Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

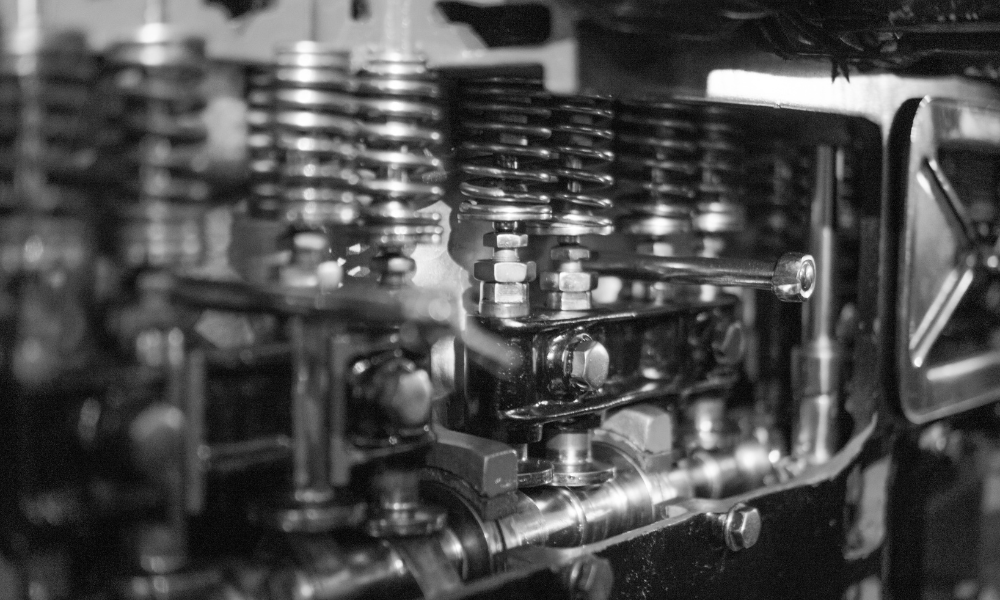

There are many different types of springs used in various mechanisms, from everyday household items to large-scale industrial machinery. In this post, you will discover five types of springs and their applications. You will also learn about the manufacturing process and materials used.

At Lesjöfors, we are world leaders in heavy-duty spring manufacturing, specialising in large compression, torsion, and tension springs. Our global manufacturing and development network is dedicated to delivering quality spring solutions that optimise your product's performance and success.

Heavy-duty springs are used in various industries, from motorsports and transport to construction and quarrying and mining. These springs act as functional components in high-performance racing cars, railway systems, power tools, drilling equipment, and more.

They absorb shocks and store energy, they provide vehicle safety and comfort, maintain suspension systems and withstand heavy loads and extreme conditions. They can also be engineered to provide precise force and motion control which makes them useful in applications such as robotics.

There are three main types of springs, compression, extension and torsion springs.

Compression springs are open-coil helical springs designed to resist compressive forces. When a load is applied to the spring, it compresses and stores mechanical energy, releasing it when the load is removed. These springs are typically used to absorb shocks, maintain a force between two surfaces, or provide a cushioning effect.

Extension springs are tightly wound helical springs designed to operate with a tensile load. They typically have hooks, loops, or other forms of attachment at both ends to connect to components that need to be held together. When the components move apart, the spring pulls them back together, storing energy when extended and releasing it when contracted.

A torsion spring is a type of helical spring that stores mechanical energy by twisting its ends along its axis. When a torsional load is applied, the spring exerts a torque (rotational force) proportional to the angle it is twisted. Torsion springs are designed to resist twisting forces and return to their original position when the load is removed, which allows controlled rotational movement.

Other common types of springs include leaf and disc springs.

Leaf springs flex under load to absorb and distribute shock and stress. They consist of multiple layers of metal (leaves) stacked and clamped together. Leaf springs are used in the suspension systems of vehicles, especially trucks, vans, and SUVs, to provide a smooth ride and maintain vehicle stability. They are also used in rail vehicles and heavy machinery due to their ability to handle heavy loads, provide stability, evenly distribute stress and withstand harsh conditions.

Disc springs, also known as Belleville washers, work by deforming elastically when a load is applied. They are conically shaped, which allows them to withstand a compression force when the spring is loaded in the same direction as the axis. When the load is removed, they return to their original shape. This design enables them to maintain tension and absorb shock or vibration in a compact space. They are used in applications requiring high force with limited space, such as in clutches, brakes and valve systems.

Common materials used to manufacture heavy-duty springs include stainless steel and carbon steel. Stainless steel provides strength and corrosion resistance, whereas carbon steel offers strength and flexibility. Alloy steels such as chrome silicon and chrome vanadium may also be used. Chrome silicon is known for its strength and resilience at higher temperatures, whereas chrome vanadium is used for its strength and fatigue resistance.

Read our ‘Heavy Duty Compression Spring Materials’ post to learn more about speciality materials, non-ferrous metals and specialised spring coatings and treatments.

You may also want to read our full coil spring manufacturing process guide.

We are committed to delivering high-quality springs with a 170-year established manufacturing legacy. With factories in the UK, Finland, and Sweden, we offer the greatest expertise in large-diameter compression, torsion, and extension springs. Plus, we use the latest cutting-edge, hot and cold CNC technologies to manufacture springs for your needs. This includes spring solutions for a range of sectors, including the automotive, energy, construction, oil and gas, rail, mining, motorsport, and agricultural industries.

We take pride in providing high-quality, custom spring solutions. Our expert design and development team will work alongside you to develop a spring tailored to your specifications. Whether you need a brand-new spring design that can withstand extreme conditions or are looking to improve an existing design, we can help. We also provide custom prototype and sample services so that you can feel confident about your spring's success before going into full production. Contact us to book your free consultation.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.