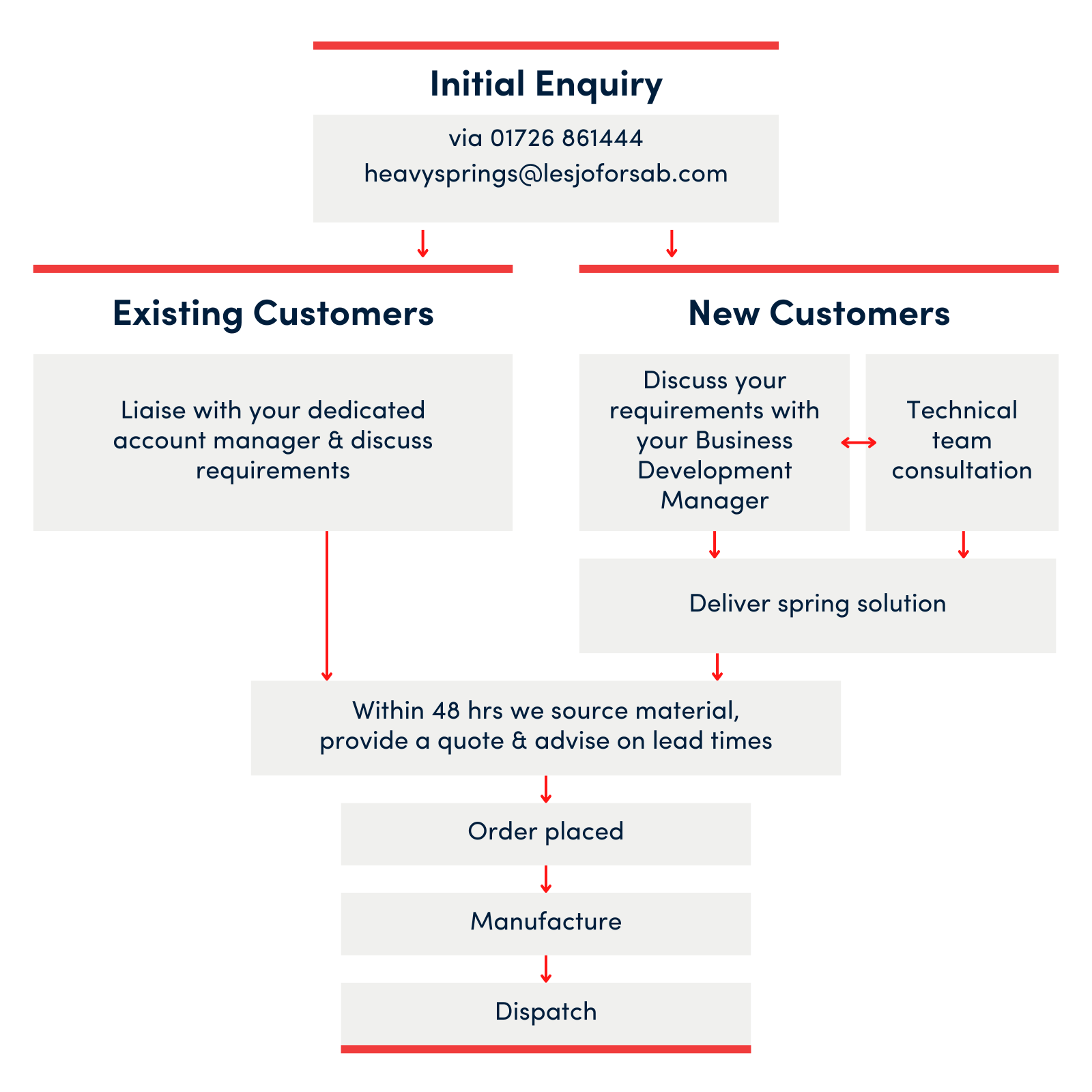

Please complete the form below, and one of our experts will be in touch.

If you would like to send a technical drawing with your enquiry, please email heavysprings@lesjoforsab.com

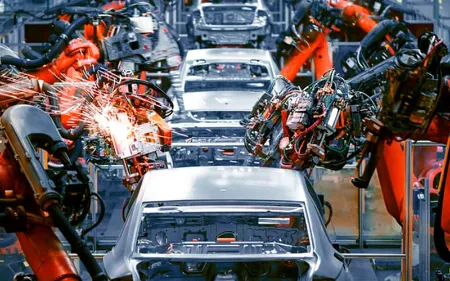

We proudly develop and manufacture automotive aftermarket suspension springs for every car brand and are recognised as the industry’s leading premium suspension spring manufacturer.

Our high-quality, precision engineered springs deliver the accuracy, quality and essential critical safety required by spring components across multiple applications within a wide range of vehicle types.

We continually invest in the best and can design, quote, manufacture and dispatch your product within industry leading turnaround times at competitive prices.

From one to one million springs and beyond, there are no limits to the volume of spring manufacturing we offer.

We can help improve your supply chain and gain efficiencies through volume manufacture by stocking and storing your spring products. To discuss further, please contact your account manager or get in touch at heavysprings@lesjoforsab.com.

Require a certain type of freight, need your product packaged a specific way? Let us know how you would like your product packaged and our dispatch team will handle the rest.

Maximising the potential of a spring by delivering exceptional design, development and manufacturing production processes is a key part of our customer experience methodology. It is also the winning performance formula behind a spring component’s success. Our audited, tested, recognised and reliable multi-stage manufacturing process guarantees the competitiveness and quality of your product.

The most distinguishing property of a coil spring's material is its mechanical strength and elasticity. The four key components when considering material choice are chemical composition, surface property, tensile strength and size. These essential elements build the structure from which our engineers bespoke design springs, to meet the demands of the application of springs within the transport industry and to optimise the purpose and power.

We are dedicated to delivering engineering excellence with a quality personal service and want to ensure that your journey from enquiry through to coil spring manufacture to dispatch is simple, seamless and excels at securing the spring solution you require.

With a 170-year manufacturing legacy and state-of-the-art production and commercial infrastructure, we deliver a competitive environment dedicated to quality, accuracy and customer satisfaction, guaranteeing Lesjöfors Heavy Springs as the premium partner for your heavy-duty spring solutions.

All our customers have dedicated account managers that oversee every step of the commercial and production process. Our team become an extension of your team, proactively positioned to understand and secure your requirements, to fast-track any urgent projects and to listen to your business needs.

From supercars to SUVs, lorries to horseboxes, buses to road sweepers to rail braking systems and aeroplane infrastructure, there’s a tension spring, compression spring or torsion spring, likely coiled by us across multiple transportation systems throughout the world.

Suspension is a core part of our compression spring applications. However, you will also find our springs in seating, door functions, brake applications, steering systems and in a wealth of other vehicle performance functions.

Matching our customers world-class performance expectations with advanced production technology and leading expertise, our technical, quality, engineering and production teams enjoy partnerships with leading industrial transportation, LCV, car and motorcycle brands.

The majority of our projects involve designing, developing and manufacturing custom springs for an essential function required for the transportation of goods - whether people, animals or trade materials.

All our projects start with consultations; establishing drawings to meet precise specifications and designing prototypes and samples that evolve as the product design process evolves. Vehicle performance handling assessments, technical reviews, safety testing and failure analyses collaborate to direct the demands of the precision spring and secure the right bespoke coil spring performance for the vehicle’s functionality and environment.

The expertise of our experienced engineers is unmatched. As part of a global network of spring engineering material scientists, you can guarantee that your metal spring will perform optimally with the right material for the right function.

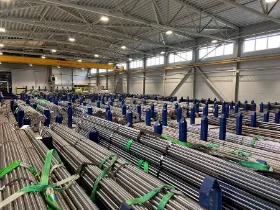

There are very few metal spring materials we can’t access or work with. We hold one of the largest global stocks of chrome silicon and chrome vanadium wire anywhere in the world.

We also work with a diverse range of steels, copper and titanium alloys, as well as super alloys, including Inconel, Hastelloy and Nimonic.

We’re leaders in our field because we manufacture from the highest quality wire and feature the most advanced coiling and cutting technology. This results in us excelling at spring manufacturing standards within the transport industry, delivering spring solutions that deliver the right product for the right application and guaranteeing uniformity and precision from the first spring to the last.

An essential part of the manufacturing process, heat treatment removes residual stress introduced to the material during the coiling process. The treatment stabilises the springs dimensions for greater accuracy and increased fatigue life and our oven facilities use forced convection technology to ensure the material is uniformly heat treated from surface to core. Our larger transport industry springs (such as for rail), using a wider wire diameter, require a hot winding process as the extreme heat allows large scale wire diameters to be coiled.

The process of heating up wire to approximately 900 degrees celsius, quenching in oil and tempered to complete the heat treatment, allows the spring material to be coiled to the specifications required.

Our quality management systems conform to ISO 9001 and our teams are experts in their field. Our global network of quality engineers ensure the spring products meet the quality standards required by the design and are the one stop shop for quality control and spring manufacturing standards within the transport industry.

Our wide material stocks allow us to source the most suitable alloy spring wire for manufacture. Marrying the right material choice with the latest in software design for suspension spring manufacture means we are able to produce increasingly efficient designs, resulting in weight saving, which in turn leads to increased fuel efficiency.

We are very fortunate to be able to partner with leading names within the transport industry, to further our R&D through partnerships with them and in turn be at the leading edge of smart suspension thinking and systems.

Our exceptional expertise, advanced technologies, material scientists, stocks, insights and research facilities enable us to consistently explore advancements in our spring products. From lightweight materials, efficient energy recovery systems, advanced braking systems, noise reduction and active aerodynamics, we are working on a number of projects that explore all these factors. We will continue to develop these areas further to guarantee our position as the best solution for our customer’s transport spring needs.

Limitations come down to the application requirements of the spring, material choice and tolerances. Our engineers are the best at optimising the potential out of spring designs.

Once the design and manufacturing process is approved, we can produce your springs when you need them. Our OTD is exceptional.

Absolutely. We welcome knowledge sharing and our engineers are always on hand to consult and support.

We are world-leading heavy duty spring manufacturers, delivering the greatest expertise in compression, torsion and tension spring manufacturing.

Delivering impact to every industry, we guarantee spring solutions that will optimise your performance and success.