Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

In the high-octane world of Formula 1 racing, heavy-duty springs optimize handling and performance in racing cars. Precision-engineered springs deliver superior suspension and offer a cutting-edge, competitive advantage for championship success.

In the high-octane world of Formula 1 and car racing, heavy-duty springs optimize handling and performance. Precision-engineered springs deliver superior suspension and offer a cutting-edge, competitive advantage for championship success.

At Lesjöfors, we have a legacy of supplying race teams with precision coil springs and are trusted by some of the biggest suspension spring suppliers.

In this post, we will outline the different components in suspension systems, the types of springs used in motorsport and their impact on performance.

Let’s get started.

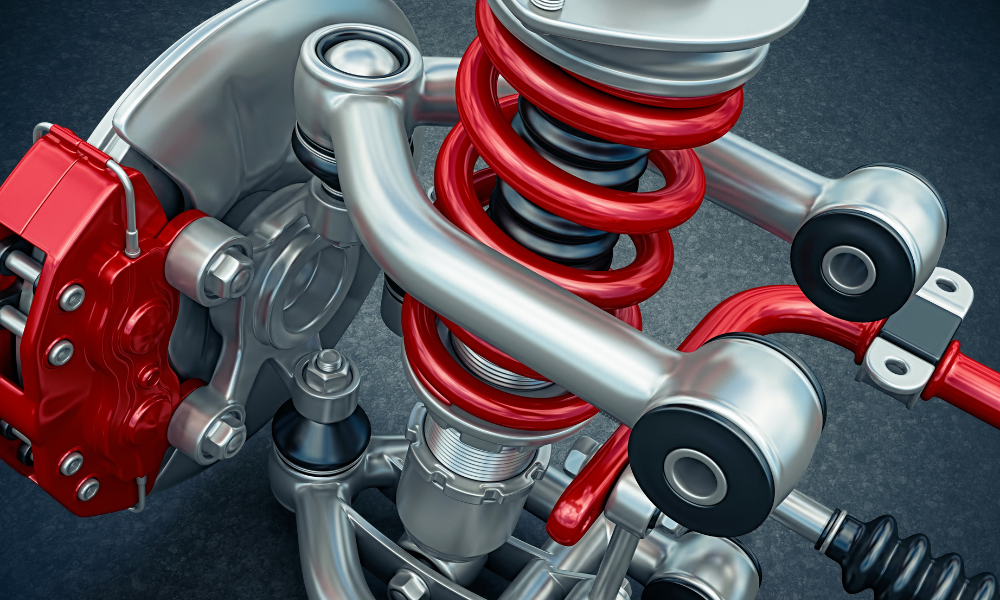

A racing suspension system is key to optimal race performance. It connects the chassis to the wheels and includes components such as springs, shock absorbers and linkages, which work together to manage wheel motion and vehicle dynamics. The main function of the suspension is to absorb shocks from the track while maintaining tyre contact with the road. This enables effective braking, steering, and acceleration.

Components that contribute to the success of a suspension system include:

Championship-winning, high-performance motorsport vehicles are created when the above components are combined with precision-engineered coil springs.

Compression springs are used in motorsport to absorb impact and store kinetic energy. This improves the ride and performance over bumps, potholes, and curbs. It also improves handling as race cars swiftly change direction or when a driver suddenly brakes. By absorbing and dissipating energy from impacts and vibrations, springs support maximum efficiency and allow vehicles to cope with the extreme demands of high-speed circuits.

Compression springs, torsion springs (bars), and Belleville springs are used in Formula 1 cars. These springs handle high dynamic loads, provide twisting forces in compact locations, handle small deflections and enhance performance.

Here is a quick overview of each type of spring used in Formula 1 racing.

Compression springs are the most traditional type used in suspension systems, known for their durability and ability to handle high dynamic loads.

Torsion springs, also known as torsion bars, use twisting forces to provide spring action. Known for their compact design, they are usually mounted longitudinally in the car and connected to the suspension arms. This allows teams to fine-tune the car's stiffness and handling characteristics to certain track conditions.

Belleville springs are washer-type springs that handle high loads with small deflections; these are used primarily within the clutch system rather than the suspension. Their design allows them to handle high loads with limited movement, which makes them ideal for applications requiring large forces within small spaces.

In Formula 1, pull-rod and push-rod suspensions are two configurations used to optimise car performance in the back and front suspension systems. Both systems include dampers, springs and anti-roll bars, allowing precise adjustments to the car’s handling and suspension stiffness. Let’s look at each system.

A push-rod suspension uses a rod connected to the wheel hub. This rod pushes up against a rocker, which operates the spring and damper high in the car's chassis. This setup is beneficial for aerodynamics and weight distribution. Most modern Formula 1 cars use push rods, which are easier for F1 teams to install than pull rods.

A pull-rod suspension works similarly but inverts the mechanism, with the rod pulling on a rocker mounted low in the chassis. This setup lowers the car's centre of gravity and is often used for its aerodynamic advantages. Pull-rods were the earlier suspension systems used in Formula 1 cars, although they may be used to reduce the overall height of the suspension assembly.

Interestingly, push-rods and pull-rods may also be combined in suspension configurations. For example, Red Bull’s RB20 uses a pull-rod in the front and a push-rod in the rear suspension. After witnessing its strong ride and aerodynamic performance, other rivals have considered using this layout. The push-rod in the back changes the floor space and narrows the gearbox layout, whilst the pull-rod supports airflow around the front tyres.

The use of springs in Formula 1 cars significantly enhances durability and performance. Here are five ways that springs benefit the performance of motorsport vehicles.

The FIA (Fédération Internationale de l'Automobile) governs Formula 1 and sets specific rules regarding the materials, dimensions, and characteristics of springs used in the suspension systems. These regulations ensure safety, fairness, and competitive balance. Teams must adhere to these guidelines when designing and implementing their suspension components, including springs, to comply with the technical standards and pass the required inspections before racing.

Heavy-duty springs provide high-performance solutions for the motorsport industry, absorbing impact and improving ride, handling and speed. The three common types of springs used include compression springs, torsion springs (bars), and Belleville springs. Compression springs are the most commonly used in suspensions and can be used in push-rod and pull-rod suspension systems.

With a legacy of supplying race teams with precision coil springs, we understand the various extreme racing requirements to which spring products must adhere. We also know that every event has different coil spring needs, from the Dakar Rally and Indianapolis 500 to the Isle of Man TT, Formula Racing, and the Goodwood Festival of Speed.

Lesjöfors works with various motorsport disciplines, including superbikes, rallying, motocross enduro, cross country, autocross, road racing, karting, circuit racing, and Formula 1. Most of our motorsport design, development, and manufacturing projects involve creating custom suspension springs for motorcycle racing and high-performance race cars.

We pride ourselves on continual research and development and investment in technologies and our teams, which positions us at the forefront of motorsport spring manufacturers.

Contact our expert team today to learn more about custom motorsports springs.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.