Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

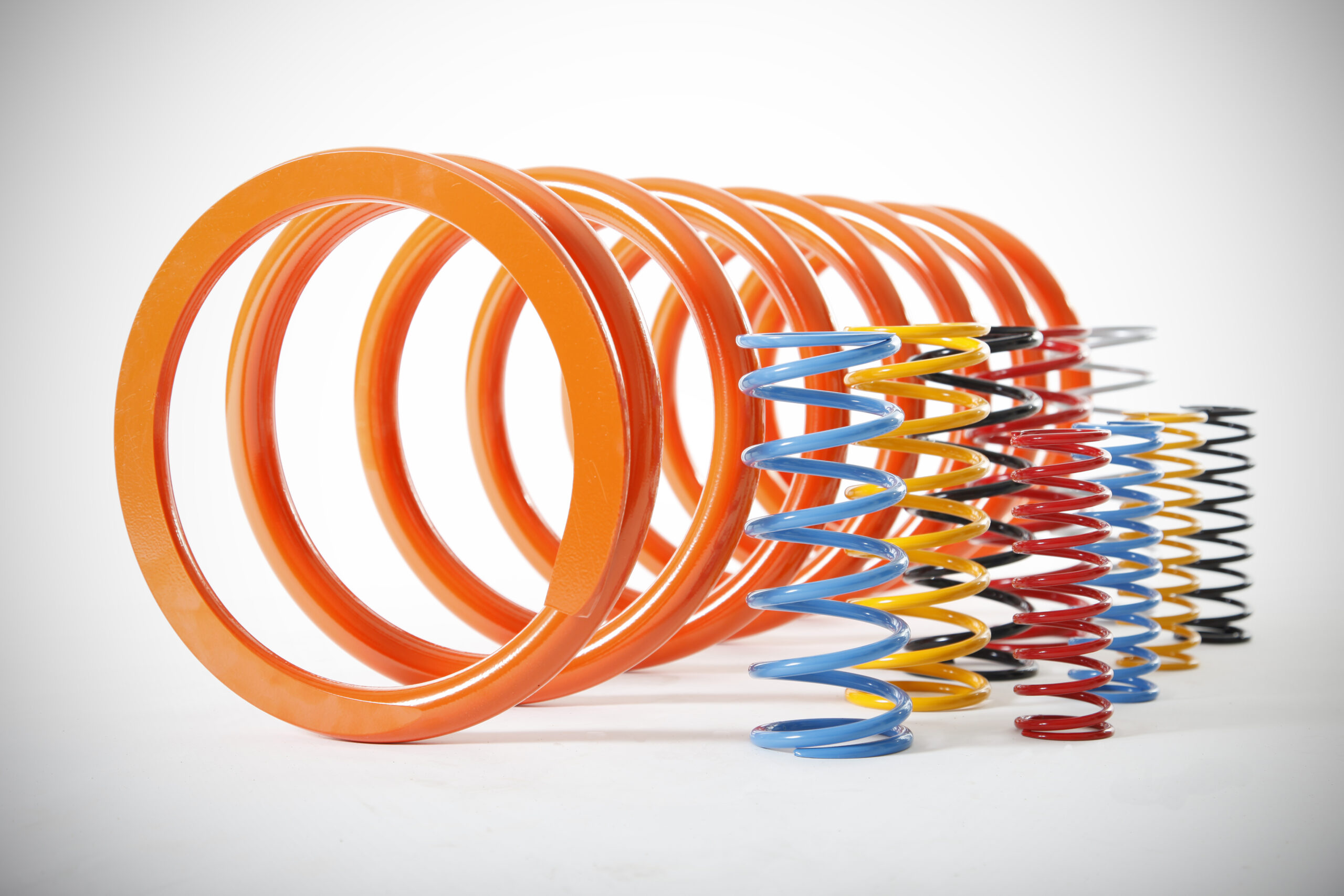

In the world of heavy-duty springs, powder coating can be an effective way to improve performance, longevity and aesthetic appeal. This type of coating is requested by a high volume of our customers, and many choose a specific colour to match their brand identity.

At Lesjöfors, we use large-scale, fully automated powder coat lines and offer a zinc phosphate coating option that delivers superior corrosive resistance. In this post, you will discover many more benefits of powder coating coil springs.

Powder coating is a dry finishing process used on a wide range of products. The powder is a mixture of finely ground pigment and resin particles. These particles are electrostatically charged and then sprayed onto the surface being coated. The coated object is then heated, causing the powder to melt and form a smooth, durable layer. This method provides superior protection against corrosion, weather, and impact, making it ideal for heavy-duty springs.

A powder coating offers many benefits for your custom spring solution. Below is a list of each benefit with a short explanation so that you can determine whether powder coating is beneficial for your spring-based product.

The electrostatic application ensures an even coating. This eliminates weak spots and enhances the durability of heavy-duty springs. It also provides a tough, wear-resistant surface that protects springs from physical damage during use.

The powder forms a protective barrier against moisture, chemicals and environmental factors that cause rust and corrosion. Our additional zinc phosphate coating option provides thousands of hours of corrosive salt spray resistance, making it ideal for ocean-based applications such as fuel extraction and drilling components.

Powder coatings may also include UV-resistant properties. This prevents degradation from sun exposure, making it suitable for commercial aircraft and transport solutions. It also prevents colour fading over time and maintains a vibrant appearance.

Powder finishes provide a smooth, uniform finish available in a wide range of colours. This allows you to customise the colour of your springs to match specific branding requirements. Different textures are also available, such as glossy and matte finishes and we facilitate a range of different colours to match your RAL and Pantone palettes.

Powder coating is faster and requires lower temperatures than traditional liquid coatings, which saves energy costs. Oversprayed powder can also be collected and reused in powder booths, reducing waste costs. The enhanced durability of the coating also extends the lifespan of a spring, reducing maintenance and replacement costs.

Its eco-friendly application process emits fewer volatile organic compounds (VOCs) than other finishing processes, making it a sustainable choice.

There are various types of powder coatings used on heavy-duty spring solutions.

Epoxy coatings are used for their superior adhesion, chemical resistance and mechanical strength. They are ideal for industrial applications where UV resistance is not needed.

Polyester coatings offer excellent weather and UV resistance, making them suitable for springs exposed to outdoor conditions.

Epoxy-polyester hybrid coatings combine the strengths of epoxy and polyester. This type of coating provides good overall durability, chemical resistance, and aesthetic qualities for both indoor and outdoor applications.

Here is an outline of the powder coating process for heavy-duty coil springs.

First, springs are cleaned to remove dirt, oil, or contaminants. This step may involve methods such as sandblasting and chemical cleaning to ensure a smooth, clean surface.

Next, a chemical pre-treatment is applied to improve adhesion and corrosion resistance. At Lesjöfors, we offer a zinc phosphate coating option that delivers superior corrosive resistance.

The powder is then applied using an electrostatic spray gun which gives an even, uniform coating over the springs.

The coated springs are then placed in an oven and heated to a specific temperature. This is usually between 160-210°C and melts and cures the powder into a smooth, durable finish.

The springs are then removed from the oven for cooling. They then receive a quality control inspection to ensure a consistent, high-quality finish.

Powder coating can be applied in a variety of colours, thicknesses and finishes for your custom needs. At Lesjöfors, we are continuously expanding our colour palette, and we take pride in supporting customers with custom spring projects. We can also support you with printing individual part numbers on your products, plus plate your springs through our subcontracted services.

Contact our expert team to make an inquiry about powder coating.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.