Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

In the world of mechanical engineering, where meticulous design meets the demand for reliability, compression springs emerge as integral components, enabling the harmonious operation of diverse machinery.

From everyday items like pens and door handles to complex machinery in automotive and industrial sectors, compression springs play a pivotal role in optimising the performance of diverse applications.

Compression springs are mechanical devices designed to resist compressive forces, essentially acting as a buffer that can compress and return to its original form when the force is removed. These springs are one of the most common types of springs and are used in a wide range of applications.

Compression springs are versatile and critical components in many systems, providing the necessary resistance to compressive forces and maintaining the integrity of the system under various loads. Their design, material, and dimensions are tailored to meet specific functional requirements in diverse applications.

The choice of material for a compression spring depends on factors like required strength, flexibility, environmental resistance (such as to corrosion or temperature extremes), and cost. For example, while stainless steel provides excellent corrosion resistance, it might be overkill for an application where a cheaper carbon steel would suffice. Conversely, applications requiring high strength and durability need performance alloy materials capable of withstanding high stress levels, whilst in extremely high temperature and corrosive environments we may call upon super alloys such as Inconel and Elgiloy.

These coiled wonders, are experts at storing and releasing energy, extending their impact across an array of sectors, from healthcare and automotive engineering to consumer goods. Their remarkable adaptability and precision make them indispensable contributors to enhanced functionality, efficiency, and safety in various products.

In the healthcare sector, where precision is paramount, compression springs find themselves convoluted into the fabric of medical devices. From the subtle intricacies of surgical instruments to the delicate mechanisms within diagnostic equipment, to hospital bed equipment, these springs play a pivotal role.

Various medical devices incorporate compression springs. For example, syringes use springs for controlled injection, inhalers, pump sprays, blood testing lancet kits and glucose monitoring sensors all use compression springs. Their controlled and reliable movements contribute to the accuracy and effectiveness of medical technologies, ensuring the seamless operation of devices crucial for healthcare professionals.

The automotive industry, with its emphasis on performance and safety, relies heavily on the elaborate workings of compression springs. These springs are embedded within suspension systems, clutch mechanisms, and a myriad of automotive components.

Compression springs play a crucial role in the suspension systems of vehicles. They absorb shocks and vibrations, providing a smoother ride and contributing to overall vehicle stability.

Their presence ensures the efficient functioning of systems, impacting everything from ride comfort to braking mechanisms. Compression springs are the unsung heroes beneath the hood, optimising both the performance and safety standards of vehicles.

In industrial machinery, where productivity is the cornerstone, compression springs assume a key role. From the automated accuracy of production lines to the robust functionality of heavy machinery, these springs facilitate controlled motion.

Their adaptability to varying loads and conditions makes them indispensable in optimising the efficiency and longevity of industrial machinery, contributing to the reliability of countless manufacturing processes.

Compression springs ensure optimal functionality, found within the mechanisms of switches, connectors, the buttons on remote controls or the power button on gadgets and various electronic components. These springs provide the necessary force for reliable and consistent performance.

Their reliability extends beyond individual components, impacting the overall dependability of electronic and electrical devices, ranging from everyday gadgets to complex machinery.

Compression springs seamlessly weave into the very essence of consumer goods, improving the functionality and durability of products we encounter in our daily lives. Whether ensuring the efficient operation of household appliances or facilitating controlled movements within toys, these springs elevate the overall user experience.

For example in the world of bedding, compression springs, also recognised as coil springs, find their purpose within mattresses. Their common application is to furnish support and distribute weight uniformly, playing an essential role in crafting a sleeping surface that is not only functional but also contributes to a comfortable and restful night's sleep.

Their remarkable adaptability in managing various loads and delivering controlled force ensures that consumer goods transcend mere functionality, embodying reliability to meet the rigors of everyday use.

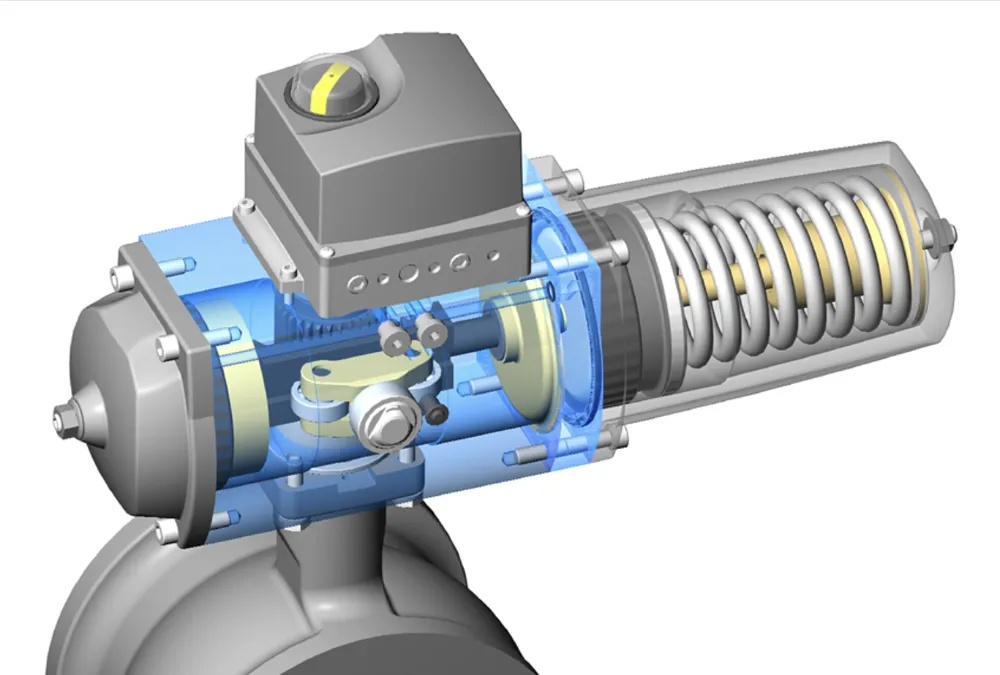

Fluid control systems, crucial components across diverse industries, hinge upon accuracy and efficiency in valves and actuators. Compression springs play a pivotal role in ensuring the accuracy of these systems.

These springs not only provide the essential force required for the efficient operation of valves and actuators but also contribute significantly to the overall reliability of fluid control systems. Their adaptive nature and controlled force delivery are paramount in maintaining the integrity of these systems, guaranteeing consistent and precise fluid flow.

In the intricate landscape of industrial processes, compression springs emerge as necessary elements. Their significance extends beyond mere functionality, encompassing critical applications that span a spectrum—from intricate manufacturing processes to the complexities of large-scale industrial setups. As silent contributors, compression springs uphold the seamless functioning of these systems, ensuring operational excellence and reliability in every fluid control application.

Compression springs contribute significantly to the function of exercise equipment, impacting the health and fitness industry. Whether in resistance machines, where they control resistance levels, or in the mechanisms of gym equipment, these springs play a crucial role.

Their controlled resistance enhances the effectiveness of exercise routines, contributing to the overall experience in fitness and wellness.

In applications where minimising vibrations is critical, compression springs are employed to isolate and dampen vibrations. This is particularly important in sensitive equipment, machinery, and structures where vibration control is essential for maintaining optimal performance and preventing structural wear.

Compression springs maintain stability and performance in environments where vibrations pose a challenge, impacting the performance of equipment across various industries.

Beyond standardised applications, compression springs showcase their adaptability in custom solutions tailored to unique specifications. From specialised machinery requiring precise force control to experimental setups with distinct engineering needs, these springs underscore their flexibility and precision.

Their role in custom applications highlights their ability to meet specific and diverse engineering requirements across a wide spectrum of industries.

Compression springs appear as silent powerhouses, seamlessly integrating into an array of industries to optimise functionality and enhance operational efficiency. Distinguished by their ability to absorb and release energy, they have become indispensable components across sectors, embodying the epitome of precision and reliability.

From automotive systems to aerospace applications and manufacturing processes, the adaptability and precision of compression springs underscores their significance as ubiquitous elements in modern machinery.

The potential of compression springs extends beyond their physical form; they embody precision, resilience, and versatility. Whether absorbing shocks in automotive suspension systems, contributing to the smooth operation of door handles, or providing controlled resistance in exercise equipment, these springs play pivotal roles in optimising various aspects of our daily lives.

In conclusion, the potential of compression springs is boundless. Their ability to efficiently store and release energy, coupled with their adaptability to diverse applications, makes them foundational components in the tapestry of engineering. As we continue to innovate and push the boundaries of technology, let us not overlook the humble compression spring—quietly but forcefully shaping the world around us.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.