and clutches. For example, in clutch assemblies, they support the engagement and disengagement process, and in breaking systems, they move the brake pads away from the rotor.

They are also used in seatbelt retractors to support the overall safe operation of vehicles.

Tension springs are used in railway signalling equipment such as relays and track circuits. For example, in relay contacts, tension springs keep components together, even when vibrations are present, and allow the relays to make electrical contact; this support tracks circuits to reliably detect when a train is on its way.

In conclusion, tension springs are highly versatile mechanisms that have a multitude of applications, ranging from smaller household items to larger industrial machinery. They can be crafted from a range of materials, be manufactured with various levels of initial tension and range in terms of style and hook types.

As heavy-duty spring suppliers, we design and manufacture heavy-duty tension springs UK-wide and across the globe for various industries and applications.

Want to receive a prototype or sample?

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.