Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

We specialise in manufacturing and supplying heavy duty custom compression springs to meet the unique needs of industry. Our high-quality springs are designed to improve performance, reliability, and durability across a variety of applications.

Solution providers, our innovative teams deliver exceptional engineering expertise, custom designing your compression spring to your exact specifications. Our engineers are leaders in their field, and our state-of-the-art manufacturing facilities ensure your compression spring performance achieves optimum success.

Heavy-duty compression springs are the strongest of the coil spring range.

Designed and manufactured to manage the extreme demands of the environment they perform in, our design process evaluates the stress, temperature and corrosive risks endured by the product, to guarantee a highly engineered heavy-duty compression spring delivering on quality, endurance and accuracy.

We supply heavy-duty compression springs for numerous industries, including renewables, automotive, mining, rail, construction, energy, motorsport, industrial machinery and many more.

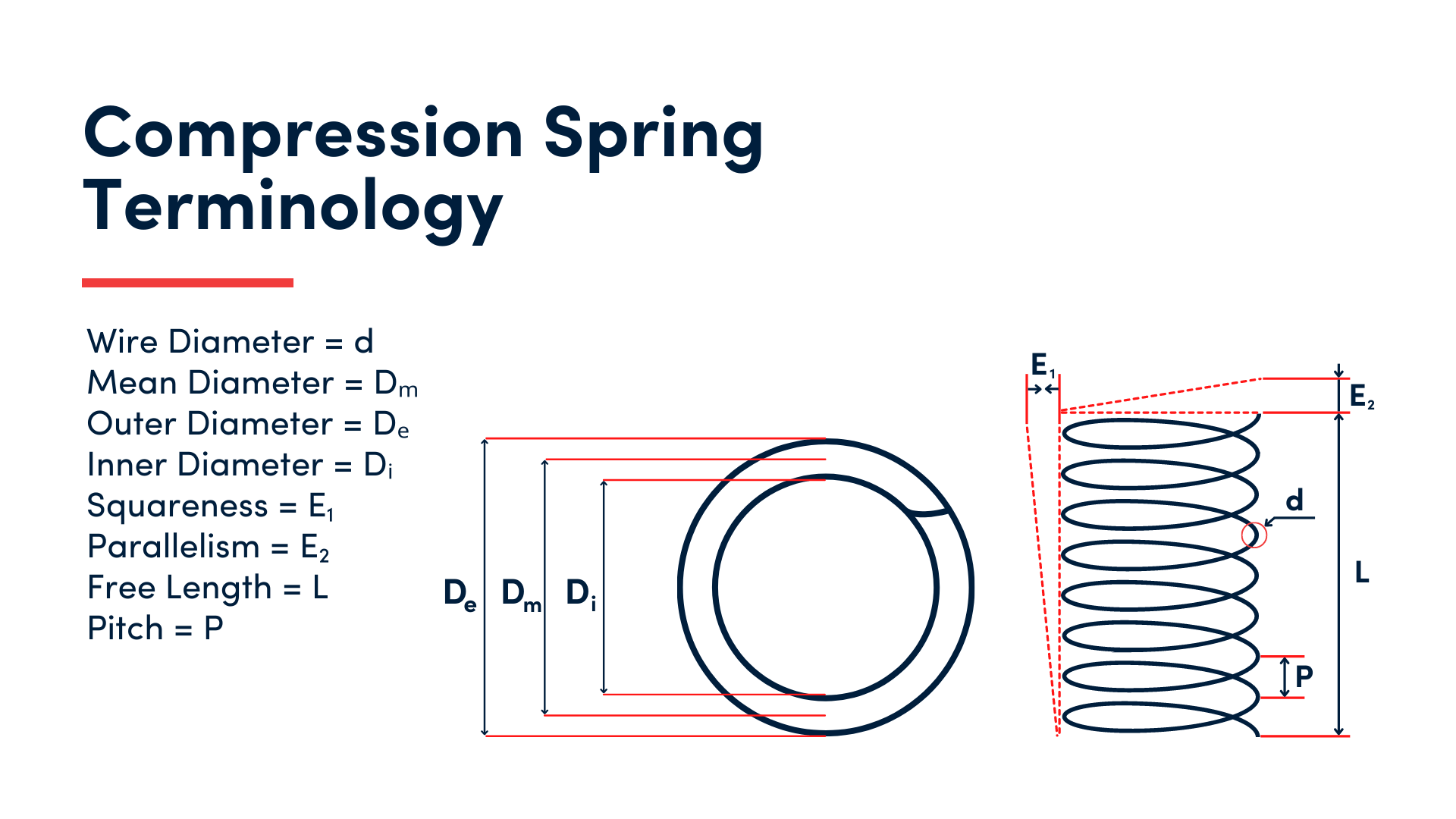

Compression springs have a unique design with a compressed helix shape that allows them to resist compressive forces.

Applying a heavy load to the compression spring forces it to compress and condense, the wire spaces then reduce in size until the spring’s wire touches, reaching the spring's maximum compressed length.

The coils provide an opposing force when compressed - storing the force until it is released. This mechanism is crucial in applications like shock absorbers and adjustment mechanisms. Find more about spring terminology.

Read how compression springs work

Read how compression springs work

Our compression springs are built to last, providing superior performance and durability for heavy-duty applications. We manufacture a wide range of wire diameters, and our expertise and precision manufacturing process ensure that every spring meets the highest quality standards.

Our compression springs are designed to deliver exceptional performance and durability, making them the premium choice for heavy-duty applications.

Allocated team of experts ensuring that the final product meets all requirements and specifications.

Creating a precision spring solution that enables you to test the requirements of your product before going into full production.

We hold one of the largest global stocks of chrome silicon and chrome vanadium wire anywhere in the world, so that we can meet the needs of our customers and deliver as a preferred spring supplier.

Our experienced engineers are unmatched and advise on all material decisions. As part of a global network of spring engineering material scientists, we guarantee that your metal spring will perform at peak with the right material for the right application.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy duty spring solutions.

Lesjöfors Heavy Springs offers a consultancy service. Our teams are available to discuss any engineering and technical issues regarding heavy spring specifications. Explore our Heavy Duty Extension Spring and Torsion Spring pages.

Compression springs are helical springs that provide resistance to compressive forces. They are commonly used in various industries for applications such as automotive suspensions, industrial machinery, and consumer products.

We manufacture compression springs using high-quality materials such as stainless steel, carbon steel, and alloy steel. The choice of material depends on the specific requirements of the application.

Yes, we specialise in custom compression springs. Our experienced engineers can design and manufacture springs according to your specific needs and specifications.

The lead time for our compression springs varies depending on the complexity of the design and the quantity required. We strive to deliver orders within the agreed-upon timeframe.

Yes, we can provide samples of our compression springs for testing and evaluation. Contact us to discuss your sample requirements.

Feel free to reach out to us.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.