Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

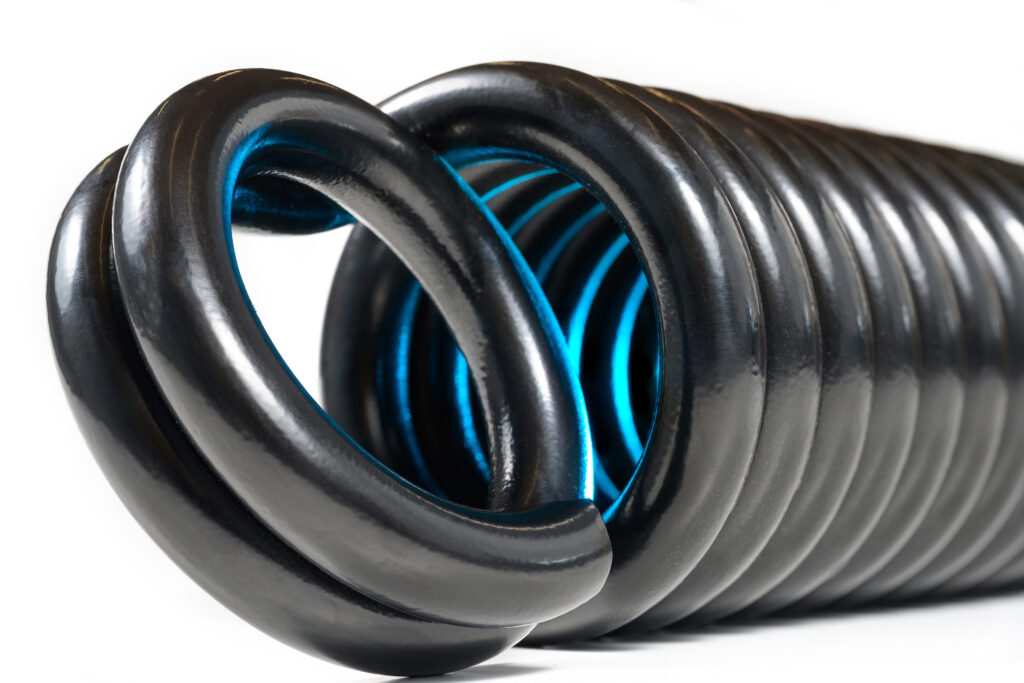

Extension springs (also known as tension springs) are used across a variety of industries, from construction and agriculture to robotics and motorsports. Here at Lesjöfors, we manufacture millions of extension springs every year, and with hot and cold coiling capabilities, we can produce custom springs for almost any application.

If you require custom-made springs for your project, then taking accurate measurements is important. In this post, we’ll break down how to measure an extension spring into seven easy steps to ensure you get the best performance possible.

Before you start, you’ll need a micrometre or callipers (a tape measure may suffice for larger measurements), and a pen and paper to write down your results.

The first measurement you should take is the wire diameter. This is the thickness of the wire used in the spring, which will determine how strong and flexible the final extension spring is. Using your micrometre or callipers, measure across the wire on any part of the spring to decipher its diameter. Ideally, you should measure in 2 or 3 places, and if there’s variance, take an average of your results.

The next part you should measure is the outside diameter, which is the width of the spring coil. Taking a tape measure or callipers as appropriate, measure across the width of the coil from the outer edge of the wire on one side to the outer edge on the other. Ensure you measure the diameter at the widest point as sometimes this can vary along the length of the spring. If in doubt, take multiple measurements.

The body length of an extension spring is how long the main part of the spring is when not under tension, excluding the hooks or loops at either end. To calculate the length of this part of the spring, use your tape measure or callipers to measure from one end of the spring body to the other, outer edge to outer edge.

The free length of an extension spring is how long the spring is overall, including the hooks or loops at either end. When the spring is not under tension, measure from the outside edge of the hook at one end to the outer edge of the hook at the opposite end.

Measuring the hooks or loops at either end of an extension spring correctly is key as this is how it attaches to the other components. To ascertain hook length, measure from the outer edge of the spring coil to the outer edge of the hook. Measure both ends for consistency.

Next, you need to determine the diameter of the loop or hook. To do this, measure across the hook from the outer edge of the wire to the outer edge on the opposite side.

On extension springs, the gap between the top of the coil and the tip of the hook is how it fits onto other components in its given application, so getting this right is crucial. To measure the hook opening on an extension spring, use callipers to determine the space from the outer edge of the coil to the end of the hook.

While these seven steps cover the essentials of how to measure an extension spring, there are additional factors to consider when ordering custom springs.

The material of an extension spring will determine its strength, durability and elasticity, so it helps to know what material the spring should be made of. At Lesjöfors, our expert team can access most materials from various steels and copper to titanium alloys. We also hold one the largest stocks of chrome silicon and chrome vanadium in the world. If you are unsure which material you need, let us know your application and we can advise on the optimum choice to meet your performance requirements.

We also need to know the hook or loop type and orientation to ensure the extension spring fits within its desired application. There are various hook types available for extension springs, such as a full loop with offset, a double German loop or a V hook. Each offers slightly different performance characteristics, so choosing the right one for your project is important.

The orientation of the hook or loop can vary too. Some hooks sit at a 90-degree angle from one another, or they can be in line. Also, they may need to open on the same side or the opposite depending on their final use. For certain applications, the coil direction can be relevant too.

Measuring an extension spring is quite straightforward, but there are some pitfalls you should watch out for. Make sure the spring you are measuring is intact and undamaged as this can alter your results. It’s also best practice to take multiple measurements for accuracy. Also, be careful not to press too hard when using devices such as callipers as you can deform springs and skew your results.

When ordering bespoke extension springs, precise measurements are important to ensure the product fits and performs well. Taking these measurements is simple though, just follow these steps and bear in mind the considerations we raised such as hook type and materials. At Lesjöfors, we have 170 years of spring manufacturing experience and state-of-the-art production facilities. We’re world leaders in heavy-duty springs, designing and manufacturing to custom specifications across diverse industries. Find out more about our custom extension springs or contact us now to talk to our expert team.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.