Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

Rail infrastructure and tracks generate a large amount of noise and vibration. However, there are various ways to manage rail noise reduction, including using heavy springs. This post outlines the types of heavy springs used in rail applications, the benefits of heavy-duty springs and how they can reduce noise pollution from trains.

The interaction between train wheels and tracks creates rail noise pollution. This noise can affect nearby residents and disrupt wildlife habitats. Many sources of rail noise pollution exist, including:

Strategies such as installing noise barriers, using rail grease or lubrication, employing quieter rolling stock, maintaining track infrastructure, and using heavy springs can effectively support rail noise reduction.

Springs absorb and dissipate mechanical energy generated during train operations, minimising vibrations that lead to noise pollution. Understanding the mechanics of springs allows for strategic placement and optimisation in rail systems to achieve the best noise reduction outcomes.

The basic principle behind using springs for noise reduction lies in their ability to convert kinetic energy from vibrations into other less disruptive energy, such as heat. This damping mechanism reduces the amplitude of vibrations transmitted through the train structure to the tracks and surrounding environment and acts as an effective rail noise control solution.

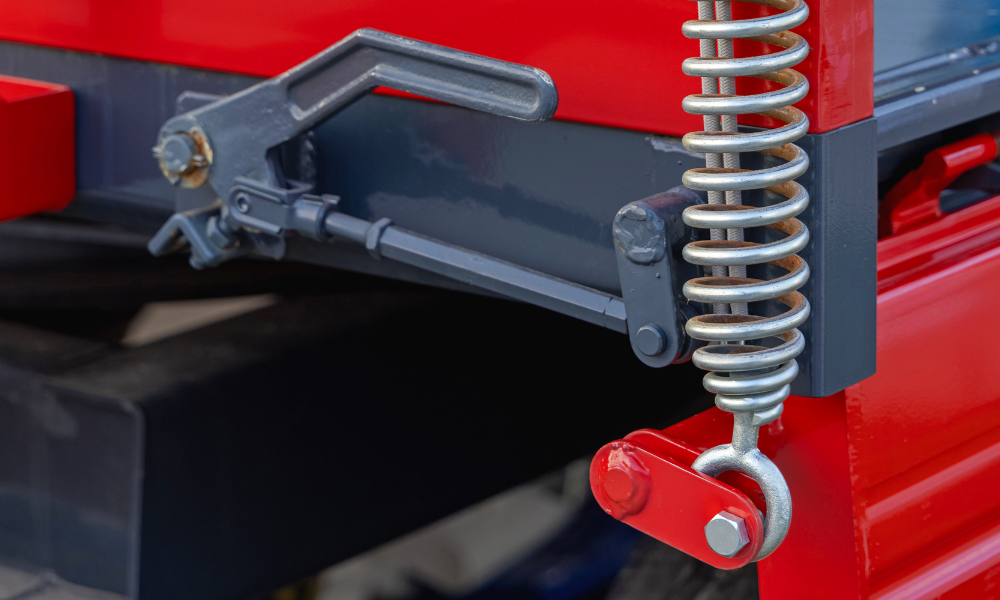

Compression springs absorb shock and dampen vibrations in railway suspension systems. Extension, torsion, leaf, and rubber-metal springs are also used in railway components, such as brake assemblies and switch controls.

Compression springs are used in train undercarriage systems due to their durability and ability to handle high dynamic loads; this improves stability and ride comfort. They are also used in buffer systems to absorb energy and reduce impact force between train cars.

Extension springs are used in couplings and brake assemblies, as they bring components back together after being pulled apart. They help maintain tension and facilitate controlled movement in various parts of the railway infrastructure.

Torsion springs exert rotational force or torque. They control movements and manage mechanical stress and are used in switch controls for railway tracks. They are also used in locking mechanisms.

Leaf springs support heavy loads and absorb shocks. They help maintain rail alignment by evenly distributing weight and reducing vibrations during train operations. Leaf springs are used in freight wagons and older passenger cars to provide durability and stability.

Heavy springs offer a range of silent benefits that improve overall railway system performance and support rail noise reduction.

Using heavy springs in trains' suspension systems improves ride quality by reducing vibrations and shocks from the track. This leads to a smoother, quieter, and more comfortable journey.

Heavy springs support rail noise control, minimising the impact of rail transport on nearby communities. This reduces complaints about noise pollution from trains.

Heavy springs reduce wear and tear on rail tracks and rolling stock by reducing vibration. This leads to lower maintenance needs and a longer lifespan of equipment.

Heavy springs improve operational efficiency by maintaining proper alignment and tension in the railway system. This reliability reduces downtime caused by mechanical failures and allows for more consistent and timely service schedules.

Best practices use advanced technology and strategic design to reduce sound levels. This includes using noise barriers, optimising track geometry, and using quiet wheel technology. Maintenance work also plays a role, as well-worn tracks and wheels can increase noise levels. Using vibration-dampening systems and materials with sound-absorbing properties can also help reduce the environmental impact of rail noise, reducing the complaints to the local authority and the number of statutory nuisances reported.

Future innovations in rail noise control will likely focus on developing materials with improved noise-absorbing properties and active noise-cancelling technologies. Predictive maintenance using AI may also play a significant role. However, these technologies must align with sustainable practices to meet environmental standards.

Heavy-duty springs offer a solution to reduce rail noise as they absorb vibrations and sound and transform them into other forms of energy. Compression, tension, torsion, leaf, and rubber-metal springs are used in railway systems; each has its advantages, and there are many benefits to using heavy springs in rail transport.

At Lesjöfors, we manufacture high-quality compression, tension and torsion springs for various industries. With spring manufacturing for railways starting in our formative years in 1852, we have been at the forefront of innovation and manufacture for the rail industry’s springs for decades. Contact our expert team to learn more about our design, engineering, and manufacturing services.

Do you need guidance to select the best material for your custom spring?

At Lesjöfors, we work with a large range of materials and hold the largest global stocks of chrome silicon and chrome vanadium anywhere in the world. We can also optimise your spring performance with top-quality materials such as steel, copper and titanium alloys and super alloys, such as Inconel, Hastelloy and Nimonic.

Get in touch with our expert team to receive expert guidance and find out how to order a custom spring.

Yes, rail noise can disturb local wildlife, particularly species sensitive to low-frequency vibrations and irregular sound patterns. It can also affect human health by contributing to stress and sleep disruption.

In most cases, train-induced vibrations are unlikely to cause structural damage. However, properties very close to the track may experience minor cosmetic issues like hairline cracks, particularly in older buildings.

Several factors contribute, including ageing infrastructure, tight curves in urban areas, and the widespread use of mechanical braking systems. Gaps in track maintenance and older rolling stock also play a role.

Train noise travels easily over long distances, especially in open terrain or at night when background noise is lower. Low-frequency sounds from engines and braking systems are particularly persistent.

Effective rail noise reduction involves a combination of strategies, including noise barriers, rail lubrication, modern suspension systems, and heavy-duty springs that absorb vibration at the source.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.