Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

Torsion springs are staple components in many mechanical devices. This post will support you to measure a torsion spring, so that you can use this information to calculate other important spring factors such as torque, spring constant (k) and load capacity.

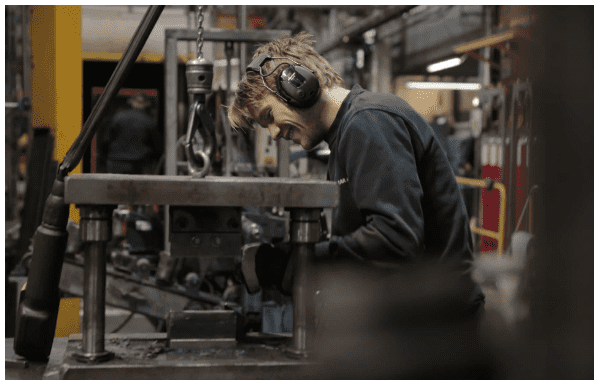

At Lesjöfors, we are world leaders in heavy-duty torsion spring manufacturing. We use advanced hot and cold coiling facilities to produce high-quality torsion springs for a range of industries across the globe.

Firstly, determine the wind direction. Hold the spring in front of you with the legs pointing towards you. If the coils run clockwise from the centre, it is a right-hand wound spring; if they run counterclockwise, it is a left-hand wound spring. By understanding the wind direction, you can ensure the spring is compatible with the mechanical system.

Next, use a calliper to measure the wire’s thickness. Measure several points along its length to determine the wire size and ensure consistency. Record the average diameter, as variations can impact the spring's load-bearing capacity and functionality. Understanding the exact wire diameter allows for precise spring design and application calculations.

Use a calliper to measure the inside diameter of the spring. The ID is the distance between one side of the coil and the other (inside the coil). You may want to position the calliper at 90° while measuring to prevent misreadings. Knowing the ID of a torsion spring will help you match the spring to the correct shaft or housing.

Next, use a calliper to measure the distance across the widest part of the spring, from the outer edge of one coil to the outer edge of the opposite coil. This measurement will help you ensure that the spring fits within its designated space.

Count the number of coils and multiply this by the wire diameter you previously measured. This calculation will give you the length of the coiled section. Then, measure the lengths of the spring's legs, or straight sections, and add these to the coiled length. These combined coil measurements will give you the total length of the torsion spring.

Accurate measurements of torsion springs are needed for correct calculations of torque, spring constant (k), load capacity, deflection, and stress levels. These calculations are important for spring design and development. Inaccurate measurements may lead to poorly fitted springs that have reduced efficiency and are susceptible to failure. Using precise measurements supports your torsion spring's maintenance of reliability and safety in applications.

Here is a list of recommended essential and optional tools for measuring torsion springs.

Here is a list of best practices for accurate measurement of torsion springs.

These practices will help you accurately measure torsion springs and understand whether they align with their intended applications.

Measurement issues with torsion springs may arise due to several factors, including poor tools, inconsistent measuring techniques, and environmental factors

To prevent the above common problems, we recommend regular tool calibration, ensuring that staff are trained to use uniform techniques, and measuring springs in a controlled environment to minimise temperature-induced fluctuations. We also suggest using high-quality measurement tools and thorough quality-control processes to identify and correct measurement inconsistencies.

When purchasing heavy-duty springs, prioritise understanding the specific load and stress requirements to ensure optimal performance and safety. With the support of our expert technical team, you can take accurate measurements and select spring materials that enhance performance, safety, and life span. We recommend testing your spring prototypes and samples before production to ensure that your spring meets the required specifications for its application

At Lesjöfors, we have innovated a range of heavy-duty springs for product solutions all around the world. We deliver the greatest expertise in large-diameter compression, torsion and tension spring manufacturing and can tailor solutions to your custom needs. We combine state-of-the-art machinery with innovative design and development solutions, plus engineering expertise so that you can optimise your spring's performance and success. Contact our expert team to discover high-performance spring solutions for your product.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.