Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, Lesjöfors Heavy Springs delivers a competitive environment dedicated to quality, accuracy and customer satisfaction.

Our advanced hot and cold coiling technologies and manufacturing capabilities enable us to coil springs from 3mm to 65mm wire diameter. The expertise of our engineers across our global network of manufacturing sites offers a unique level of experience in the field of heavy duty springs, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy duty spring solutions.

With wire coiling diameters of up to 65mm, heavy duty springs are the largest and strongest of the coil spring range and are designed and manufactured to manage the extreme demands of their application.

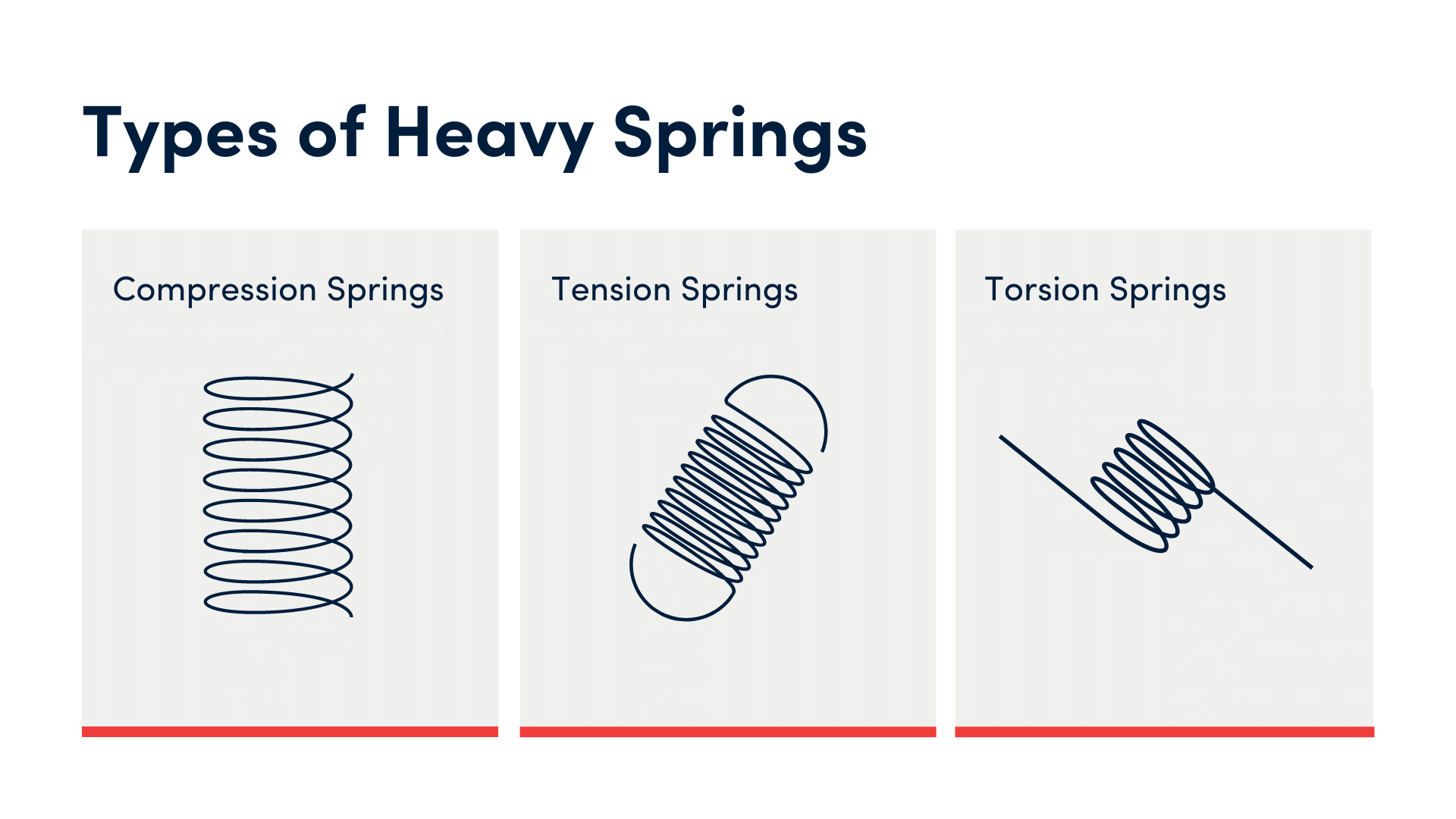

We are experts in custom heavy duty coil springs across compression springs, torsion springs and tension springs. Three types of springs that deliver different functionality across a variety of applications for multiple sectors.

With one of the largest global stocks of chrome silicon and chrome vanadium wire in the world, steel springs are available in a range of materials, and there are very few spring materials we can’t access or work with.

Your choice of spring materials is entirely governed by the application and function that your spring requires. Our engineers assess the stress, temperature and corrosive risks your product endures and advise and work with you to identify the suitable spring material for your heavy duty spring purpose.

We are world leaders in heavy spring manufacture, delivering the greatest expertise in large diameter compression, torsion and tension spring manufacturing.

Market-leading solution providers we are committed to manufacturing excellence, reliability and customer service, specialising in heavy duty spring components across industries as varied as oil and gas, mining and crushing, agriculture, construction, energy, transport and power generation.

We know springs, we know spring materials and our unique global design, manufacturing and technological development network is dedicated to service, quality and accuracy, coiling wire from 3mm to 65mm in diameter.

From our prototyping and samples service and consultative design and development process through to our advanced CNC automated coilers and integrated production facilities, every step of your spring journey is monitored for effectiveness and competitiveness, ensuring you receive the right product and achieve the right results, at the right price.

Lesjöfors Heavy Springs thinks, makes and solves spring solutions, building the world’s infrastructure one spring at a time.

There are many types of springs. Our field of specialism is dedicated to three different types of springs – compression springs, torsion springs and tension springs and within these three spring shapes, there is a number of different spring designs.

Heavy duty springs are available in a range of materials and our network of material warehouses offers a diverse range of metal spring material choices that can be identified either in consultation at the bespoke springs design stage or in consultation with a customer’s requirement.

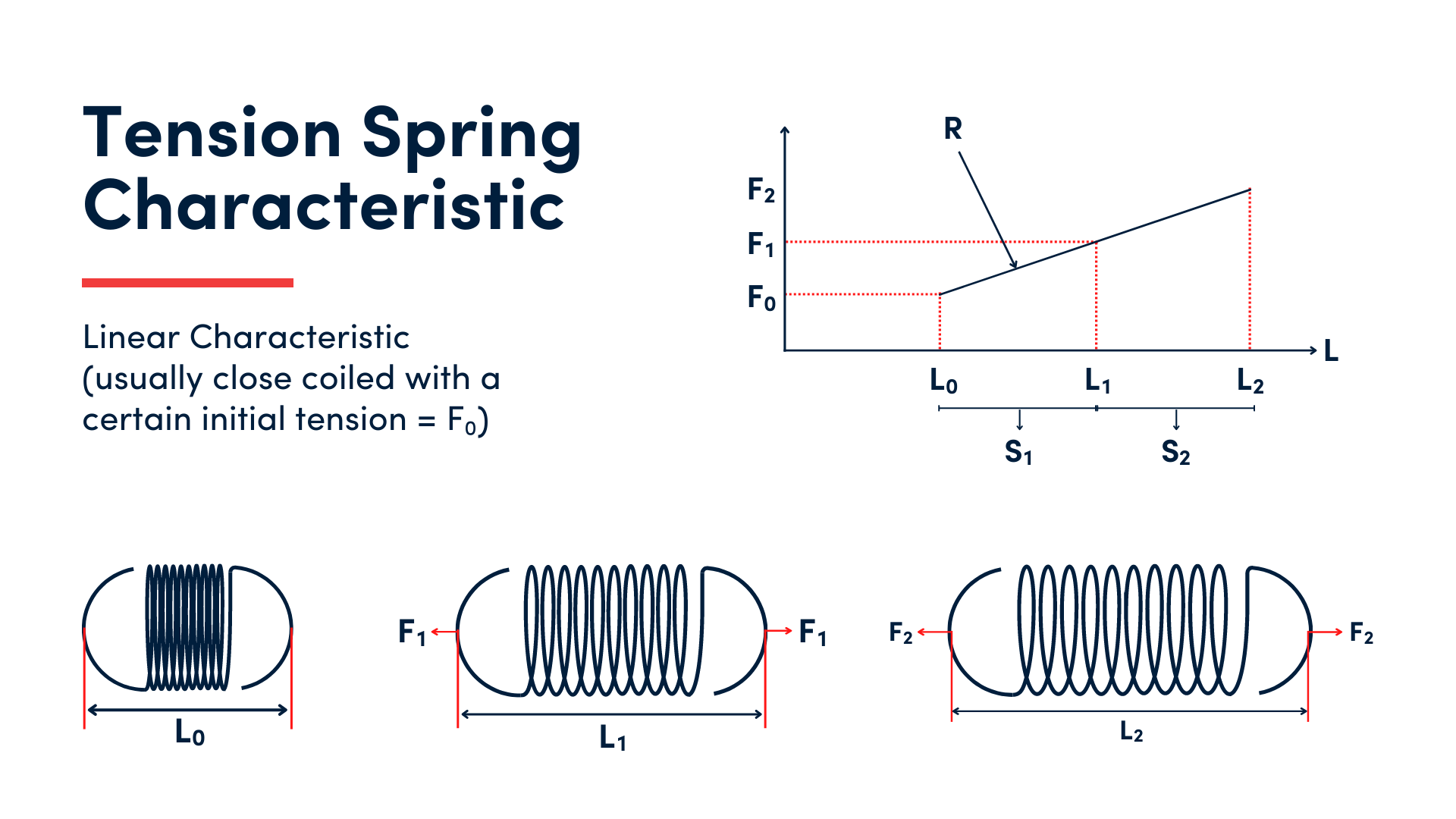

The tension spring (also known as an extension spring) has coils that are wound together, designed to give a pull force through an end fitting or loop when extended.

Heavy duty tension springs are used worldwide across applications including garage doors, elevators, agriculture, plant machinery, construction, speciality equipment and trampolines.

Our teams of heavy duty extension springs engineers are available to consult on every element of the tension spring design, advising on maximum initial tension, material choices and end fittings and loops.

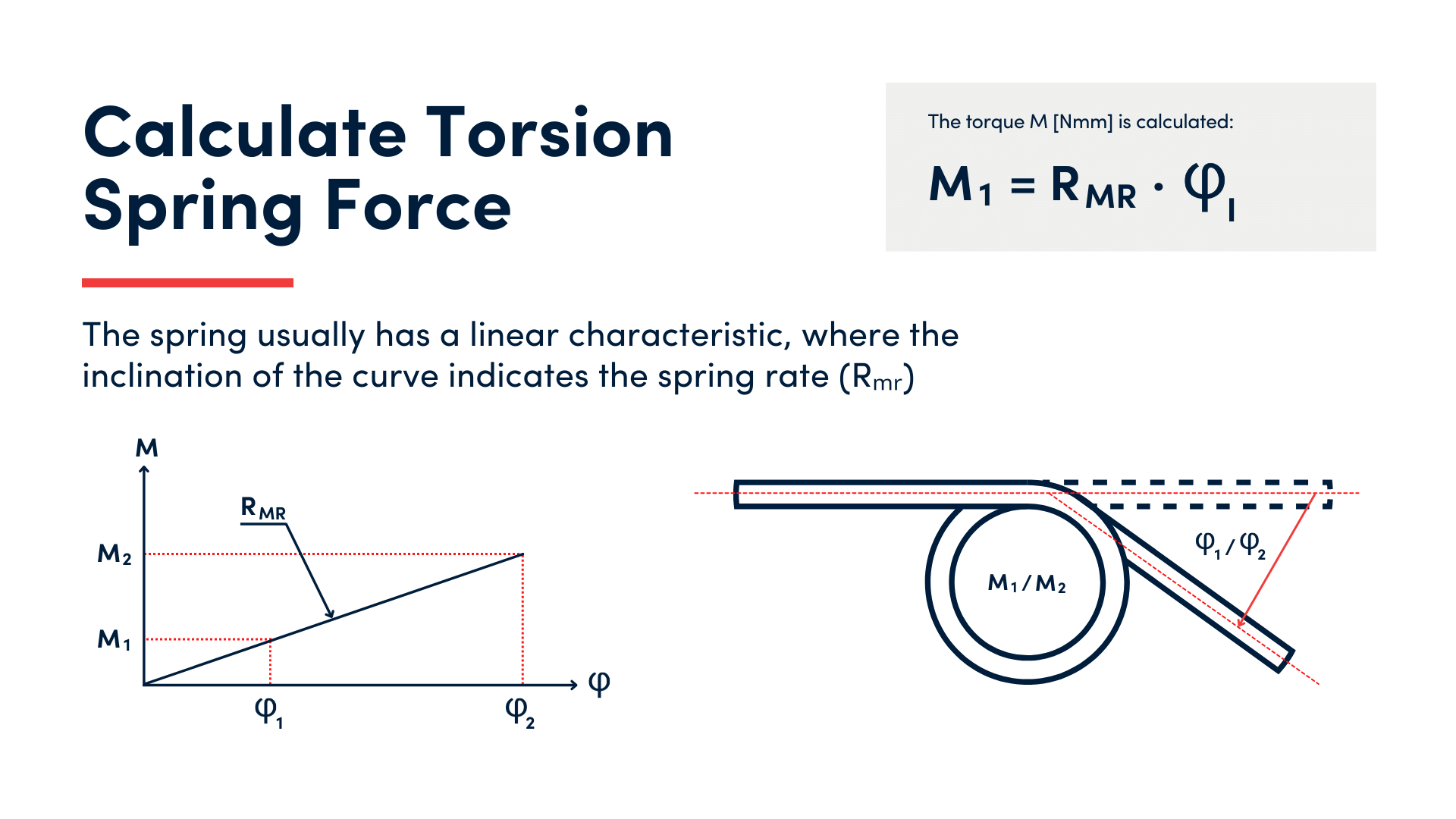

The torsion spring is a coiled spring designed to have a rotational or twisting motion that exerts a force.

Manufactured from large wire sizes, our heavy-duty torsion springs can exert an exceptionally large amount of torque when pressure is placed on it. You will find our torsion springs in tail gates of heavy plant machinery and in a wealth of other applications.

As global spring suppliers, our heavy duty spring coiling equipment features the most advanced spring technologies, including the world's largest Wafios CNC cold coiling machine.

With manufacturing facilities in excess of 30,000 sqm across the UK and Europe, featuring the spring manufacturing industries most advanced CNC coilers, 3D scanners, robotic solutions, automation, shot peening, zinc phosphating and powder coating capabilities, we can offer a one stop shop manufacturing solution and customer service that guarantees our position as a leader in the manufacturer of springs.

Spring engineering design is often led by force specification.

Through a consultative process with our engineers, we are able to calculate the spring specification for your product.

Our design engineer's key role is to support you with your compression spring design or tension and torsion spring design.

As solution providers, our innovative teams deliver exceptional engineering expertise, custom designing your spring to your specifications.

There are three main types of springs which are compression, torsion and tension springs. In addition there are disc springs, wave springs, clock springs, volute springs power springs, constant force springs and garter springs.

Springs can be manufactured from a range of materials but the most common metal spring in the heavy duty spring industry is chrome silicon due to its exceptional strength characteristics.

Material choice and spring application effects long term durability. It is not impossible for a spring to last forever. However, its performance will be affected by age and fatigue.

Springs perform an engineering function essential in the performance of millions of applications across the world.

Lesjöfors Heavy Springs manufacture the largest and strongest coil springs up to 65mm diameter and could claim to be the most robust spring – subject to spring type, material choice and operating function.

Spring engineering design calculates the right wire diameter for the right peak performance of a product specification. A thicker spring might be better for an application but is subject to that application’s need.

Heavy duty spring manufacture of compression springs, tension springs and torsion springs.

Our parent company does. We are a division of the spring powerhouse, Lesjöfors Group, which sell every spring, pressing and gas spring.

The choice of a hot coil or cold coil is predominantly determined by the size of the wire needing to be coiled.

Heavy duty springs, using a wide wire diameter commonly seen across oil and gas, mining and rail sectors require a hot winding process as the extreme heat (up to 900 degrees celsius) allows large wire diameters to be coiled.

Commonly, the wire that has already been heat-treated is cold coiled as its material is already at peak strength, allowing for numerous coil spring functions. Learn more about our processes on our spring terminology page.

Lesjöfors Heavy Springs can design, quote and manufacture products within industry-leading turnaround times at competitive prices. Please get in touch to discuss our lead times.

Our customer account teams will liaise on spring volumes. There is no minimum, but quantities are dependable on several factors. Please get in touch to discuss order volumes.

There is no fixed price as the cost depends on the material, quantity, engineering complexities and delivery timings. Please get in touch to discuss pricing

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.